Exploring China's Manufacturing Capabilities for 7018 Arc Welding Rods in Industry Applications

Understanding China’s 7018 Arc Welding Rod Factories

Arc welding is a critical process in various industries, and the efficiency and reliability of welding rods play a pivotal role in the success of welding operations. Among the many types of welding rods, the E7018 arc welding rod is highly regarded for its exceptional performance and versatility. In China, numerous factories specialize in the production of these high-quality welding rods, contributing significantly to both local and global markets.

The Importance of E7018 Welding Rods

The E7018 welding rods are known for their excellent weldability, strength, and ductility. They are commonly used in welding structural carbon and low-alloy steels, making them ideal for construction, shipbuilding, and other heavy-duty applications. The rods are typically coated with a low-hydrogen flux, which helps prevent defects in the weld, such as cracking, porosity, and slag inclusion. This makes them particularly valuable in situations where quality is paramount.

China's Role in the Welding Rod Market

China is one of the largest producers and exporters of welding materials in the world. The country’s vast industrial base and advancements in manufacturing technology have enabled it to dominate the global market for welding rods, including the E7018 variant. Chinese factories benefit from economies of scale, allowing them to produce welding rods at competitive prices without compromising quality.

Production Techniques and Quality Control

The manufacturing process of E7018 welding rods involves several critical steps, including material selection, coating application, and quality testing. Chinese factories employ modern production techniques that ensure high levels of consistency and quality. Raw materials are carefully sourced to meet stringent specifications, and the coating process is meticulously controlled to guarantee optimal performance.

china 7018 arc welding rod factories

Quality control is a significant aspect of the production process, with various tests conducted to ensure that each batch of welding rods meets international standards. This includes tensile strength tests, impact tests, and thorough inspections of the welds produced using the rods. Consequently, customers can trust that they are receiving a product that meets the highest quality requirements.

Innovation and Sustainability

As the global demand for environmentally friendly manufacturing processes increases, many Chinese welding rod manufacturers are adopting innovative practices to reduce their environmental footprint. This includes using eco-friendly materials in the production process and implementing waste recycling programs. Additionally, advancements in production technology, such as automation and data analytics, are enabling factories to enhance efficiency and reduce energy consumption.

Challenges and Future Prospects

Despite its strengths, China's welding rod industry faces challenges such as fluctuating raw material prices and increasing competition from other manufacturing countries. However, the continuous investment in research and development, coupled with a focus on innovation, bodes well for the future of Chinese E7018 welding rod factories.

With growing markets in developing countries and the rise of advanced manufacturing techniques, Chinese factories are well-positioned to meet the evolving needs of the welding industry. They play an essential role in ensuring that high-quality welding supplies are available to welders worldwide, supporting a broad range of industries that rely on strong, reliable welds.

Conclusion

In conclusion, China's E7018 arc welding rod factories are vital components of the global welding supply chain. Through their commitment to quality, innovation, and sustainability, they not only contribute to the domestic economic landscape but also play an essential role in the international market. As the demand for robust welding solutions continues to grow, these factories will remain at the forefront, providing welders with the materials they need to deliver superior results in their projects.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

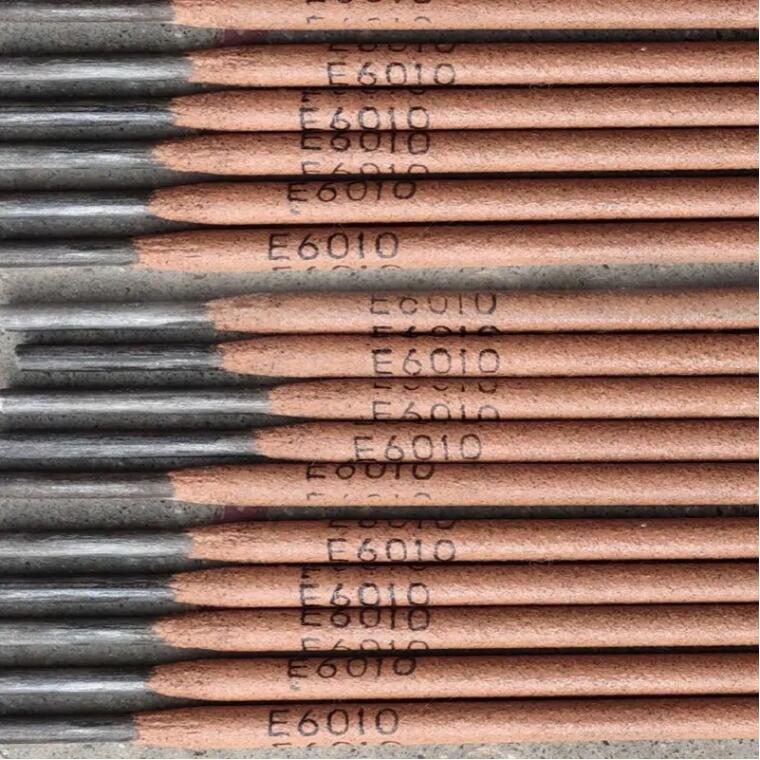

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025