MIG Welding vs. Stick Welding

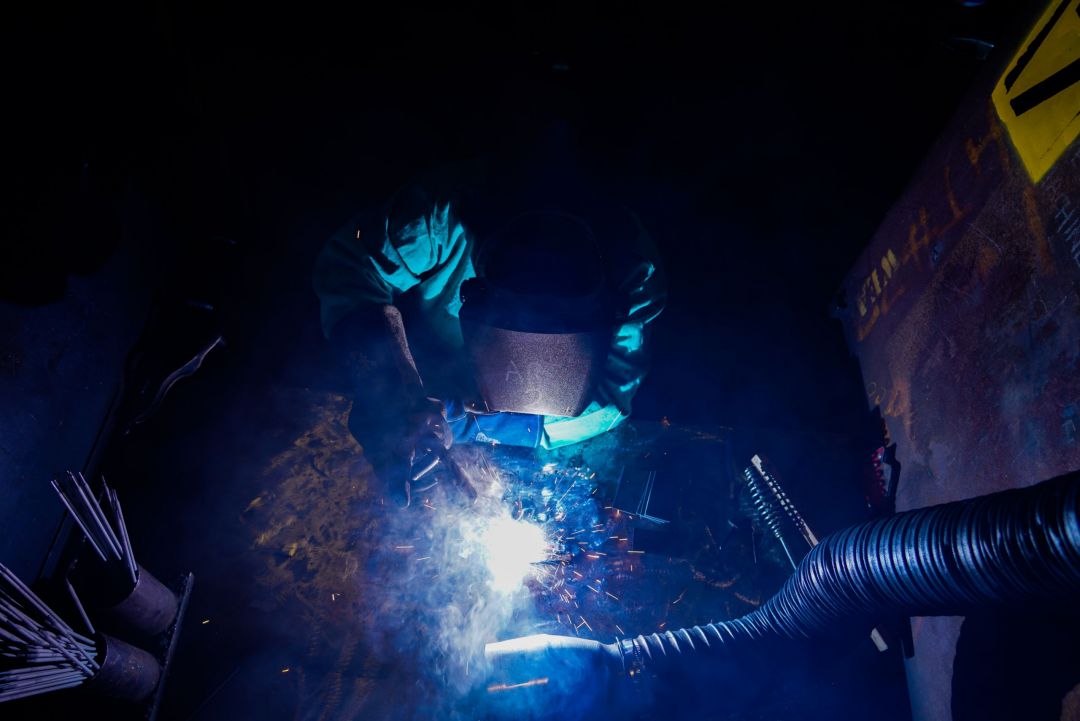

MIG (also called Gas Metal Arc Welding, or GMAW) and stick (Shielded Metal Arc Welding, or SMAW) welding are two of the most commonly used arc welding processes, along with TIG. And although they share some similarities, one can produce much better results than the other for certain applications.

What’s The Difference Between MIG And Stick Welding?

Although MIG and Stick welding can both produce a quality weld, their setups, pros, cons and applications are quite different. Generally speaking, MIG welding is the easiest form of welding to learn, and the easiest torch to operate. And while Stick welding can also be a quick study, it’s more difficult to master. Stick is the oldest form of arc welding — around since the 30s — and is still considered the only choice for many veteran welders.

QUALITY And QUANTITY

Both MIG and Stick welding systems can produce high-quality welds, but the type of metal makes a big difference in which machine works better. For thinner metals, MIG welding is the better choice for creating a clean, strong joint. On thicker metals — over ⅜ inch — the Stick has better performance.

The MIG gun’s ease of use also means it can produce a great volume of work with little downtime. For that reason, it’s often used in fabrication and is also the choice for robotic welding operations. Stick welding takes longer, including a warm-up period when first turning on the gun and the more frequent downtime that comes with changing out electrodes.

{{cta(‘f4fb650b-2702-44e1-ba90-cd7b49a186bb’)}}

CLEANLINESS

The MIG and Stick welders have opposite pros and cons when it comes to cleanliness and cleanup, with one requiring more work upfront and the other post-weld. Because a Stick welder can form a strong joint on even an unclean or rusty surface, the pre-weld prep of cleaning the workpiece that’s required with a MIG setup isn’t necessary.

However, the electrodes used in Stick welding are covered with flux, which creates spatter during the weld that must be chipped off after it cools. With MIG, however, the shielding gas not only protects the weld as it cools, but also blows away any spatter. The end result is a lot less cleanup.

VERSATILITY

One of the biggest advantages of Stick over MIG is its ability to weld outside, in windy conditions, or anywhere that the MIG setup’s shielding gas would be compromised. In fact, it can be wheeled to wherever you need it, where the MIG welder is bound by the length of its cable. Another advantage of a Stick welder is the ability to change the angle of the nozzle in order to weld in tight corners or obtuse angles.

MAINTENANCE AND COST

Stick welding is considered one of the most inexpensive forms of welding, while MIG welding tends to cost more due to its high number of consumables (and downtime required to change them.) That cost may be somewhat offset, however, by the long welds that are possible because of the MIG gun’s continuously feeding wire. Even though a stick welder doesn’t use consumables other than the electrode, a weld can only last as long as the length of the stick before it needs to be replaced.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025