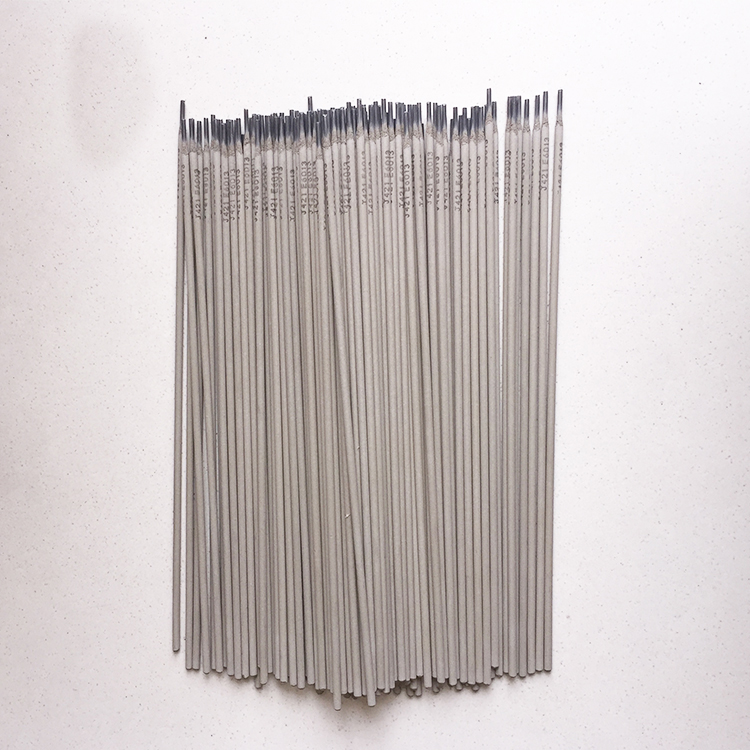

Premium Carbon Rods for Welding: Durable & Efficient Welds

Understanding Carbon Rods for Welding: An Essential Guide for B2B Professionals

In the demanding world of industrial fabrication and repair, the selection of appropriate welding consumables is paramount to achieving structural integrity and operational longevity. Among these, carbon rods for welding, often referred to as carbon steel welding electrodes or carbon sticks for welding, play a critical role, particularly in arc welding applications. These specialized electrodes are engineered to provide exceptional performance when joining carbon steel components, offering a balance of strength, ductility, and ease of use. This comprehensive guide delves into the technical intricacies, manufacturing excellence, diverse applications, and strategic advantages associated with these vital welding tools, tailored for B2B decision-makers and engineering teams seeking robust and reliable solutions.

Manufacturing Process: The Genesis of High-Performance Welding Electrodes

The production of high-quality carbon rods for welding is a meticulously controlled multi-stage process, ensuring consistent metallurgical properties and superior welding characteristics. This process integrates advanced engineering with stringent quality control, adhering to international standards such as ISO 2560 and ANSI/AWS A5.1 for carbon steel electrodes.

Core Material Preparation:

- Steel Wire Rod Selection: High-grade low carbon steel wire rods are selected, typically with precise chemical compositions (e.g., C: 0.05-0.12%, Mn: 0.3-0.6%, Si: 0.1-0.3%). This ensures the core wire possesses the necessary tensile strength and ductility.

- Surface Cleaning: The wire rods undergo pickling and washing to remove rust, scale, and contaminants, ensuring optimal adherence of the flux coating.

- Wire Drawing: The cleaned rods are cold-drawn through a series of dies to achieve the desired diameter (e.g., 2.5mm, 3.2mm, 4.0mm), enhancing surface finish and mechanical properties.

Flux Coating Extrusion:

- Flux Formulation: A complex blend of mineral components (e.g., cellulose, rutile, iron powder, silicates) and binding agents (e.g., sodium silicate, potassium silicate) is prepared. This flux is crucial for arc stabilization, slag formation, shielding the weld pool from atmospheric contamination, and alloying the weld metal. For E6013 electrodes, a rutile-based flux is common, providing smooth arc and easy slag removal.

