Finding Reliable Suppliers for 1.6 mm Stainless Steel Welding Wire and Accessories Online

Understanding 1.6 mm Stainless Steel Welding Wire Suppliers

When it comes to welding stainless steel, selecting the right kind of welding wire is crucial for the quality and durability of the finished product. One of the most commonly used sizes is 1.6 mm stainless steel welding wire. This article aims to delve into the significance of choosing reputable suppliers for this material, along with some key considerations in the procurement process.

Importance of Stainless Steel Welding Wire

Stainless steel is widely recognized for its strength, resistance to corrosion, and aesthetic appeal. This makes it a popular choice in various industries, including automotive, aerospace, construction, and food processing. The choice of welding wire directly influences the characteristics of the weld, including its strength, ductility, and resistance to heat and corrosion. For quality welds, suppliers must offer products that adhere to industry standards and specifications.

Specifying 1.6 mm Diameter

The diameter of the welding wire is essential to achieving desired welding characteristics. A 1.6 mm diameter is typically used for thin to moderately thick stainless steel materials. It provides greater control during the welding process, allowing for more precision and less heat input, which is especially vital in preventing warping or distortion of the base materials.

Characteristics of Quality Welding Wire

When searching for 1.6 mm stainless steel welding wire suppliers, certain characteristics are indicative of quality. The wire should be made from high-grade stainless steel, typically 304 or 316 grade, which ensures good overall properties including corrosion resistance. Additionally, the wire should have a consistent diameter and smooth finish to facilitate efficient feeding through the welding machine.

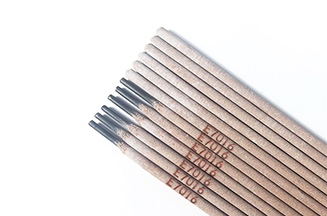

stainless steel welding wire 1.6 mm suppliers

Choosing the Right Supplier

1. Experience and Reputation It’s advisable to partner with suppliers who have a proven track record in providing high-quality welding wire. Reading customer reviews, checking for industry certifications, and seeking recommendations can be helpful in identifying reliable suppliers.

2. Product Range and Customization Suppliers that offer a wide range of products may be more capable of meeting specific needs, including different grades of stainless steel and wire diameters. Some suppliers may also provide customization options, such as spools of specific lengths, tailored to your project requirements.

3. Technical Support Quality suppliers often provide technical support to help customers select the best products for their welding applications. This may include advice on welding parameters, compatibility with different welding processes, and tips on handling and storage.

4. Competitive Pricing While cost should not be the sole deciding factor, comparing prices from various suppliers while ensuring quality standards can lead to significant savings, especially for bulk purchases.

5. Delivery and Service A reliable supplier should offer prompt delivery and excellent customer service. This is especially important for businesses that rely on timely project completion.

Conclusion

Selecting the right supplier for 1.6 mm stainless steel welding wire is a vital consideration for any welding project. The quality of the wire can significantly impact the integrity and aesthetic of the weld. By focusing on suppliers with a solid reputation, broad product offerings, technical expertise, competitive pricing, and reliable service, you can ensure that your welding operations are successful and efficient. Investing time in finding the right supplier is not just about purchasing a product; it’s about establishing a partnership that enhances your welding capabilities and contributes to the overall success of your projects.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025