Jun . 27, 2024 03:40

Back to list

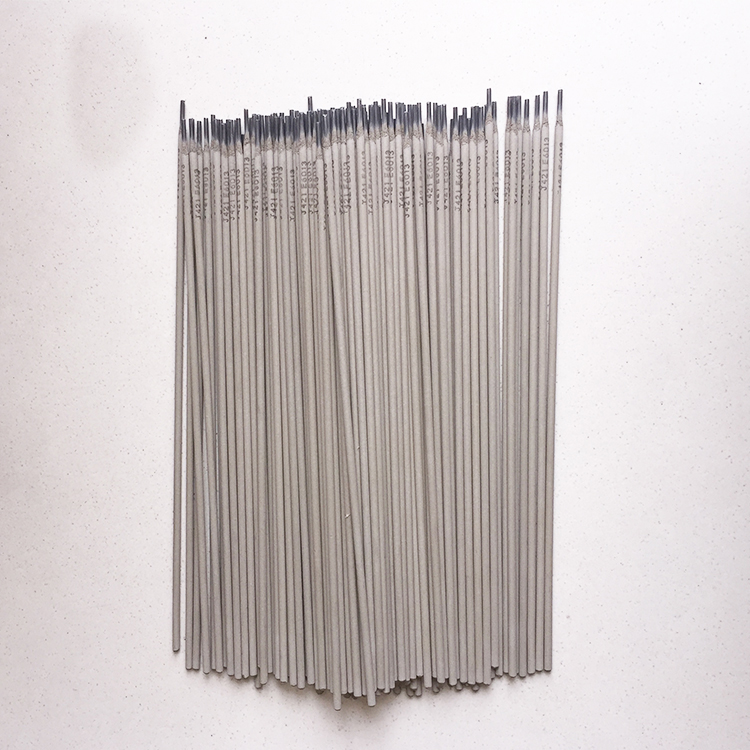

Leading Chinese Manufacturer of E6013 Welding Electrodes for Superior Performance

China E6013 Welding Electrodes A Comprehensive Overview of Key Manufacturers

In the global welding industry, China has emerged as a significant player, particularly in the manufacturing of E6013 welding electrodes. These electrodes, known for their all-position welding capabilities and excellent arc stability, are widely used in various applications ranging from construction to automotive repairs. The Chinese market, with its robust manufacturing base and cost-effectiveness, has become a major supplier to international markets.

Key manufacturers in China have been instrumental in driving the growth of E6013 welding electrodes. Companies like Shanghai Baosteel Welding Material Co., Ltd., Tianjin Bridge Welding Materials Group Co., Ltd., and Zhejiang Huayi Welding Material Co., Ltd., among others, have established themselves as leading players in this sector. They boast advanced production facilities, stringent quality control measures, and a commitment to innovation, ensuring that their products meet international standards.

Shanghai Baosteel Welding Material, for instance, is renowned for its high-quality E6013 electrodes, offering superior welding performance and excellent bead appearance

Shanghai Baosteel Welding Material, for instance, is renowned for its high-quality E6013 electrodes, offering superior welding performance and excellent bead appearance Shanghai Baosteel Welding Material, for instance, is renowned for its high-quality E6013 electrodes, offering superior welding performance and excellent bead appearance

Shanghai Baosteel Welding Material, for instance, is renowned for its high-quality E6013 electrodes, offering superior welding performance and excellent bead appearance

Shanghai Baosteel Welding Material, for instance, is renowned for its high-quality E6013 electrodes, offering superior welding performance and excellent bead appearance

Shanghai Baosteel Welding Material, for instance, is renowned for its high-quality E6013 electrodes, offering superior welding performance and excellent bead appearance china e6013 welding electrodes manufacturer. Their electrodes are designed to provide minimal spatter, easy slag removal, and good penetration, making them ideal for both manual and automatic welding processes.

Tianjin Bridge Welding Materials, another prominent manufacturer, specializes in a wide range of welding consumables, including the E6013 electrodes. Their products are known for their consistent performance, durability, and resistance to hydrogen cracking, catering to diverse welding needs across different industries.

Zhejiang Huayi Welding Material, on the other hand, focuses on sustainable manufacturing practices while maintaining product excellence. Their E6013 electrodes are eco-friendly, with low hydrogen content, ensuring safety during welding operations and reducing environmental impact.

Chinese manufacturers have not only mastered the mass production of E6013 electrodes but also continually invest in research and development to improve their offerings. They strive to enhance electrode efficiency, reduce welding defects, and cater to the evolving demands of the welding industry. This dedication to innovation has made Chinese E6013 welding electrodes highly competitive in the global market.

