Reliable Manufacturer of High-Quality Welding Wire for Various Industrial Applications and Projects

Exploring the World of 1% Welding Wire Manufacturers

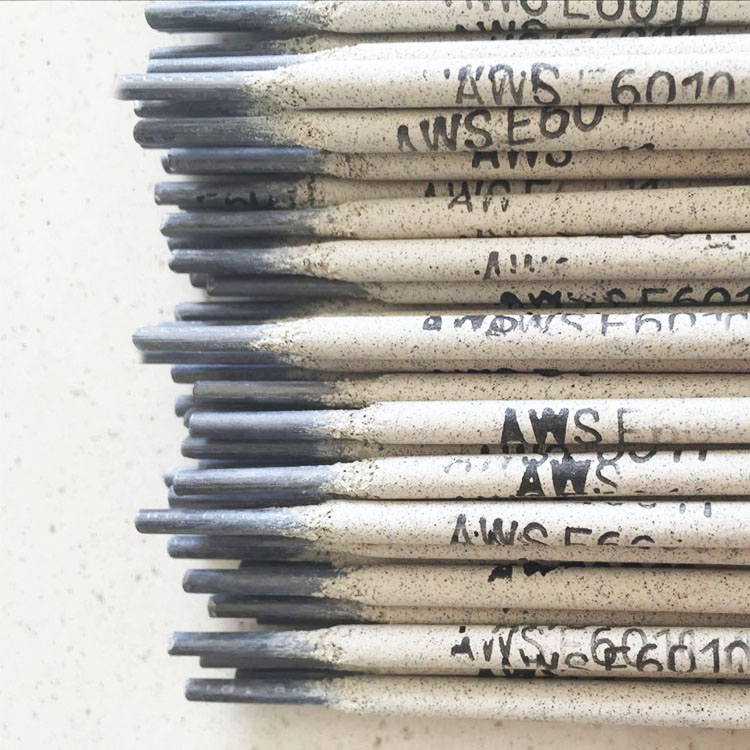

Welding is a critical process in various industries, from construction and automotive manufacturing to shipbuilding and aerospace engineering. The quality of the welding wire used in these applications directly influences the strength, durability, and safety of the final product. Among the myriad of welding wires available, 1% welding wire has garnered particular attention due to its unique properties and applications.

1% welding wire typically refers to welding wires that contain 1% alloying elements, such as nickel or molybdenum. These elements enhance the mechanical properties of the weld, making it more resilient to stress and environmental factors. As industries demand higher performance materials, the role of specialized welding wire manufacturers becomes increasingly vital.

What Makes 1% Welding Wire Special?

The inclusion of 1% alloying agents in welding wire serves several purposes. For instance, in welding applications where increased toughness and tensile strength are required, 1% nickel is often added to the wire composition. This results in welds that can endure extreme conditions, including high temperatures and severe stress. Such properties are essential in industries like oil and gas, where equipment often faces harsh environments.

Moreover, 1% welding wire is known for its excellent impact resistance and ductility. These characteristics are crucial in maintaining joint integrity in dynamic applications, such as in structural steelwork and heavy machinery assembly. As manufacturers strive to meet stringent safety standards, the reliability of the welding wire becomes paramount.

Choosing a Reliable Manufacturer

1 0 welding wire manufacturer

Choosing the right welding wire manufacturer is essential for any project that requires high-quality welding. A reputable manufacturer of 1% welding wire will typically invest in research and development to ensure their products meet industry standards and customer expectations. Many top manufacturers adhere to international quality standards such as ISO 9001, which guarantees a commitment to quality management and continuous improvement.

When evaluating potential suppliers, it's necessary to consider their production capabilities, quality assurance mechanisms, and experience in the industry. A manufacturer that utilizes advanced technology and equipment can produce welding wires that consistently meet specifications and performance criteria. Additionally, those manufacturers that engage in rigorous testing of their products will offer greater confidence in their reliability and effectiveness.

The Impact of Market Trends

The global welding market is ever-evolving, influenced by technological advancements and changing customer needs. As industries strive for more efficient and durable solutions, the demand for specialized welding wires, including 1% welding wire, is on the rise. These shifts are prompting manufacturers to innovate continuously, developing new alloys and production methods to stay competitive.

Moreover, sustainability is becoming a significant factor in the manufacturing process. Leading welding wire manufacturers are exploring environmentally friendly materials and processes to minimize their carbon footprint. This trend not only caters to environmentally conscious consumers but also ensures compliance with increasingly strict regulations governing industrial emissions.

Conclusion

1% welding wire plays a crucial role in many industrial applications, providing enhanced mechanical properties and reliability. As industries demand higher performance materials, the choice of a competent manufacturer becomes essential. By focusing on quality, innovation, and sustainability, manufacturers of 1% welding wire are poised to meet the challenges of the future. For businesses and professionals relying on welding processes, selecting the right welding wire can make a significant difference in the success and safety of their projects. In this competitive landscape, staying informed about manufacturers and their offerings can lead to better outcomes in the welding domain.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025