High-Quality Welding Rods 308 from Reliable Manufacturers for Exceptional Performance and Durability

The Significance of Welding Rods in Modern Manufacturing A Focus on 308 Welding Rods

Welding is an essential process in modern manufacturing, construction, and repair industries. Among the various tools and materials that facilitate this process, welding rods play a critical role in ensuring the integrity and quality of welded joints. One particular type of welding rod that stands out in numerous applications is the 308 welding rod. This article explores the characteristics, applications, and advantages of 308 welding rods, emphasizing their significance in contemporary fabrication processes.

What are 308 Welding Rods?

308 welding rods are a type of stainless steel electrode designed primarily for the welding of austenitic stainless steels. They are composed of a chromium-nickel alloy, which typically contains about 18% chromium and 8% nickel, rendering them highly corrosion-resistant and capable of withstanding high temperatures. These rods are widely used in the gas tungsten arc welding (GTAW) and shielded metal arc welding (SMAW) processes. The designation 308 comes from the American Welding Society (AWS) specifications, indicating the chemical composition of the rod.

Applications of 308 Welding Rods

The versatility of 308 welding rods makes them suitable for a broad range of applications across various industries

. They are primarily used for1. Fabrication of Stainless Steel Structures 308 rods are commonly employed in the fabrication of stainless steel structures found in industries such as food processing, pharmaceuticals, and chemical processing. The rods' corrosion resistance is critical in these applications, where exposure to harsh chemicals and moisture is commonplace.

2. Repair and Maintenance Work The durability and strong bonding capabilities of 308 welding rods make them ideal for repair and maintenance tasks in both industrial and commercial settings. They can effectively restore the integrity of stainless steel components, reducing downtime and maintenance costs.

3. Construction and Architecture In architectural applications, 308 rods are used for erecting stainless steel frameworks, railings, and decorative elements. Their aesthetic quality and resistance to tarnishing ensure that structures remain not only functional but also visually appealing.

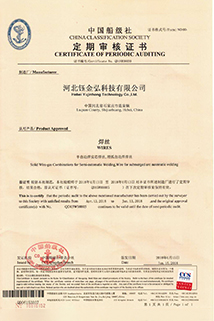

welding rods 308 factory

Advantages of Using 308 Welding Rods

The use of 308 welding rods offers several advantages

1. Corrosion Resistance The high chromium and nickel content in 308 rods provides excellent resistance to oxidation and corrosion, making them ideal for environments where exposure to moisture and corrosive substances is inevitable.

2. High-Temperature Performance 308 rods exhibit remarkable performance under high-temperature conditions, making them suitable for applications involving heat and thermal expansion.

3. Ease of Use These welding rods are favored by many welders for their ease of use and versatile application. They provide excellent arc stability, allow for smooth operations, and produce clean welds with minimal spatter.

4. Strength and Durability Welds made with 308 rods possess superior tensile strength and durability, ensuring that welded joints can withstand significant stress over time without failure.

Conclusion

In conclusion, 308 welding rods are a vital component in the toolkit of modern welders. Their unique properties make them indispensable in a variety of applications across different industries. The combination of corrosion resistance, high-temperature performance, and ease of use solidifies their reputation as one of the preferred welding rods for stainless steel fabrication. As manufacturing processes continue to evolve, the importance of quality welding materials like 308 rods will only increase, supporting the construction of reliable and durable structures that meet the demands of contemporary engineering challenges.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025