- Extrusion Process: The prepared flux paste is extruded onto the wire rods under high pressure, ensuring a concentric and uniform coating thickness. This process is often automated for precision.

Drying and Curing:

- Initial Drying: Electrodes are passed through low-temperature ovens to remove surface moisture.

- Baking/Curing: A critical step where electrodes are baked at precise temperatures (e.g., 200-450°C) for specific durations. This process hardens the flux, removes residual moisture, and activates the chemical components of the flux, impacting the electrode's performance, especially its moisture resistance and tendency for hydrogen-induced cracking.

Finishing and Quality Control:

- Tip Preparation: The striking end of each electrode is often cleaned or tipped to facilitate easier arc initiation.

- Visual Inspection: Each electrode undergoes thorough visual inspection for defects in flux coating, concentricity, and length.

- Mechanical & Chemical Testing: Batches are subjected to destructive weld tests, including tensile strength, yield strength, elongation, impact toughness (Charpy V-notch), and chemical analysis of the weld metal to ensure compliance with specifications like AWS A5.1 E6013.

- Packaging: Electrodes are typically vacuum-sealed or packaged in moisture-resistant materials to maintain their integrity until use.

The rigorous adherence to these process steps guarantees that carbon sticks for welding deliver a consistent, stable arc, excellent weld bead appearance, and reliable mechanical properties, crucial for demanding industrial applications.

Industry Trends and Market Dynamics

The market for carbon rods for welding is constantly evolving, driven by advancements in material science, increased automation in manufacturing, and a global push towards sustainable practices. Key trends include:

- Enhanced Performance Requirements: Industries like automotive, aerospace, and energy are demanding electrodes that offer higher strength-to-weight ratios, improved fatigue resistance, and better corrosion resistance in diverse operating environments. This pushes manufacturers to innovate flux formulations and core wire compositions.

- Automation and Robotics Compatibility: With the rise of robotic welding, there's a growing need for electrodes with extremely consistent quality, stable arc characteristics, and minimal spatter to ensure uninterrupted and high-quality automated operations.

- Environmental Regulations: Stricter environmental standards are driving the development of welding consumables with lower fume emissions and reduced hazardous substances, aligning with global sustainability goals.

- Focus on Productivity and Efficiency: End-users seek electrodes that offer higher deposition rates, easier slag removal, and reduced post-weld cleaning, translating into significant cost and time savings.

Technical Specifications and Parameters (E6013 Carbon Steel Welding Electrode)

E6013 is one of the most widely used general-purpose rutile-type mild steel electrodes, known for its smooth arc, low spatter, and easy slag removal. It's suitable for AC and DC welding in all positions, making it highly versatile for various fabrication and maintenance applications. The following table outlines typical specifications:

E6013 Welding Electrode Rods for Carbon Steel: Typical Specifications

Application Scenarios and Target Industries

The versatility and reliable performance of carbon steel welding rod make them indispensable across a broad spectrum of industrial applications. Their ease of use, even for less experienced welders, positions them as a go-to choice for general fabrication and repair.

- Petrochemical Industry: Used in the fabrication and maintenance of pipelines, storage tanks, and structural components within refineries and chemical plants. The electrodes ensure robust welds capable of withstanding varying temperatures and pressures.

- Metallurgy and Heavy Manufacturing: Employed in the construction of heavy machinery, equipment frames, and structural steelworks in steel mills and foundries. Their ability to deliver strong, reliable welds is crucial for heavy-duty applications.

- Water Supply & Drainage Infrastructure: Critical for welding water pipes, sewage treatment plant components, and other hydraulic structures. The electrodes provide leak-proof joints essential for fluid conveyance systems.

- Shipbuilding and Marine Applications: Utilized in the construction and repair of ship hulls, offshore platforms, and marine equipment where mild steel components are prevalent.

- General Fabrication: From automotive chassis to agricultural equipment and ornamental ironwork, these electrodes are a staple for general-purpose welding due to their forgiving nature and good aesthetic finish.

