Quality MIG Solid Wire Production for Enhanced Welding Performance and Reliability by Leading Manufacturer

Understanding MIG Solid Wire Manufacturers A Key to Quality Welding

Gas Metal Arc Welding (GMAW), commonly known as MIG (Metal Inert Gas) welding, is a widely used welding process that employs a continuous solid wire electrode fed through a welding gun. This method is favored for its speed, versatility, and ease of use, making it an ideal choice for both amateur welders and seasoned professionals. At the heart of successful MIG welding lies the quality of the solid wire used, which is why MIG solid wire manufacturers play a pivotal role in the welding industry.

What is MIG Solid Wire?

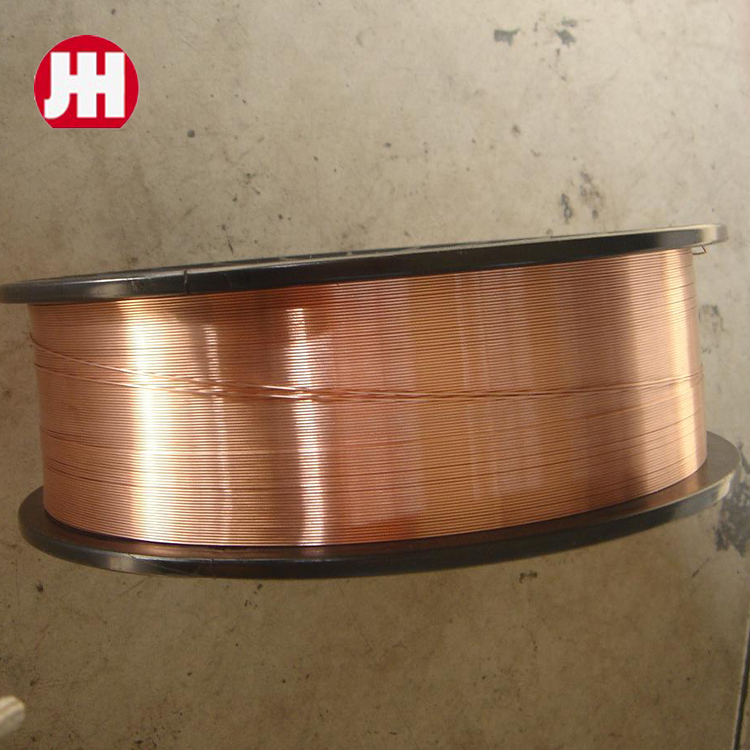

MIG solid wire is a type of electrode made from metals such as steel, stainless steel, or aluminum. The wire is typically coated with a thin layer of copper to enhance conductivity and prevent corrosion. The solid wire is continuous, providing a steady feed into the welding gun, ensuring a smooth welding arc and consistent results. Different alloy compositions, diameters, and coatings meet specific requirements tailored to the welding environment and the materials being welded.

The Role of MIG Solid Wire Manufacturers

MIG solid wire manufacturers are responsible for producing high-quality welding wires that adhere to industry standards. They play a critical role in ensuring the durability, strength, and reliability of welds by developing solid wires that cater to various applications. The manufacturing process involves numerous stages, including careful selection of raw materials, precision manufacturing techniques, and rigorous quality control measures.

Leading MIG solid wire manufacturers invest heavily in research and development to enhance their products. By leveraging the latest technologies and innovations, they strive to produce wires that improve arc stability, reduce spatter, and increase overall efficiency. These qualities are particularly important for industries such as automotive, construction, and shipbuilding, where strong and reliable welds are crucial.

Quality Assurance in Manufacturing

mig solid wire manufacturer

Quality control is paramount for MIG solid wire manufacturers. Each batch of wire undergoes extensive testing for mechanical properties, chemical composition, and weldability. This ensures that the wire not only conforms to specified standards but also performs exceptionally well in real-world applications. Manufacturers often follow international standards like AWS (American Welding Society) and ISO certifications, which help in maintaining product reliability and consistency.

Moreover, advanced techniques such as metallographic analysis and tensile testing are employed to evaluate the wire’s performance under various conditions. Manufacturers also provide detailed specifications and certifications for their products, offering welders confidence in the material they are using.

Choosing the Right MIG Solid Wire Manufacturer

When selecting a MIG solid wire manufacturer, several factors should be considered. It’s essential to evaluate the manufacturer’s reputation, experience, and the range of products they offer. A reliable manufacturer will also provide technical support and guidance in selecting the right wire for specific applications, helping customers achieve optimal results.

Furthermore, reviews and testimonials from other users can provide insights into the performance of the wire and the service quality from the manufacturer. It is also advisable to check if the manufacturer keeps up with advancements in welding technology and invests in innovation.

Conclusion

MIG solid wire manufacturers are an indispensable part of the welding ecosystem, ensuring that welders have access to high-quality materials that enable them to create strong, reliable welds. With the increasing demand for efficient and robust welding solutions across various industries, the role of these manufacturers has never been more critical. As the industry evolves, so too will the innovations surrounding MIG solid wire production—an exciting prospect for both manufacturers and welders alike.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025