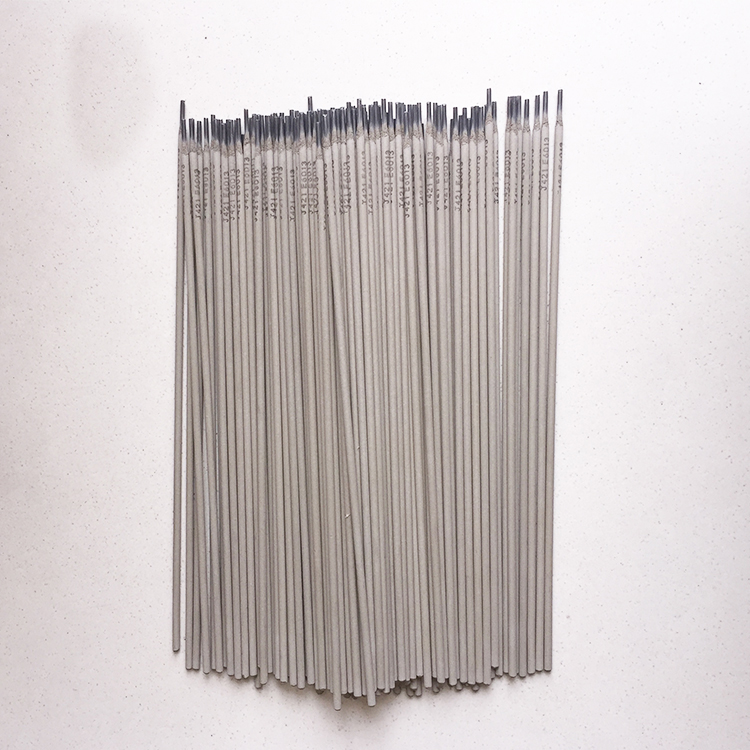

mig welding electrode supplier

The Importance of Choosing the Right MIG Welding Electrode Supplier

MIG (Metal Inert Gas) welding is a widely used welding process known for its speed and efficiency. It utilizes a continuous feed of filler metal through a welding gun, which melts and fills the joint between two pieces of metal. The quality and performance of a MIG welding project significantly depend on the choice of welding electrodes and, more importantly, the supplier from whom these electrodes are procured. This article aims to discuss the importance of choosing the right MIG welding electrode supplier and the factors to consider in this process.

Quality Assurance

One of the primary reasons for selecting a reputable MIG welding electrode supplier is quality assurance. High-quality electrodes are crucial for achieving strong, durable welds. Reputable suppliers often adhere to strict manufacturing standards, ensuring that their electrodes meet industry specifications. They typically conduct rigorous testing to verify the quality of their products, including tensile strength, elongation, and impact resistance. By choosing a supplier known for their high-quality offerings, welders can ensure optimal performance in their welding operations.

Range of Products

Another important factor to consider when selecting a MIG welding electrode supplier is the range of products available. Different welding applications may require specific types of electrodes based on the materials being welded and the desired characteristics of the weld. A reliable supplier should offer a comprehensive selection of MIG electrodes, including those made for aluminum, stainless steel, and carbon steel. Additionally, accessories like gas nozzles, contact tips, and liners should also be part of their inventory. A supplier that can meet the diverse needs of various welding projects saves time and effort, allowing welders to find the appropriate products in one place.

Expertise and Support

A knowledgeable supplier can be an invaluable resource for welders. Many established suppliers have a team of welding experts who can provide advice on electrode selection, welding techniques, and troubleshooting. This level of support is especially beneficial for novice welders or those tackling unique projects. By collaborating with a supplier who has deep expertise in MIG welding, customers can benefit from personalized recommendations and guidance that can enhance their welding outcomes.

mig welding electrode supplier

Pricing and Value

While price is often a crucial consideration, it should not be the only factor influencing the choice of a MIG welding electrode supplier. It's essential to evaluate the overall value offered by the supplier rather than simply opting for the lowest price. Factors such as product quality, customer service, and technical support should also weigh heavily in this decision. An economical option that compromises on quality could lead to defective welds and increased costs in the long run due to repairs or rework. Therefore, a balance between cost and quality should be sought when selecting a supplier.

Convenience and Delivery

In today's fast-paced manufacturing environment, timely delivery of products can be critical. Suppliers that can provide quick and reliable shipping options are preferable, especially for businesses that rely on a steady supply of MIG welding electrodes to meet project deadlines. Furthermore, suppliers that offer online ordering and inventory tracking add an extra layer of convenience, simplifying the procurement process for customers.

Reputation and Reviews

Finally, it is essential to consider the supplier's reputation in the industry. Researching reviews and testimonials from previous customers can provide insight into the supplier’s reliability and service quality. Engaging with other welders or professionals in the field can also yield valuable recommendations. A supplier with a strong track record of customer satisfaction is likely to be a safe choice.

Conclusion

Selecting the right MIG welding electrode supplier is a critical decision that can significantly impact the quality and efficiency of welding projects. By considering factors such as product quality, range, expertise, pricing, delivery options, and the supplier’s reputation, welders can make informed decisions that will lead to successful outcomes. Investing time in choosing a reputable supplier will ultimately foster a smoother welding experience, resulting in stronger and more reliable welds. Whether you’re a seasoned expert or a novice welder, the choice of a MIG welding electrode supplier is a foundational element of successful welding operations.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025