Leading Manufacturers of CO2 MIG MAG Welding Wire for High-Quality Welding Solutions in Industry

The Evolution of CO2 MIG MAG Welding Wire Manufacturers

In the realm of modern welding technology, the significance of CO2 MIG (Metal Inert Gas) and MAG (Metal Active Gas) welding processes cannot be understated. As industries strive for efficiency, precision, and cost-effectiveness, the demand for high-quality welding wires has surged. This article delves into the role of CO2 MIG MAG welding wire manufacturers, their innovations, and their impact on various sectors.

Understanding CO2 MIG MAG Welding

CO2 welding is a variant of MIG welding that utilizes carbon dioxide as a shielding gas to protect the weld from atmospheric contamination. This process is particularly advantageous for its ability to weld various materials, including steel and stainless steel, with high precision and speed. The MIG and MAG processes differ primarily in their choice of shielding gas; while MIG typically employs inert gases like argon, MAG uses active gases such as carbon dioxide and oxygen.

The Role of Manufacturers

CO2 MIG MAG welding wire manufacturers are at the forefront of this process, providing essential materials that enable high-quality welds. These manufacturers not only produce wires but also improve their properties to meet the diverse needs of different industries. For instance, they focus on creating wires that offer minimal spatter, excellent arc stability, and superior bead appearance.

The manufacturing process itself involves stringent quality control measures. This ensures that every batch of welding wire maintains consistent chemical composition, diameter, and tensile strength. Leading manufacturers utilize advanced technologies and materials, such as alloying elements, to enhance the performance of their welding wires. By doing so, they contribute to the overall efficiency and reliability of the welding process.

Innovations in Welding Wire Technology

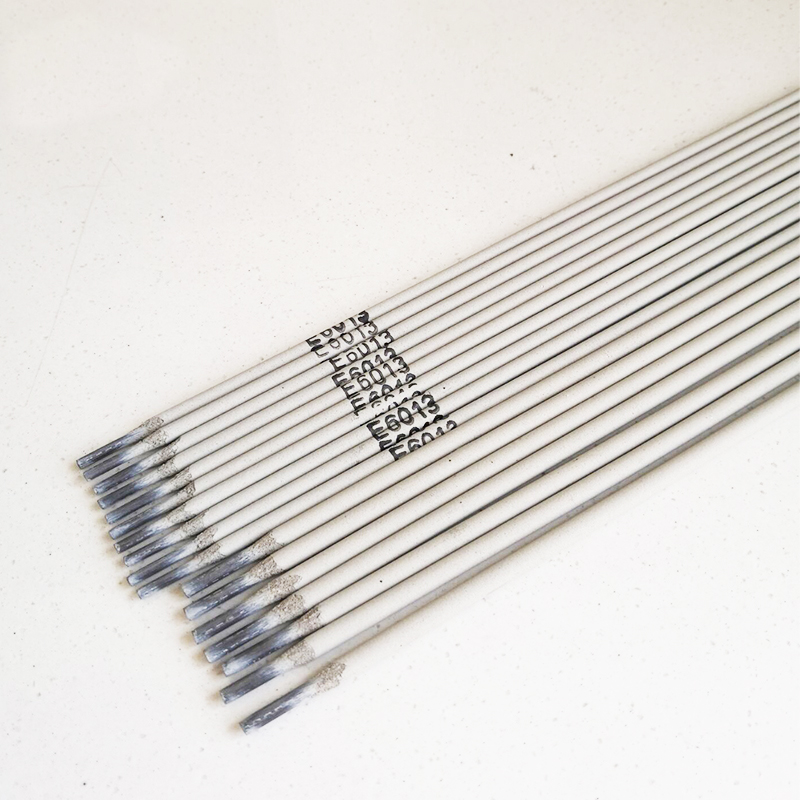

co2 mig mag welding wire manufacturer

One of the significant advancements in CO2 MIG MAG welding wire technology is the development of low-spatter wires. These wires are engineered to produce less spatter during the welding process, which not only results in cleaner welds but also minimizes post-weld cleanup time. Additionally, low-spatter wires improve the lifespan of welding tips and contact tips, resulting in cost savings for manufacturers and welders alike.

Another innovation is the production of multi-purpose welding wires that can be used across different applications. These versatile wires reduce the need for multiple wire types, simplifying inventory management for businesses and minimizing training time for operators.

Furthermore, some manufacturers are exploring eco-friendly options, such as wires that produce fewer fumes and lower emissions during welding. This shift towards sustainability resonates with global trends focused on reducing environmental impact across all industries.

Industry Applications

The applications of CO2 MIG MAG welding wires span a wide range of industries, including automotive, construction, shipbuilding, and manufacturing. In the automotive sector, for instance, precision welding is crucial for the safety and durability of vehicles. Manufacturers supply specialized wires that cater specifically to the demands of this industry, ensuring that welds meet stringent safety standards.

In construction, the strength and reliability of welds are paramount. High-quality CO2 MIG MAG welding wires ensure that structural elements can withstand various stressors. Similarly, in shipbuilding, where materials may be exposed to harsh marine conditions, manufacturers provide wires that are resistant to corrosion and wear.

Conclusion

As industries continue to evolve, the role of CO2 MIG MAG welding wire manufacturers remains critical. Their advancements in technology, commitment to quality, and responsiveness to market demands ensure that welding processes are more efficient and sustainable. By supplying innovative welding wires that meet the ever-changing needs of different sectors, these manufacturers are not only enhancing welding outcomes but also contributing to the overall progress of industrial manufacturing. The future of welding wire production looks promising, driven by innovation and a commitment to excellence.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025