Manufacturers of 316L Welding Electrodes for High-Quality Stainless Steel Fabrication and Applications

Understanding 316L Welding Electrode Factories

Welding electrodes play a pivotal role in the fabrication of stainless steel components, particularly when dealing with materials like 316L stainless steel, known for its excellent corrosion resistance and strength. The manufacturing of 316L welding electrodes is a specialized field within the larger welding supply industry, with numerous factories dedicated to producing these essential components for the welding process.

What is 316L Stainless Steel?

Before delving into the factories that produce 316L welding electrodes, it is crucial to understand what 316L stainless steel is. 316L is an alloy primarily composed of iron, with significant amounts of nickel and molybdenum, which enhance its resistance to corrosion, especially in chloride environments. Its low carbon content (denoted by the L in 316L) contributes to improved weldability and lower susceptibility to carbide precipitation, making it ideal for various applications, including chemical processing, medical devices, and marine environments.

The Role of Welding Electrodes

Welding electrodes are rods or wires used to carry current into a welding arc. They melt to provide filler material to the weld joint. In the case of 316L welding electrodes, they contain similar alloy compositions to 316L stainless steel, ensuring compatibility and strength in welds. Factories that produce these electrodes must adhere to strict quality control standards to ensure the electrodes produce strong, corrosion-resistant welds.

Manufacturing Process

The production of 316L welding electrodes involves multiple steps. First, raw materials such as stainless steel powders and additives are sourced. These materials are then carefully blended to create a uniform composition that meets the required specifications for 316L electrodes. The mixture is subjected to processes such as extrusion or drawing to form the electrode's core.

316l welding electrode factories

After the core is formed, it is coated with a protective layer that enhances its performance during welding. This coating, often comprising various minerals and chemicals, helps stabilize the arc and improves the quality of the weld. Once coated, the electrodes undergo heat treatment to enhance their mechanical properties. Finally, the electrodes are tested rigorously for performance and quality assurance before being packaged for shipment.

Quality Assurance in Factories

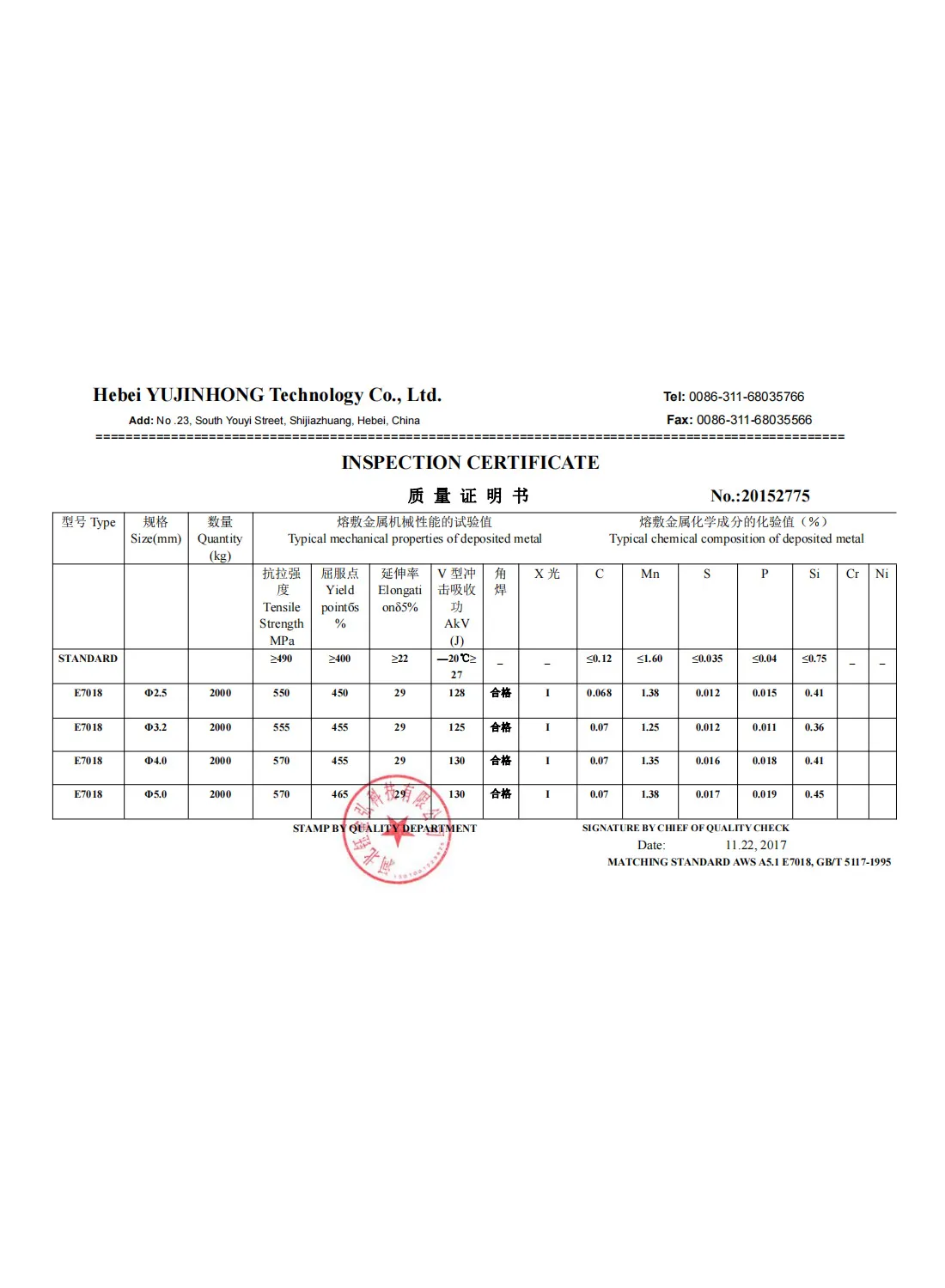

Quality assurance is a critical aspect of 316L welding electrode factories. These facilities typically implement extensive testing protocols, including chemical analysis, tensile testing, and arc performance testing, to ensure that every electrode produced meets industry standards. Adhering to international standards, such as those set by the American Welding Society (AWS) and the International Organization for Standardization (ISO), is vital for maintaining the credibility and reliability of the products.

The Global Market for 316L Welding Electrodes

The demand for 316L welding electrodes has been growing, driven by the expanding industries requiring high-performance materials. Regions such as North America, Europe, and Asia-Pacific are significant consumers due to their thriving manufacturing and construction sectors. Consequently, manufacturing factories are not only based in countries with a rich tradition of metallurgy, like Germany and Italy, but also in emerging economies looking to strengthen their industrial capabilities.

Conclusion

In summary, 316L welding electrode factories are essential players in the manufacturing and fabrication industries, ensuring high-quality welding materials are available for a myriad of applications. Their focus on stringent quality control and adherence to international standards enables them to meet the specific needs of industries where reliability and performance are paramount. As industries continue to evolve, so too will the technology and processes behind the production of 316L welding electrodes, further enhancing their significance in modern manufacturing.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025