Leading Manufacturer of High-Quality 7018 Welding Electrodes in China for Excellent Performance

The Rise of 7018 Welding Electrodes A Focus on China’s Manufacturers

Welding plays an essential role in various industries, including construction, manufacturing, and automotive. Among the different types of welding electrodes, the E7018 is highly regarded for its excellent mechanical properties and ease of use. As demand for quality welding materials continues to grow, manufacturers in China have emerged as key players in the global market for E7018 welding electrodes.

Understanding E7018 Welding Electrodes

E7018 electrodes are covered with a low-hydrogen flux, which contributes to the overall strength and ductility of the weld. This characteristic makes them particularly suitable for welding structural steel and high-strength materials. The E stands for electrode, while “70” indicates the minimum yield strength of 70,000 psi. The “18” represents the type of coating and the position of welding, allowing for versatility in applications.

These electrodes are widely used in critical construction projects, where weld integrity is paramount. Their low-hydrogen properties minimize the risk of hydrogen-induced cracking, making them ideal for heavy-duty applications like bridge construction, shipbuilding, and pipeline installation.

The Chinese Manufacturing Landscape

China has become a hub for the production of welding materials, including E7018 electrodes. The country's extensive manufacturing infrastructure, combined with an increase in technological advancements, has enabled Chinese manufacturers to produce high-quality welding rods that meet international standards.

Chinese manufacturers benefit from a broad supply chain network, allowing for quick procurement of raw materials and distribution of finished products. The availability of skilled labor and expertise in welding technology has further cemented the country’s position as a leader in this sector. Many manufacturers have invested in research and development to improve the formulations and consistency of their electrodes, ensuring they can hold their own in the competitive global market.

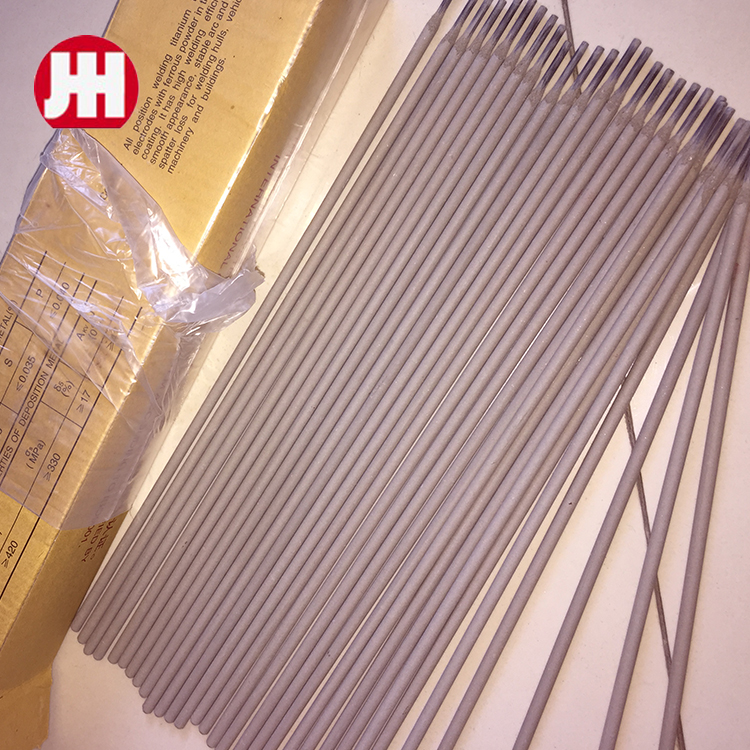

china welding electrode 7018 manufacturer

Quality Assurance

Quality control is paramount in the production of E7018 welding electrodes. Leading Chinese manufacturers adhere to strict quality assurance protocols, employing both automated and manual inspection processes to ensure each batch meets the required specifications. Certificates of compliance and third-party testing are often provided to reassure customers that the products are reliable and safe for use in critical applications.

Moreover, several Chinese manufacturers have sought certifications from international bodies, such as the American Welding Society (AWS) and ISO, to enhance their credibility and trustworthiness. This dedication to quality has allowed them to penetrate not only domestic markets but also to export their products worldwide.

Sustainability and Future Prospects

With the increasing global focus on sustainability, many Chinese manufacturers are also exploring eco-friendly production methods. Efforts are being made to minimize waste, reduce emissions, and incorporate sustainable materials in the production of E7018 electrodes. As countries implement stricter environmental regulations, the ability to produce sustainable welding materials will offer a competitive edge.

The outlook for China’s E7018 welding electrode manufacturers is promising. As global demand for construction and infrastructure development continues to rise, these manufacturers are well-positioned to meet the needs of both domestic and international markets. By investing in technology, enhancing quality control, and adopting sustainable practices, they can maintain their competitive advantage and continue to lead the industry.

Conclusion

The growth of E7018 welding electrode manufacturing in China represents a significant development in the global welding industry. With a strong focus on quality, innovation, and sustainability, Chinese manufacturers have established themselves as leaders in this critical market. As industries evolve and adapt to new challenges, the role of welding, particularly through the use of quality electrodes like the E7018, will remain indispensable, making China a pivotal player in this domain.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025