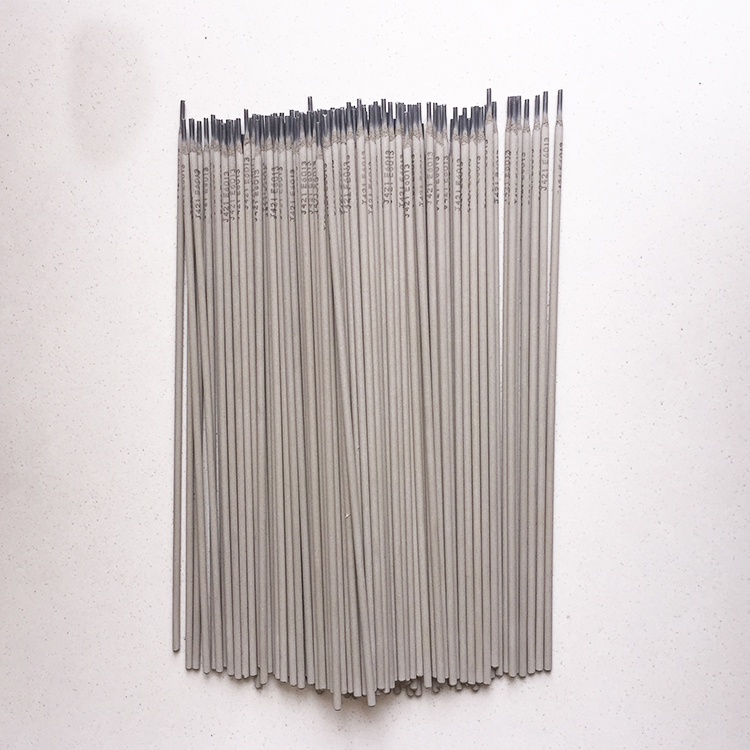

Electrode 6011 Welding Techniques and Factory Production Processes Explored

Understanding E6011 Electrodes in Welding Factories

Welding is a critical process in various industries, and among the essential tools used in the process are welding electrodes. One of the most recognized types of these electrodes is the E6011. Known for its versatility and adaptability, E6011 electrodes are widely utilized in factories and workshops around the globe. In this article, we will explore the characteristics, applications, and advantages of E6011 electrodes in welding operations.

What are E6011 Electrodes?

The E6011 welding electrode is classified under the American Welding Society (AWS) specifications. The E stands for electrode, while the numbers 6011 indicate the minimum tensile strength and the type of welding current the electrode can handle. Specifically, the 60 signifies a minimum tensile strength of 60,000 psi, and the 11 denotes the electrode's ability to perform well with alternating current (AC) and direct current (DC) in all positions.

Characteristics of E6011 Electrodes

E6011 electrodes are known for their exceptional qualities

1. Versatility These electrodes can be utilized for different types of welding processes, including flat, horizontal, vertical, and overhead positions. This makes them suitable for diverse applications, from small repairs to heavy industrial fabrication.

2. Penetration One of the most significant advantages of E6011 electrodes is their deep penetration capability. They produce a strong weld that can withstand stress and strain, making them ideal for jobs requiring high strength.

3. Forgiving nature E6011 electrodes can easily handle dirty or rusty surfaces, which is often a limitation with other electrode types. This characteristic allows welders to work in less-than-ideal conditions, ensuring that quality welds can still be achieved.

4. Good arc stability The E6011 features good arc characteristics, leading to smooth operation. The consistent arc stability allows for more precise and controlled welding, which is crucial in industrial settings.

Applications of E6011 Electrodes

soldadura electrodos 6011 factories

Due to their versatility and strong performance characteristics, E6011 electrodes are used in various applications, including

- Structural Fabrication In building structures and industrial frameworks, E6011 electrodes can handle the demands of heavy materials and the stress of load-bearing conditions. - Repair Work Their ability to weld through contaminants makes E6011 electrodes ideal for repair jobs in manufacturing and maintenance scenarios. Welders often use them to fix machinery, vehicles, and construction equipment. - Farm Equipment Given the rugged and often harsh environments agricultural equipment operates in, E6011 electrodes are commonly employed in the repair and fabrication of farm tools and machinery.

- Pipe Welding The excellent penetration and arc stability make them suitable for pipe welding applications, ensuring strong joints that are necessary for pipelines in various industries.

Advantages of Using E6011 Electrodes in Factories

The advantages of choosing E6011 electrodes extend to various aspects of welding operations in factories

1. Cost-Effectiveness E6011 electrodes are typically more affordable than some specialty electrodes, making them a sensible choice for factories looking to optimize costs without compromising quality.

2. Ease of Use The forgiving nature of E6011 electrodes means that they are easier for inexperienced welders to use, thus reducing training time and improving overall efficiency in the workplace.

3. Low Spatter Compared to many other electrode types, E6011 generates less spatter during the welding process. This means reduced cleanup time and improved working conditions for welders.

4. Wide Availability Being among the most popular welding electrodes, E6011 is readily available in most welding supply stores, ensuring that factories can easily procure them without delays.

Conclusion

E6011 electrodes are a reliable and versatile choice for various welding applications in factories and workshops. From their deep penetration capabilities to their forgiveness in working with dirty materials, they provide welders with the tools they need to complete jobs effectively and efficiently. As the industry continues to evolve, E6011 electrodes will undoubtedly remain a staple in welding operations, contributing to the quality and durability of products and structures in a multitude of fields.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025