Manufacturers of J422 Welding Electrodes for Reliable Industrial Applications

The Impact of J422 Welding Electrodes on the Manufacturing Industry

The welding industry has seen significant advancements over the years, driven by the growing need for durable and reliable connections in various applications. Among the various types of welding electrodes available, the J422 welding electrode has emerged as a vital component in the fabrication and repair sectors. This article delves into the characteristics of J422 welding electrodes, the types of factories that manufacture them, and their pervasive implications in the manufacturing industry.

Understanding J422 Welding Electrodes

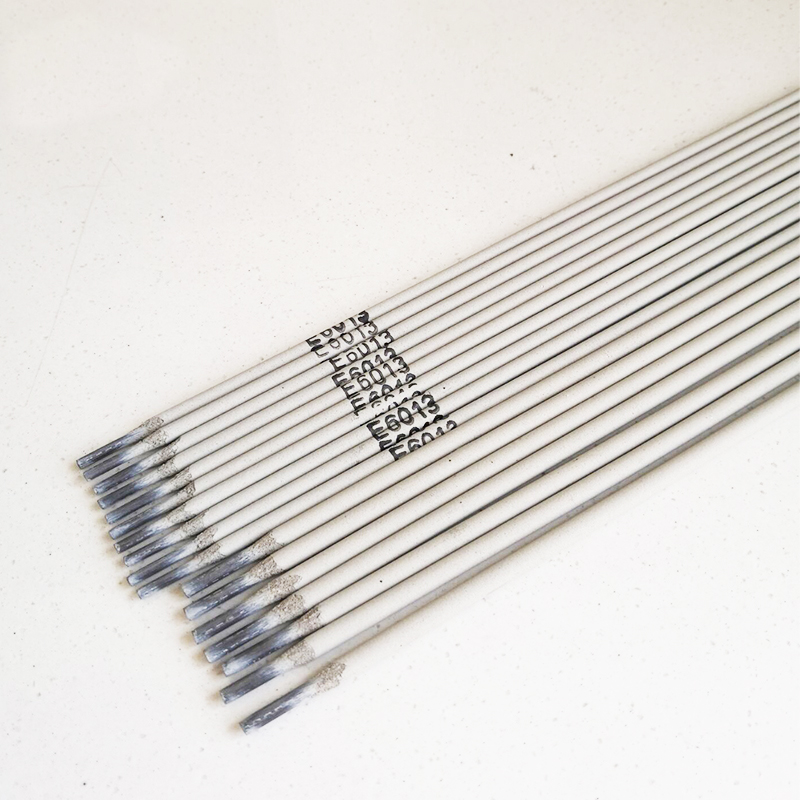

J422 welding electrodes are primarily used for shielded metal arc welding (SMAW), a process preferred for its simplicity and effectiveness. These electrodes are characterized by their potassium-based coating, which improves arc stability, provides excellent slag removal, and contributes to a smoother finish on welded joints. They are known for their versatility and are suitable for welding low-alloy steels, carbon steels, and even some stainless steels, making them a go-to choice in many industrial applications.

One of the unique selling points of J422 electrodes is their ability to withstand harsh welding conditions. They are especially effective in situations where the welding process is subjected to varying temperatures and humidity levels. The electrodes perform excellently across different positions, whether it is flat, horizontal, vertical, or overhead welding. This adaptability is crucial for manufacturers aiming to maintain high-quality standards in a competitive market.

The Role of J422 Welding Electrode Factories

The production of J422 welding electrodes is carried out in specialized factories equipped with advanced technology. These factories follow stringent quality control measures to ensure that the electrodes produced meet international standards. The manufacturing process involves several key stages, including raw material sourcing, coating application, and packaging.

The raw materials typically include high-quality steel wire and a specially formulated coating that imparts specific properties to the electrodes. The coating process is critical, as it influences the electrode's performance during welding. Factories employ automated machinery to coat the wire uniformly, ensuring that each electrode has consistent characteristics.

j422 welding electrodes factories

In addition to the production process, J422 welding electrode factories also focus on research and development. They continually seek ways to improve the performance of their products, focusing on enhancing their efficiency, durability, and cost-effectiveness. The evolution of technology in the welding industry calls for constant innovation, and many factories collaborate with research institutions to stay ahead of the competition.

Environmental Considerations

As environmental concerns grow worldwide, welding electrode factories are increasingly adopting sustainable practices in production. This includes minimizing waste, utilizing eco-friendly materials, and reducing emissions during manufacturing. Many factories are incorporating recycling processes to reclaim materials, further supporting a circular economy.

By prioritizing sustainability, these factories not only contribute to reducing their carbon footprint but also enhance their brand reputation. Clients are more likely to partner with manufacturers that demonstrate environmental responsibility, leading to increased market opportunities.

Conclusion

J422 welding electrodes serve as a cornerstone in the welding industry, providing essential solutions for a range of applications from construction to automotive manufacturing. The factories that produce these electrodes play a significant role in ensuring the quality and reliability of the welding process. As the industry continues to evolve, the importance of innovative manufacturing practices and sustainable approaches will only grow.

In conclusion, the significance of J422 welding electrodes extends beyond their technical attributes; they are vital to the resilience and efficiency of the manufacturing sector. The ongoing commitment to quality, research, and sustainability in electrode production will undoubtedly shape the future of welding, empowering industries to meet the demands of an ever-changing world. As manufacturers and researchers collaborate to perfect these welding solutions, the impact of J422 welding electrodes will undoubtedly resonate for years to come, reinforcing their position as a key player in the global manufacturing landscape.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025