High-Quality 1/16 Welding Rods from Reliable China Factory for All Your Welding Needs

The Rise of China’s 1/16 Welding Rod Factory A Deep Dive into the Industry

In recent years, China has emerged as a powerhouse in the manufacturing sector, particularly in the field of welding materials. Among these, 1/16 welding rods stand out for their versatility and widespread applications in various industries. These rods are crucial for both amateur and professional welders, offering a reliable solution for welding tasks in construction, automotive repair, and metal fabrication. The development of factories dedicated to producing 1/16 welding rods epitomizes China's commitment to meeting global demand and maintaining a competitive edge in the manufacturing landscape.

The Rise of China’s 1/16 Welding Rod Factory A Deep Dive into the Industry

One of the most significant factors contributing to the success of the Chinese welding rod industry is the country's well-established supply chain. The proximity of raw materials, such as steel and various alloys, to manufacturing facilities facilitates a smooth and cost-effective production process. Moreover, many Chinese factories benefit from economies of scale, enabling them to produce high volumes of welding rods at competitive prices. The integration of automation and robotics in the manufacturing process further enhances the capability to maintain high standards while increasing production rates.

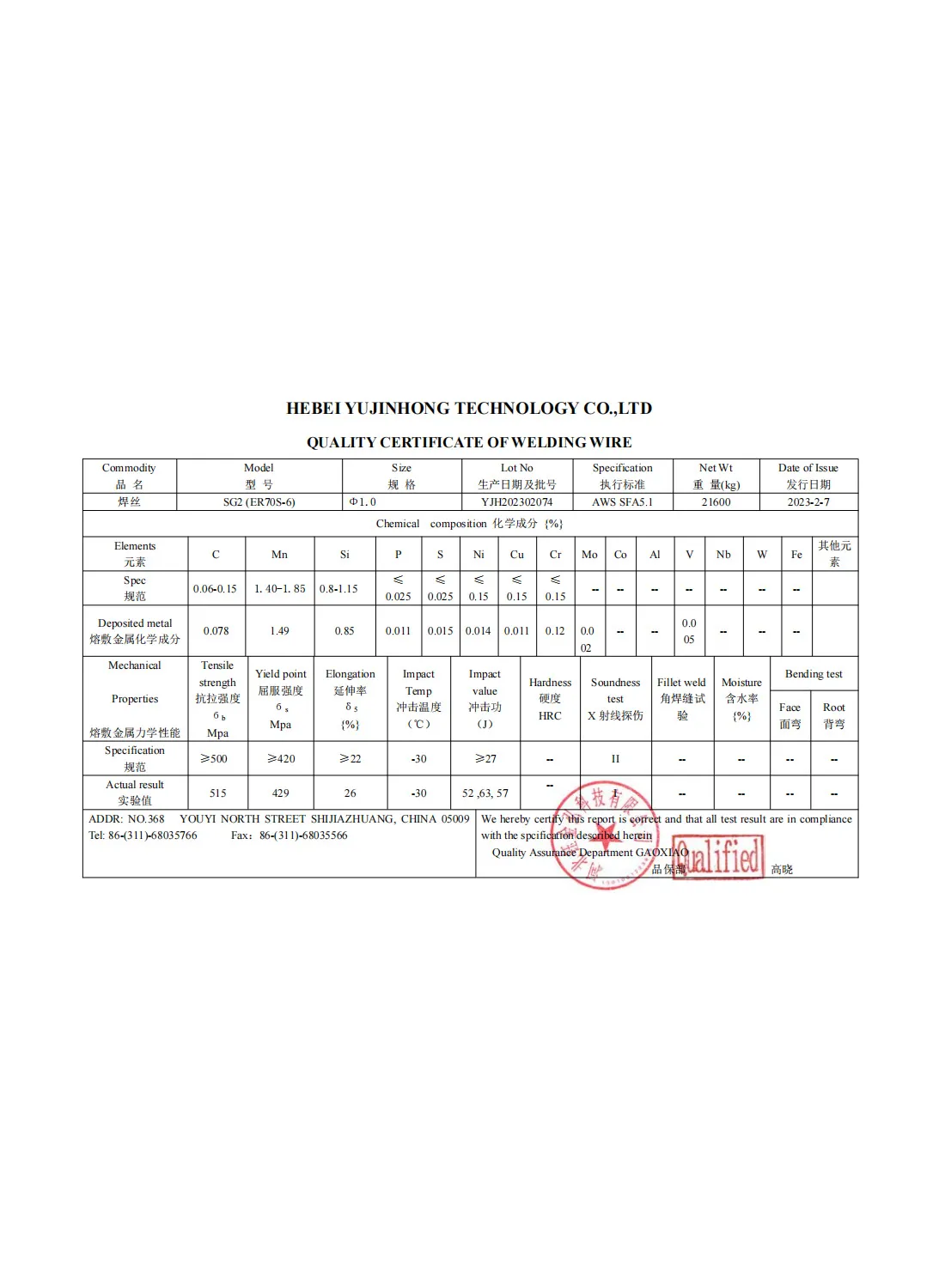

china welding rods 1/16 factory

Quality control is another cornerstone of the success of China’s 1/16 welding rod factories. To compete in the global market, these factories adhere to stringent international quality standards. Many facilities are certified with ISO and other relevant certifications, indicating that they prioritize both safety and performance. Regular audits and inspections ensure that each batch of welding rods meets the necessary specifications, which not only builds trust with customers but also helps secure long-term contracts with multinational companies.

The global market for welding materials is witnessing an upward trend, driven by increasing demand in construction, infrastructure, and automotive industries. As countries around the world continue to invest in development and modernization, the need for reliable welding rods, particularly those like the 1/16 diameter variety, remains high. China’s factories are strategically positioned to capitalize on this trend, exporting a significant portion of their production to countries in North America, Europe, and Asia-Pacific.

Sustainability is also becoming a crucial aspect of manufacturing in China. Recognizing the environmental impact of industrial processes, many welding rod factories are adopting greener practices. This includes reducing waste, recycling materials, and optimizing energy use. Companies that show dedication to sustainability not only contribute to the health of the planet but also attract environmentally conscious consumers, further enhancing their marketability.

In conclusion, China's emergence as a leading manufacturer of 1/16 welding rods is a testament to its robust industrial base, commitment to quality, and ability to adapt to market demands. With continued investments in technology and sustainability, these factories are poised to not only meet the current needs of the global market but also set the standard for the future of welding materials. As industries around the world evolve, the role of Chinese manufacturing in providing reliable and innovative solutions will be more critical than ever, solidifying China's position as a key player in the global welding industry.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025