pipe welding stick factory

The Importance of Pipe Welding in the Manufacturing Sector

When it comes to the manufacturing of industrial components, the role of pipe welding cannot be understated. Factories around the world depend on efficient welding techniques to create strong, durable connections between pipes, ensuring that systems function properly across various applications. Among these techniques, stick welding, also known as Shielded Metal Arc Welding (SMAW), has established itself as a reliable method in the production of pipe assemblies.

Understanding Stick Welding

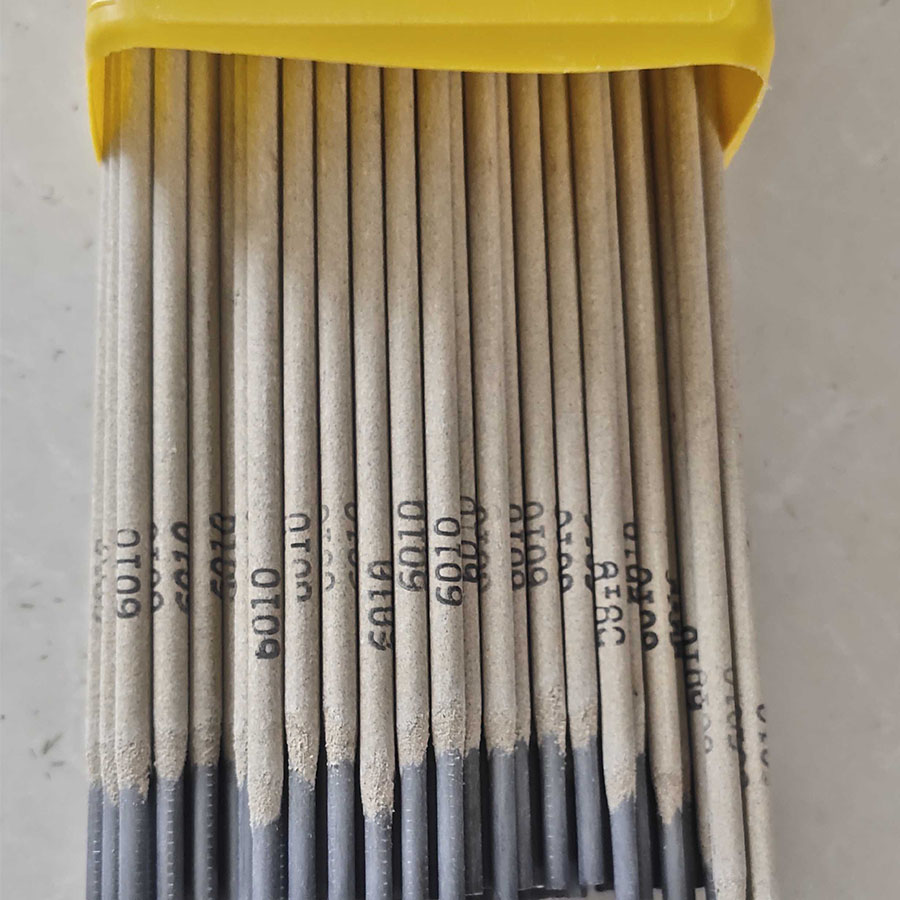

Stick welding is a process that involves the use of an electrode coated with a flux material. As the electrode melts during the welding process, the flux creates a protective gas, which prevents contamination from atmospheric factors. This distinct advantage allows stick welding to be deployed in a range of environments, including those with limited access to advanced equipment. In pipe manufacturing, stick welding is particularly favored for its versatility and effectiveness in joining thick materials.

The Process of Pipe Welding

The pipe welding process begins with the careful preparation of the pipe joints. Proper alignment and cleaning are crucial steps to prevent impurities from compromising the weld. Once the pipes are positioned, the welder uses a stick electrode to create an electric arc between the electrode and the base metal. This arc generates intense heat, melting the surface of the pipe and the electrode simultaneously. As the molten metal cools, it solidifies to form a strong bond.

Applications in Various Industries

Pipe welding is an essential part of many different sectors, including oil and gas, manufacturing, construction, and water treatment. In the oil and gas industry, for instance, pipelines are exposed to extreme conditions, making the integrity of the welds critical. A compromised weld can lead to leaks, which pose environmental hazards and financial losses. Therefore, the proficiency of welders in using stick welding techniques is vital for ensuring the reliability of such infrastructures.

In construction, pipe systems are employed for various purposes, including HVAC, drainage, and plumbing. The flexibility of stick welding allows for quick repairs and modifications, which is particularly advantageous in dynamic construction environments where plans may change frequently.

pipe welding stick factory

Advantages of Stick Welding in Pipe Fabrication

One of the key benefits of stick welding in the context of pipe fabrication is its portability. The equipment required for stick welding is relatively lightweight and compact, allowing welders to operate in remote locations or even on-site, without the need for extensive setups. Additionally, the process is relatively simple to master, making it accessible for new welders while also being a trusted method for seasoned professionals.

Moreover, stick welding is less sensitive to factors like wind and moisture compared to other welding techniques, making it an ideal choice for outdoor projects. This resilience means that projects can continue regardless of weather conditions, enhancing productivity and reducing downtime.

Challenges and Considerations

Despite its many advantages, stick welding does come with its share of challenges. The process can be slower compared to other methods like MIG or TIG welding, especially when working with thicker materials. Welders also need to maintain a steady hand and proper technique to prevent defects in the welds, such as slag inclusions or incomplete fusion.

Furthermore, the choice of electrode type is crucial for achieving optimal results. Different materials and thicknesses require specific electrodes to ensure the strength and quality of the weld. Therefore, companies engaging in pipe welding must invest in training for their staff, alongside maintaining an inventory of various electrodes tailored to their operational needs.

Conclusion

As the demand for durable and efficient industrial pipelines continues to grow, the significance of pipe welding—particularly via stick welding—will remain vital in the manufacturing sector. With its unique advantages and applications across numerous industries, stick welding continues to uphold its reputation as a reliable method for creating strong, long-lasting pipe assemblies. As technology progresses, the industry will undoubtedly evolve, but the foundational skills and techniques of welders will remain critical to ensuring the success of this essential trade.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025