High-Quality Wholesale CO2 Mig Welding Wire Suppliers and Factories for Your Industrial Needs

The Rise of Wholesale MIG Welding CO2 Wire Factories

In recent years, the welding industry has witnessed significant advancements, particularly in Metal Inert Gas (MIG) welding technologies. One of the critical components of MIG welding is the CO2 (carbon dioxide) gas, used as a shielding agent to protect the weld pool from atmospheric contamination. As a result, the demand for high-quality CO2 wires has surged, prompting the rise of wholesale MIG welding CO2 wire factories worldwide.

Understanding MIG Welding and the Role of CO2

MIG welding is a popular welding process known for its versatility, speed, and ease of use. It involves feeding a continuous wire electrode into the weld pool, which creates a strong bond between metal parts. The use of CO2 as a shielding gas in MIG welding is favored for its cost-effectiveness and ability to produce clean welds with minimal spatter. This makes it particularly attractive for both industrial applications and DIY projects.

Wholesale MIG welding CO2 wire factories specialize in producing and distributing high-quality CO2 wires in bulk. These factories are designed to meet the growing demand from various sectors, including automobile manufacturing, construction, and metal fabrication, where reliability and performance are paramount.

Benefits of Wholesale CO2 Wire Factories

1. Cost-Effectiveness Buying CO2 wires in bulk from wholesale factories significantly reduces costs for businesses. These factories can offer competitive pricing due to economies of scale, making it an attractive option for companies looking to optimize their operational budgets.

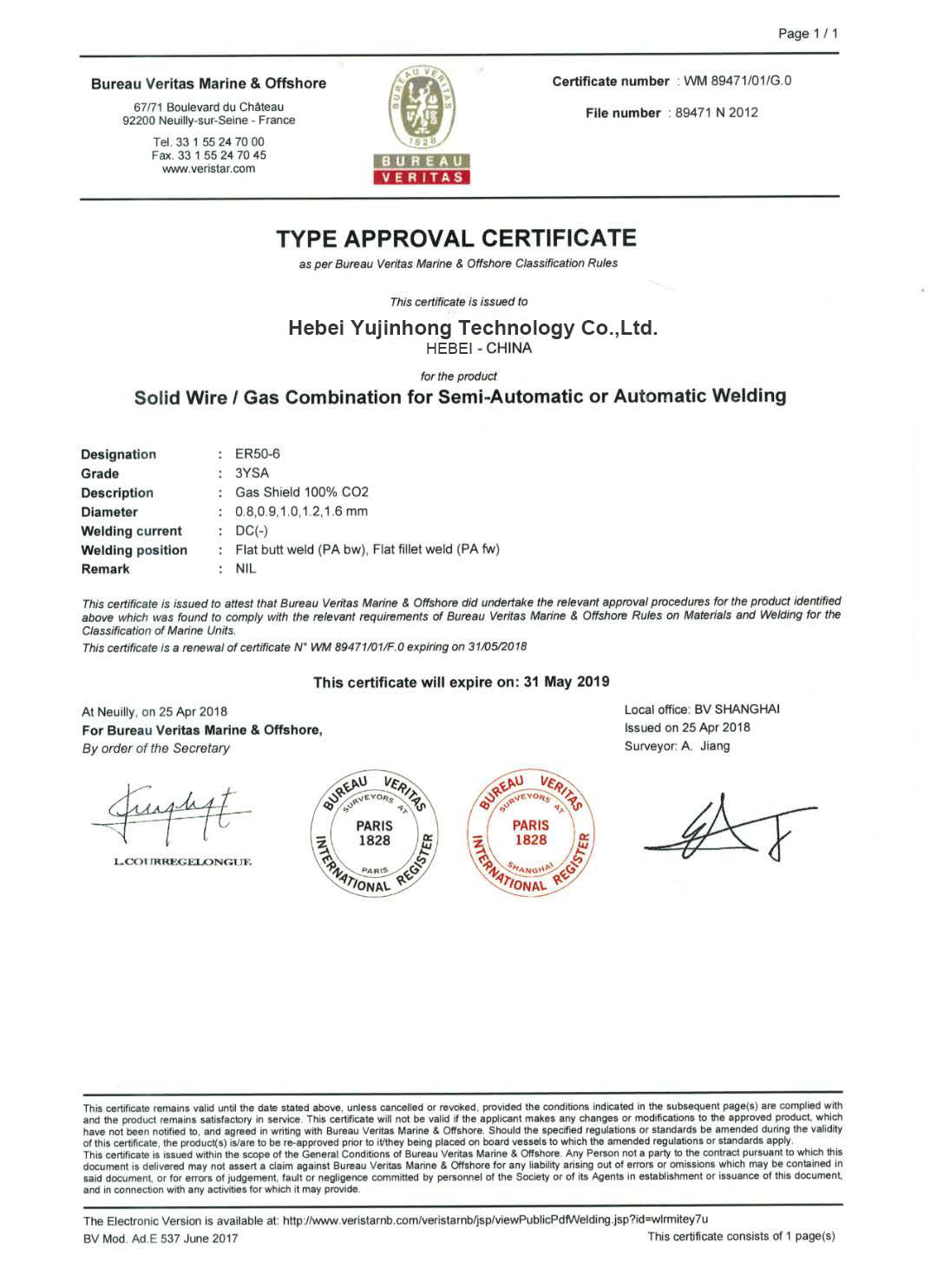

2. Quality Assurance Renowned wholesale factories invest in state-of-the-art technology and adhere to strict quality control measures. This ensures that the CO2 wires produced meet industry standards, enhancing the overall quality and durability of the welds.

wholesale mig welding co2 wire factories

3. Consistency When sourcing from a reliable wholesale supplier, businesses can expect consistent wire quality and performance. This is crucial for maintaining production schedules and meeting project deadlines without compromising on quality.

4. Customization Many wholesale factories also offer customization options for their CO2 wires. This allows businesses to choose specific wire diameters, coatings, and material compositions to suit particular welding applications, further enhancing their operational efficiency.

The Global Impact of Wholesale CO2 Wire Factories

As the demand for MIG welding CO2 wires grows, wholesale factories are expanding their reach globally. Countries with burgeoning manufacturing sectors, such as China, India, and Brazil, have seen a rise in investments for coal factories. These factories not only cater to domestic markets but also export products to regions with limited manufacturing capabilities.

This globalization has led to a more interconnected supply chain, enhancing collaboration between manufacturers, suppliers, and end-users. By fostering relationships across borders, wholesale CO2 wire factories contribute to shared technological innovations and best practices in the welding industry.

Conclusion

The emergence of wholesale MIG welding CO2 wire factories represents a significant evolution in the welding sector. With their ability to provide cost-effective, high-quality, and consistent products, these factories play a crucial role in meeting the increasing demands of modern industries. As the market continues to grow and evolve, businesses that leverage wholesale sources for their welding needs will be better positioned to succeed in an increasingly competitive landscape.

In summary, the future looks promising for wholesale MIG welding CO2 wire factories as they contribute to both the economic development of regions and the technological advancement of the welding industry. As these factories continue to innovate and expand, they will play an integral part in shaping the future of welding.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025