Electrode Manufacturers for Welding Industry Insights and Innovations

The Role of Electrode Manufacturers in the Welding Industry

Welding is a critical process in various industrial, construction, and manufacturing sectors, serving as the backbone for creating strong and lasting joints in materials. A crucial component in the welding process is the electrode, which serves as a filler material, allowing for the joining of metals. The importance of electrode manufacturers, particularly in the context of soldador electrodos or welding electrodes, cannot be overstated, as they play a vital role in the quality, safety, and efficacy of welding operations.

Understanding Welding Electrodes

Welding electrodes come in several types and forms, primarily differentiated by the welding process they are used for, such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and stick welding. Each type of electrode is designed to meet specific requirements in terms of the materials being welded, the thickness of the metal, and the desired qualities of the joint. For instance, MIG welding uses a continuously fed wire electrode, while stick welding relies on coated electrodes that melt during the welding process to create the weld pool.

The Process of Manufacturing Welding Electrodes

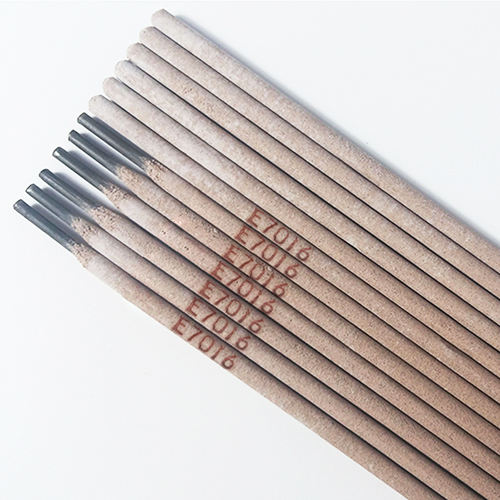

The manufacturing of welding electrodes is a meticulous process that involves sourcing high-quality raw materials, precision engineering, and strict adherence to safety and quality standards. Manufacturers typically start with high-grade alloys and metals, combined with various coatings to enhance performance and protect against contamination. The importance of these coatings cannot be overlooked, as they play a pivotal role in stabilizing the arc and producing a smooth, clean weld.

Advanced manufacturing techniques such as extrusion and wire drawing are used to shape electrodes to specific dimensions. Once created, these electrodes undergo rigorous testing to ensure they meet industry standards and specifications. This quality control is essential as it affects the performance of the electrodes in real-world applications.

Innovation and Technology in Electrode Manufacturing

soldador electrodos manufacturers

As the welding industry evolves, so too do the technologies and methodologies employed by electrode manufacturers. Recent advancements have centered around improving the efficiency and effectiveness of welding processes. New materials and coatings are being researched and incorporated, which not only enhance the mechanical properties of the welded joint but also improve the overall sustainability of the manufacturing process.

Moreover, the rise of automation in manufacturing has enabled producers to maintain higher consistency and quality in their products. Automated production lines can keep track of various parameters in real-time, ensuring that any deviations are corrected immediately, thereby maintaining the integrity of the electrodes.

The Economic Impact of Electrode Manufacturers

The economic implications of electrode manufacturers extend beyond the welding industry itself. By contributing to the production of high-quality welds, these manufacturers enable other sectors—such as automotive, aerospace, and construction—to produce reliable structures and components, thereby enhancing overall safety and performance. A strong welding joint can prevent catastrophic failures, showcasing the necessity of well-manufactured electrodes.

Furthermore, as industries seek to optimize costs and improve productivity, the role of electrode manufacturers in providing innovative and effective solutions becomes paramount. Research and development investments can lead to new products that not only meet current demands but also anticipate future trends and industry needs.

Conclusion

In conclusion, the role of electrode manufacturers in the welding industry is both complex and crucial. Through their commitment to quality, innovation, and sustainability, they ensure that welders have access to reliable materials, enabling them to create safe and durable products. As technology advances and the industry continues to evolve, these manufacturers will undoubtedly remain at the forefront, playing a key role in shaping the future of welding. This steadfast dedication to excellence not only enhances the welding process but also contributes to the broader economic landscape, underscoring the interconnectedness of different sectors in the modern economy.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025