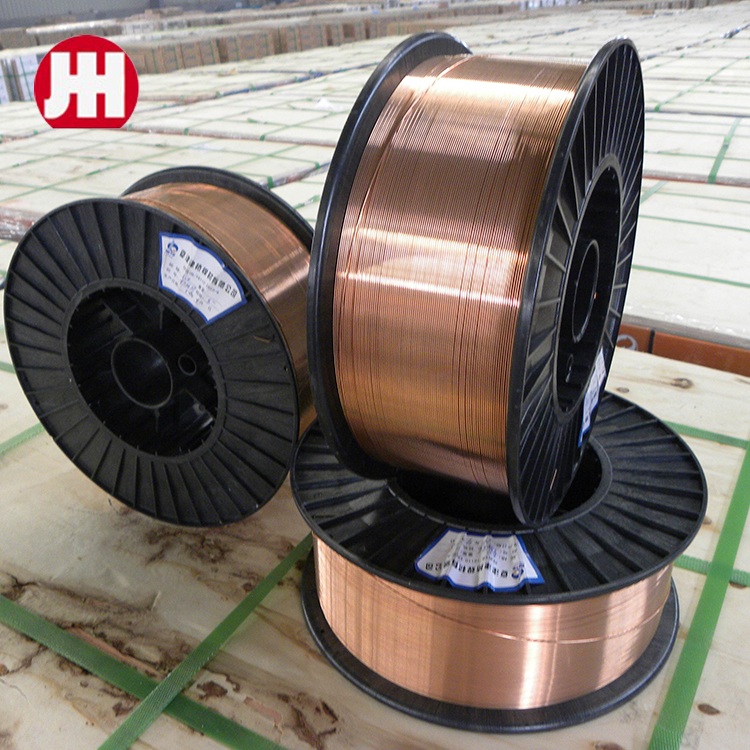

flux core solder wire

Understanding Flux Core Solder Wire An Essential Tool for Every DIY Enthusiast

Flux core solder wire is a crucial component in the world of electronics and metalworking, widely utilized for its efficiency and effectiveness in joining metallic parts. For hobbyists and professionals alike, understanding the characteristics and applications of flux core solder wire can dramatically enhance the quality of their work.

What is Flux Core Solder Wire?

Flux core solder wire is a type of solder that has a hollow core filled with flux, a vital chemical agent used to promote adhesion during the soldering process. The flux helps to clean the metal surfaces and prevents oxidation, which can inhibit the soldering process. Unlike solid solder, which requires the use of separate flux, flux core solder simplifies the operation by integrating both components into one product.

Typically made of an alloy of tin and lead—though lead-free versions are increasingly popular—the solder wire is available in various diameters, allowing users to select the perfect size for their specific application. The most common types of flux in flux core solder wire include rosin-based and acid-based fluxes, each suited for different soldering tasks.

Benefits of Using Flux Core Solder Wire

1. Ease of Use One of the standout advantages of flux core solder wire is its convenience. Since it combines solder and flux, you don’t have to apply a separate flux, which can often lead to mess and complications. Simply feed the solder wire into the joint, and the heat from the soldering iron activates the flux.

2. Improved Joint Quality The flux in the wire helps to ensure that the solder adheres well to the metal surfaces. It cleans the metal as it melts, allowing for a stronger bond and reducing the chances of defects such as cold solder joints, which can occur when the metal surfaces are not properly prepared.

3. Versatility Flux core solder wire is suitable for various soldering applications, including electronics, plumbing, and metal fabrication. Whether you are repairing a circuit board or connecting pipes, flux core solder can deliver reliable and efficient results.

4. Accessibility Readily available in hardware stores and online, flux core solder wire is often more accessible than other types of solder. Its widespread use and standardization mean that most users can find the specifications they need.

Choosing the Right Flux Core Solder Wire

When selecting flux core solder wire, there are a few factors to consider

flux core solder wire

- Composition Decide whether you want leaded or lead-free solder. Leaded solder tends to melt at lower temperatures and is more forgiving in terms of soldering technique, while lead-free solder is more environmentally friendly and is usually required for many electronics.

- Diameter The diameter of the solder wire can significantly affect its usability. Thinner wires (0.3mm to 0.6mm) are ideal for delicate electronic components, while thicker wires (1.0mm and above) are better for larger joints and plumbing applications.

- Flux Type Match the flux type to your project needs. Rosin-based flux is great for electronics as it’s non-corrosive, while acid-based flux is better suited for metalwork and plumbing, where corrosion is less of a concern.

The Soldering Process

To effectively use flux core solder wire, follow these general steps

1. Preparation Clean the surfaces you plan to solder to remove any dirt, grease, or oxidation. Use an appropriate cleaner or abrasive for the metal involved.

2. Heating the Joint Use a soldering iron or a torch to heat both parts of the joint. Ideally, the heat should be applied to the components rather than directly to the solder wire, allowing the solder to flow into the joint more effectively.

3. Applying the Solder Once the metal parts are hot enough, feed the flux core solder wire into the joint. The heat will activate the flux, allowing the solder to flow and fill the gap between the surfaces being joined.

4. Cooling and Inspection Allow the joint to cool naturally and inspect the bond. A well-done solder joint should appear shiny and smooth without excessive solder overflow.

Conclusion

Flux core solder wire is an invaluable tool for anyone involved in soldering tasks, from hobbyists to professional technicians. Its ease of use, excellent joint quality, and versatility make it a go-to choice for various applications. By choosing the right type of flux core solder wire and mastering the soldering technique, you can achieve strong, reliable connections that stand the test of time. Whether you are repairing electronics or working on plumbing projects, investing time in understanding flux core solder wire will undoubtedly pay off in the quality of your work.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025