Quality Manufacturers of 316L Welding Rods for Wholesale Supply and Industrial Applications

An Overview of 316L Stainless Steel Welding Rod Manufacturers

The welding industry has witnessed a significant transformation over the years, particularly with the growing need for high-quality materials that meet stringent performance standards. Among these materials, 316L stainless steel has emerged as a preferred choice for many applications due to its excellent corrosion resistance, high strength, and ease of fabrication. As a result, the demand for 316L welding rods has surged, leading to an increase in the number of manufacturers specializing in this niche.

Understanding 316L Stainless Steel

316L stainless steel is a low-carbon version of 316 stainless steel, which is renowned for its resistance to pitting and crevice corrosion, especially in chloride environments. The “L” designation indicates a lower carbon content, which enhances its weldability and minimizes the risk of carbide precipitation during welding. This property makes 316L an ideal choice for industries such as oil and gas, chemical processing, and marine applications, where robust and durable materials are critical.

The Role of Welding Rods

Welding rods are essential components in the welding process, acting as a filler material that helps join two metal pieces. In the case of 316L, welding rods are used for applications that require exceptional strength and resistance to harsh environments. Manufacturers often provide various types of 316L welding rods, including solid rods and flux-cored variants, to cater to a wide range of welding techniques, such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas).

Key Considerations for Selecting 316L Welding Rod Manufacturers

1. Quality Assurance When selecting a manufacturer, it's crucial to assess their quality control processes. Leading manufacturers often adhere to international standards such as ISO 9001, ensuring that their products meet rigorous quality and reliability benchmarks.

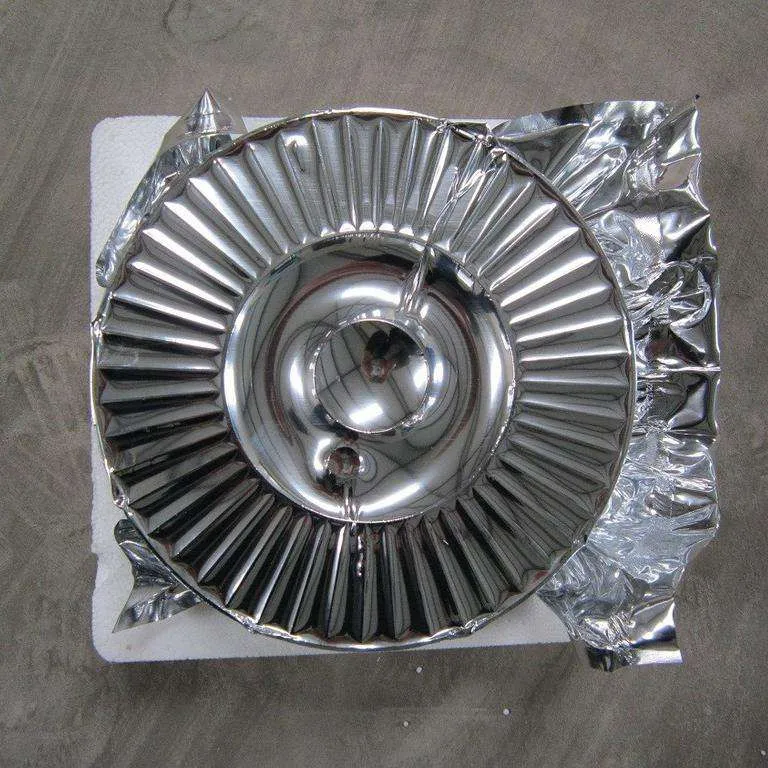

wholesale 316l-16 welding rod manufacturers

2. Material Specifications Ensure that the manufacturer provides detailed specifications of their 316L welding rods, including chemical composition, mechanical properties, and certifications. This information is vital for ensuring compatibility with your specific welding requirements.

3. Experience and Expertise The experience of a manufacturer in producing 316L welding rods can significantly influence the quality of the products. Established manufacturers typically have a wealth of knowledge regarding best practices, production techniques, and industry standards.

4. Customer Support and Service Strong customer support is essential, particularly for businesses that may require technical assistance or guidance. Manufacturers that offer robust support can help customers navigate challenges that may arise during the welding process.

5. Pricing and Availability Competitive pricing is an essential factor, but it should not compromise quality. Consider suppliers who offer reasonable prices without sacrificing the integrity of their products. Additionally, evaluate the availability of the welding rods, as delays in supply can impact project timelines.

The Competitive Landscape

The market for 316L welding rods is competitive, with numerous manufacturers vying for market share. This competition drives innovation and quality improvements as companies look to differentiate themselves from one another. Many manufacturers also invest in research and development to enhance the performance characteristics of their welding rods, striving to meet evolving industry demands and regulatory requirements.

Conclusion

In conclusion, the manufacturers of 316L stainless steel welding rods play a pivotal role in the welding industry, providing essential materials that meet the high standards required for various applications. By considering quality, experience, customer support, and pricing, consumers can make informed choices that ensure successful welding outcomes. As the industry continues to evolve, the emphasis on high-quality materials and innovative solutions will persist, further solidifying the importance of reputable 316L welding rod manufacturers in the marketplace.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025