- Maintenance and Repair: Ideal for on-site repairs of various mild steel structures and components where ease of use and good all-position characteristics are required.

The average service life of a correctly applied weld using these electrodes is typically commensurate with the base material's expected lifespan, often extending decades with proper design and maintenance, underscoring their long-term value.

Technical Advantages: Why Choose These Carbon Steel Welding Electrodes?

Choosing the right carbon steel welding electrode offers distinct advantages that translate into operational efficiency, cost savings, and enhanced product quality:

- Superior Arc Stability: Rutile-type flux coatings provide an exceptionally smooth and stable arc, minimizing spatter and making it easier for welders to control the weld pool, even in challenging positions.

- Excellent Weld Appearance: These electrodes consistently produce finely rippled, smooth weld beads with excellent aesthetic appeal, often requiring minimal post-weld finishing.

- Easy Slag Removal: The flux creates a thin, easily detachable slag layer that peels off effortlessly, significantly reducing cleanup time and labor costs.

- Versatile All-Position Welding: Capable of welding in flat, horizontal, vertical-up, vertical-down, and overhead positions, offering maximum flexibility for diverse fabrication needs.

- Good Gap Bridging: Effective at bridging gaps in poorly fitted joints, which can often occur in field repair or general fabrication, thereby increasing productivity.

- Suitable for Low Open-Circuit Voltage (OCV) Machines: Can be used with a wide range of welding machines, including those with lower OCVs, common in smaller workshops or portable units.

- Energy Efficiency: The stable arc and efficient metal transfer reduce arc time, contributing to energy savings over large-scale welding projects.

- Corrosion Resistance (within mild steel limits): While not specifically a corrosion-resistant alloy, the clean, uniform welds produced by these electrodes provide a solid base that, when protected by appropriate coatings, contribute to the overall corrosion resistance of the mild steel structure.

Vendor Comparison: Choosing the Right Partner for Your Welding Needs

Selecting a supplier for carbon sticks for welding involves more than just comparing price lists. A holistic evaluation considering product quality, certifications, customer service, and technical support is crucial. Below is a comparative overview focusing on key differentiators:

Key Differentiators in Welding Electrode Suppliers

Customized Solutions for Specific Project Demands

Recognizing that standard products may not always meet every unique project requirement, leading manufacturers offer customized solutions for carbon rods for welding. This tailored approach ensures optimal performance even in specialized applications.

Customization options can include:

- Modified Flux Formulations: Adjusting flux chemistry to enhance specific properties like increased deposition rate, improved low-temperature impact toughness, better moisture resistance, or reduced fume generation.

- Specialized Diameters and Lengths: Producing electrodes in non-standard sizes to fit particular automated welding systems or manual applications requiring extended reach or compact design.

- Tailored Packaging: Custom packaging solutions, such as specific coil weights for robotic feeders, or enhanced moisture-barrier packaging for extreme environmental conditions (e.g., high humidity marine environments).

- Certification to Specific Industry Standards: Ensuring the product not only meets general AWS standards but also complies with more rigorous client-specific or industry-specific certifications (e.g., for pressure vessel codes, nuclear applications, or specific naval requirements).

Through close collaboration with clients, technical teams can develop and qualify bespoke welding electrodes, guaranteeing fit-for-purpose solutions that drive project success and operational excellence.

Application Case Studies: Real-World Success with E6013 Electrodes

Case Study 1: Large-Scale Pipeline Fabrication in the Energy Sector

A major energy infrastructure project required the welding of several kilometers of carbon steel pipelines. The challenge was to achieve high deposition rates while maintaining stringent quality and mechanical properties in diverse field conditions, including all-position welding. Using E6013 carbon steel welding electrode, the project team achieved:

- Productivity Increase: The smooth arc and easy slag removal minimized inter-pass cleaning time, leading to a 15% increase in welding speed compared to previous electrodes.

