flux core wire factories

Exploring Flux Core Wire Manufacturing A Comprehensive Overview

Flux core wire has revolutionized the way welding is approached in various industries, thanks to its unique design and functionality that make it suitable for a range of applications. This article delves into the intricacies of flux core wire factories, the manufacturing process, benefits of flux core welding, and its significance in different sectors.

Understanding Flux Core Wire

Flux core wire is a type of welding wire that contains a flux core, which melts during the welding process, providing a protective gas shield around the weld pool. This innovative design allows for better penetration and a cleaner weld compared to traditional methods. It is particularly effective for welding thicker materials and in outdoor conditions, making it a popular choice in construction, shipbuilding, and automotive industries.

Manufacturing Process of Flux Core Wire

The production of flux core wire involves several critical steps that ensure the quality and performance of the final product.

1. Material Selection The manufacturing process begins with the selection of high-quality base metals, typically steel, that will serve as the outer shell of the wire. The choice of metal depends on the specific application requirements, including tensile strength and corrosion resistance.

2. Flux Formulation The flux is a critical component in flux core wire. Manufacturers carefully blend various ingredients, such as minerals, chemicals, and organic materials, to create the flux mixture. This blend is carefully designed to provide the desired shielding properties, control the weld pool, and influence the mechanical properties of the weld.

3. Wire Formation Once the materials are prepared, the outer metal is formed into a cylindrical shape, creating a tube. This tube is then filled with the specially formulated flux, which is precisely measured and distributed to ensure uniformity.

flux core wire factories

4. Welding Wire Production The filled tube is drawn through various dies to achieve the final wire diameter. This process also helps in ensuring that the wire has the right mechanical properties, such as flexibility and tensile strength.

5. Quality Control As with any manufacturing process, quality control is paramount. Flux core wire factories conduct rigorous testing to ensure that their products meet industry standards and specifications. This includes tensile testing, chemical composition analysis, and even inspection of the welds produced using their wire.

6. Packaging and Distribution Finally, the finished wire is carefully packaged to prevent damage during transport and distributed to various markets, including construction sites, factories, and welding supply stores.

Benefits of Flux Core Welding

The advantages of flux core welding make it a preferred choice for many welders and industries

- Versatility Flux core wire can be used on a variety of materials and thicknesses, making it suitable for multiple applications. - Outdoor Performance Unlike MIG welding, which is highly sensitive to wind and drafts, flux core welding can be performed outdoors, thanks to its self-shielding capabilities. - Speed Flux core welding is generally faster than other forms of welding, which can lead to increased productivity and cost savings for manufacturers. - Less Post-Weld Cleaning The flux creates a protective slag, which often means less cleaning is required post-welding.

Conclusion

The evolution of flux core wire manufacturing has significantly impacted the welding industry, offering welders a versatile and efficient solution for various applications. As industries continue to innovate and evolve, the importance of high-quality flux core welding remains undeniable. Factories specializing in this wire must maintain stringent quality control while catering to the diverse needs of multiple sectors. With ongoing advancements in technology and materials, the future of flux core wire and its applications looks promising, paving the way for more efficient welding processes and robust welds.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

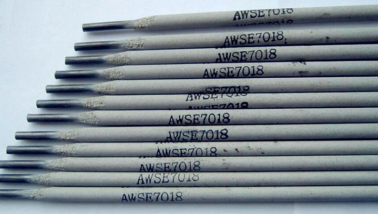

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025