In conclusion, China's E6013 welding electrodes manufacturers have carved a niche for themselves in the welding world. With their commitment to quality, innovation, and competitive pricing, these companies have become crucial suppliers, serving a global customer base. As the welding industry continues to evolve, it is expected that Chinese manufacturers will maintain their position at the forefront, shaping the future of welding technology.

china e6013 welding electrodes manufacturer. Their electrodes are designed to provide minimal spatter, easy slag removal, and good penetration, making them ideal for both manual and automatic welding processes.

Tianjin Bridge Welding Materials, another prominent manufacturer, specializes in a wide range of welding consumables, including the E6013 electrodes. Their products are known for their consistent performance, durability, and resistance to hydrogen cracking, catering to diverse welding needs across different industries.

Zhejiang Huayi Welding Material, on the other hand, focuses on sustainable manufacturing practices while maintaining product excellence. Their E6013 electrodes are eco-friendly, with low hydrogen content, ensuring safety during welding operations and reducing environmental impact.

Chinese manufacturers have not only mastered the mass production of E6013 electrodes but also continually invest in research and development to improve their offerings. They strive to enhance electrode efficiency, reduce welding defects, and cater to the evolving demands of the welding industry. This dedication to innovation has made Chinese E6013 welding electrodes highly competitive in the global market.

In conclusion, China's E6013 welding electrodes manufacturers have carved a niche for themselves in the welding world. With their commitment to quality, innovation, and competitive pricing, these companies have become crucial suppliers, serving a global customer base. As the welding industry continues to evolve, it is expected that Chinese manufacturers will maintain their position at the forefront, shaping the future of welding technology.

Shanghai Baosteel Welding Material, for instance, is renowned for its high-quality E6013 electrodes, offering superior welding performance and excellent bead appearance

Shanghai Baosteel Welding Material, for instance, is renowned for its high-quality E6013 electrodes, offering superior welding performance and excellent bead appearance

Shanghai Baosteel Welding Material, for instance, is renowned for its high-quality E6013 electrodes, offering superior welding performance and excellent bead appearance

Shanghai Baosteel Welding Material, for instance, is renowned for its high-quality E6013 electrodes, offering superior welding performance and excellent bead appearance china e6013 welding electrodes manufacturer. Their electrodes are designed to provide minimal spatter, easy slag removal, and good penetration, making them ideal for both manual and automatic welding processes.

Tianjin Bridge Welding Materials, another prominent manufacturer, specializes in a wide range of welding consumables, including the E6013 electrodes. Their products are known for their consistent performance, durability, and resistance to hydrogen cracking, catering to diverse welding needs across different industries.

Zhejiang Huayi Welding Material, on the other hand, focuses on sustainable manufacturing practices while maintaining product excellence. Their E6013 electrodes are eco-friendly, with low hydrogen content, ensuring safety during welding operations and reducing environmental impact.

Chinese manufacturers have not only mastered the mass production of E6013 electrodes but also continually invest in research and development to improve their offerings. They strive to enhance electrode efficiency, reduce welding defects, and cater to the evolving demands of the welding industry. This dedication to innovation has made Chinese E6013 welding electrodes highly competitive in the global market.

In conclusion, China's E6013 welding electrodes manufacturers have carved a niche for themselves in the welding world. With their commitment to quality, innovation, and competitive pricing, these companies have become crucial suppliers, serving a global customer base. As the welding industry continues to evolve, it is expected that Chinese manufacturers will maintain their position at the forefront, shaping the future of welding technology.

china e6013 welding electrodes manufacturer. Their electrodes are designed to provide minimal spatter, easy slag removal, and good penetration, making them ideal for both manual and automatic welding processes.

Tianjin Bridge Welding Materials, another prominent manufacturer, specializes in a wide range of welding consumables, including the E6013 electrodes. Their products are known for their consistent performance, durability, and resistance to hydrogen cracking, catering to diverse welding needs across different industries.

Zhejiang Huayi Welding Material, on the other hand, focuses on sustainable manufacturing practices while maintaining product excellence. Their E6013 electrodes are eco-friendly, with low hydrogen content, ensuring safety during welding operations and reducing environmental impact.

Chinese manufacturers have not only mastered the mass production of E6013 electrodes but also continually invest in research and development to improve their offerings. They strive to enhance electrode efficiency, reduce welding defects, and cater to the evolving demands of the welding industry. This dedication to innovation has made Chinese E6013 welding electrodes highly competitive in the global market.

In conclusion, China's E6013 welding electrodes manufacturers have carved a niche for themselves in the welding world. With their commitment to quality, innovation, and competitive pricing, these companies have become crucial suppliers, serving a global customer base. As the welding industry continues to evolve, it is expected that Chinese manufacturers will maintain their position at the forefront, shaping the future of welding technology. Latest news

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025