- Reduced Rework: Consistent weld quality and minimal spatter significantly reduced the rate of defects, cutting rework costs by an estimated 10%.

- Enhanced Operator Comfort: The stable arc and low fume levels contributed to improved working conditions for welders, reducing fatigue over long shifts.

Case Study 2: Structural Repairs for Municipal Water Treatment Facility

A municipal water treatment plant needed urgent repairs to several mild steel structural supports and pipe hangers that had suffered corrosion. The repairs often involved welding in confined spaces and overhead positions. The E6013 carbon rods for welding were chosen due to their excellent all-position capability and user-friendliness.

- Versatility in Confined Spaces: The stable arc and predictable performance allowed welders to execute high-quality welds even in difficult access areas.

- Reliable Structural Integrity: Post-repair inspections confirmed that the welds met all necessary structural and safety standards, ensuring the long-term integrity of the facility's infrastructure.

- Minimal Downtime: The quick and efficient welding process, coupled with easy slag removal, enabled rapid repairs, significantly reducing facility downtime.

Trustworthiness & Customer Support

Frequently Asked Questions (FAQ)

Q1: What is the primary difference between E6013 and E7018 electrodes?

A1: E6013 is a rutile-type electrode known for smooth arc, easy slag, and good appearance, ideal for general purpose and light fabrication. E7018 is a low-hydrogen, basic-type electrode designed for high-strength, critical applications requiring superior mechanical properties and resistance to hydrogen cracking, often requiring pre-baking.

Q2: Can E6013 electrodes be used with any welding machine?

A2: E6013 electrodes are highly versatile and can be used with both AC and DC (straight or reverse polarity) welding machines. They are particularly forgiving and work well with machines that have lower open-circuit voltages.

Q3: How should carbon rods for welding be stored to maintain quality?

A3: Electrodes should be stored in dry conditions, ideally in sealed, moisture-proof packaging, away from humidity and temperature fluctuations. While E6013 is less sensitive to moisture than low-hydrogen electrodes, proper storage extends shelf life and prevents potential porosity.

Q4: What are the typical lead times for bulk orders?

A4: Lead times for bulk orders typically range from 2-4 weeks, depending on order volume and specific customization requirements. We maintain substantial stock for standard products to facilitate rapid fulfillment.

Lead Time & Fulfillment

Our robust supply chain and manufacturing capabilities ensure efficient order processing and timely delivery. For standard orders, lead times are typically 7-14 business days. For customized solutions or large-volume contracts, a detailed production and delivery schedule will be provided, generally ranging from 3 to 6 weeks. We offer flexible shipping options, including sea freight, air freight, and expedited courier services, to meet diverse project timelines globally.

Warranty Commitments

All our carbon rods for welding are backed by a comprehensive quality warranty, guaranteeing products are free from manufacturing defects and meet all specified AWS A5.1 and ISO 2560 standards. In the unlikely event of a product quality issue, we commit to prompt investigation and appropriate resolution, including replacement or credit, ensuring client satisfaction and minimizing operational disruption. Our commitment to quality is underpinned by our ISO 9001 certified quality management system.

Customer Support Information

Our dedicated customer support team is available to assist with technical queries, order tracking, and any post-sales support. We provide multi-channel support including email, phone, and online portals. Our technical application engineers are also available for in-depth consultations to optimize your welding processes and material selection. For immediate assistance, please visit our website or contact us directly.

Contact: [Your Company Contact Information - e.g., sales@steeltoolschina.com | +86-XXX-XXXX-XXXX]

References

- American Welding Society (AWS) A5.1/A5.1M:2012, Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding.

- International Organization for Standardization (ISO) 2560:2020, Welding consumables - Covered electrodes for manual metal arc welding of non-alloy and fine grain steels - Classification.

- The Welding Institute (TWI) - "Selection of shielded metal arc welding (SMAW) electrodes."

- Lincoln Electric - "Electrode Selection Guide for SMAW."

- Esab Welding & Cutting Products - "SMAW Electrode Handbook."

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025