mig flux core welding wire factory

Understanding MIG Flux Core Welding Wire Factories

MIG (Metal Inert Gas) welding, an essential process in various manufacturing sectors, encompasses a variety of techniques and materials, one of which is flux core welding wire. The production of flux core welding wire is a nuanced process that requires precision and expertise, often carried out in specialized factories dedicated to producing high-quality welding material.

What is MIG Flux Core Welding?

Before delving into the factories that produce flux core welding wire, it’s important to understand what MIG flux core welding entails. Unlike traditional MIG welding that uses a solid wire and an inert gas shielding, flux core welding employs a tubular wire filled with flux. This design allows for a continuous and versatile welding process, particularly effective in outdoor environments and in situations where wind might disperse shielding gases.

Flux core welding wire ignites and uses its inner flux to produce a shielding gas as it melts, which protects the weld from contaminants like oxygen and moisture. This process is advantageous for its ability to deliver strong welds on thicker materials and its versatility across various metals, including steel, stainless steel, and aluminum.

The Role of Factories in Wire Production

The manufacturing of MIG flux core welding wire takes place in specialized factories equipped with advanced machinery and technology. These factories focus on several core aspects of production

1. Material Selection The first step in the production of flux core welding wire is selecting the appropriate raw materials. The wire itself typically consists of a mild steel or stainless steel substrate, while the flux is composed of a blend of chemicals designed to improve weld quality, stability, and penetration.

2. Wire Drawing After selecting materials, the solid metal wire undergoes a wire drawing process, which reduces its diameter to the desired size. This stage plays a crucial role in ensuring that the wire can feed smoothly through welding machines.

mig flux core welding wire factory

3. Filling with Flux The flux core is then filled into the hollow wire. This stage is critical; maintaining the correct percentage of flux is essential to ensure optimal performance. The quality of the flux composition directly influences the weld’s integrity, electrical conductivity, and overall ease of use.

4. Welding Process Simulation Modern factories often use welding simulations to test the performance of their flux core wire. These simulations assess the wire’s performance under various conditions, ensuring that it meets industry standards before it reaches the market.

5. Quality Control Given the importance of reliability in welding operations, stringent quality control measures are a vital part of the production process. Factories frequently conduct tests on finished products, evaluating factors such as tensile strength, flexibility, and the overall consistency of the wire.

Advances in Flux Core Wire Manufacturing

In recent years, there have been numerous advancements in the manufacturing processes for flux core welding wire. Automation has played a significant role in enhancing production efficiency, reducing waste, and improving the accuracy of wire dimensions.

Moreover, environmental sustainability has become a focal point, with factories increasingly adopting eco-friendly practices in their operations. This includes responsible sourcing of materials and recycling of unused welding wire.

Conclusion

The production of MIG flux core welding wire is a complex process that blends science and craftsmanship. By understanding the operations within specialized factories, one gains appreciation for the quality and reliability that goes into every spool of welding wire. The advancements in technology and manufacturing processes promise to improve this vital industry even further, ensuring that welders have access to high-performing materials that meet their diverse needs. As industries continue to evolve with technological advancements, the significance of quality production in welding supplies will undoubtedly remain pivotal.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

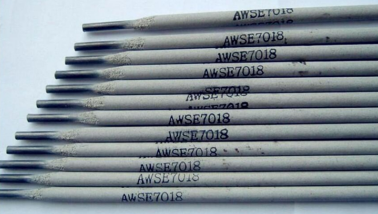

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025