Top Suppliers for ER70S-6 Welding Wire with Quality Assurance and Competitive Pricing

The Importance of Choosing the Right ER70S-6 Welding Wire Supplier

Welding is a critical process in various industries, including construction, manufacturing, and automotive. One of the essential components of successful welding is the type of welding wire used. Among the numerous options available in the market, ER70S-6 welding wire has gained significant popularity due to its excellent performance in multiple applications. However, selecting the right supplier for ER70S-6 welding wire can greatly impact the quality of your work.

Understanding ER70S-6 Welding Wire

ER70S-6 is a solid, mild steel welding wire that is primarily used in gas metal arc welding (GMAW) processes. It is well-regarded for its versatility, allowing it to be used in various positions and for applications like fabrication and repair. The “ER” in ER70S-6 stands for “Electrode Rod,” while “70” indicates the minimum tensile strength of the wire (70,000 psi). The “S” designates it as a solid wire, and the “6” highlights its composition, which includes deoxidizers such as manganese and silicon.

The advantages of ER70S-6 wire include its ability to produce strong welds with minimal porosity, making it ideal for welding thin to medium-thick materials. Additionally, it works well with both short circuit and spray transfer methods, providing welders with flexibility and efficiency in their operations.

Why a Reliable Supplier Matters

Choosing a dependable ER70S-6 welding wire supplier is vital for several reasons

1. Quality Assurance Not all welding wires are created equal. A reputable supplier will provide high-quality ER70S-6 wire that meets industry standards. Poor-quality wire can lead to weak joints, increased downtime, and unnecessary costs due to repairs.

2. Variety and Availability Different welding projects may require specific types and quantities of ER70S-6 wire. A good supplier will have a diverse inventory, ensuring that you can find the right specifications for your project while avoiding delays caused by backorders.

3. Technical Support A reliable supplier often offers technical assistance or guidance. This support can be invaluable, especially for businesses new to welding or those tackling complex projects. They can help with selecting the right wire for applications, improving welding processes, and troubleshooting any issues that arise.

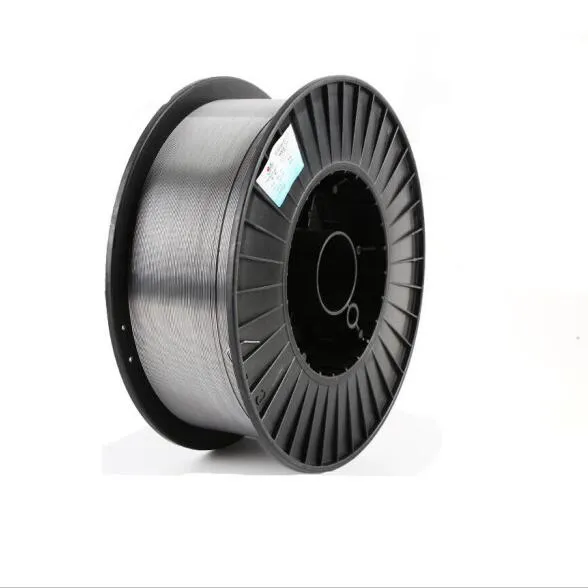

er70s6 welding wire supplier

4. Cost-Effectiveness While price is an important consideration, it should not be the only factor when selecting a supplier. A supplier that offers high-quality products at competitive prices can provide cost savings over time by reducing wastage, rework, and project delays. Additionally, some suppliers may offer bulk purchase discounts or loyalty programs that further enhance savings.

5. Reputation and Reviews Researching a supplier's reputation within the industry can provide insights into their reliability. Customer reviews and testimonials can reveal much about their service quality and the grade of their products. Opting for a supplier with a solid track record can help mitigate risks associated with subpar materials.

How to Choose the Right ER70S-6 Welding Wire Supplier

1. Conduct Research Start by researching potential suppliers. Look for companies that specialize in welding products and have a strong track record in the industry.

2. Check Certifications Ensure that the supplier complies with relevant industry standards and possesses necessary certifications. This can provide added assurance of the quality of their products.

3. Compare Prices and Services Obtain quotes from multiple suppliers and compare their prices and services. Make sure that the total cost reflects not only the price per unit but also shipping and handling fees.

4. Request Samples If possible, request samples of the ER70S-6 welding wire for a trial run. This can help you evaluate the quality of the wire before making a larger purchase.

5. Evaluate Customer Support Engage with the supplier's customer service to gauge their responsiveness and willingness to assist. Reliable support can make a significant difference when you encounter issues or require assistance.

Conclusion

Selecting the right ER70S-6 welding wire supplier is a pivotal decision that can influence the success of your welding projects. By focusing on quality, reliability, and support, you can ensure that your welding operations run smoothly and efficiently. With the right supplier, you will have peace of mind, allowing you to focus on what you do best producing high-quality work that meets your clients' needs.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025