Top Stainless Steel MIG Welding Wire Suppliers for Reliable Performance and Quality

Understanding Stainless MIG Welding Wire Manufacturers

Welding is an essential process in manufacturing and construction, allowing for the joining of materials, particularly metals. Among the various welding techniques, Metal Inert Gas (MIG) welding stands out for its simplicity and versatility, making it a popular choice across industries. When it comes to welding stainless steel, the quality of the MIG welding wire is crucial. Therefore, understanding stainless MIG welding wire manufacturers is vital for anyone in the field.

What is Stainless MIG Welding Wire?

Stainless MIG welding wire is a type of filler material used in MIG welding to weld stainless steel. It comes in various diameters and compositions, tailored to meet different welding requirements. Typically made from austenitic stainless steel, the wire often contains alloys such as chromium and nickel, which enhance corrosion resistance and overall strength.

Importance of Quality in Manufacturing

The quality of MIG welding wire is paramount. A reputable manufacturer ensures that their products meet industry standards, providing consistent performance and reliability. High-quality stainless MIG wires reduce the likelihood of welding defects, such as porosity, spatter, and lack of fusion, which can compromise the integrity of the welded structure. Consequently, skilled manufacturers invest in advanced production techniques and rigorous testing protocols.

Key Features of a Reliable Manufacturer

When selecting a stainless MIG welding wire manufacturer, several key features should be considered

1. Certifications and Standards A reputable manufacturer adheres to international standards such as ISO 9001, ensuring their products are consistently manufactured according to rigorous quality guidelines. Compliance with industry-specific certifications, such as ASME or AWS, is also critical, especially for applications in critical sectors like aerospace, nuclear, and automotive industries.

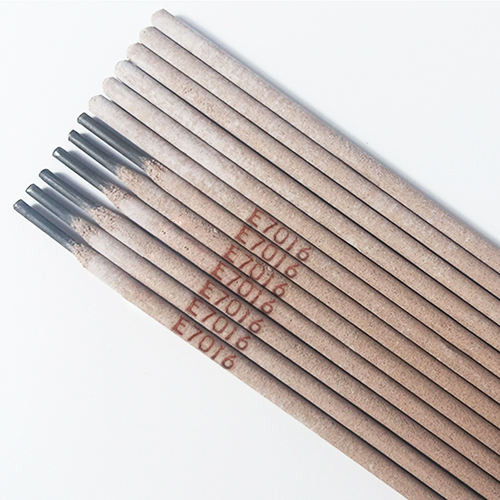

stainless mig welding wire manufacturer

2. Raw Material Sourcing The quality of raw materials directly impacts the performance of the welding wire. Leading manufacturers source high-grade stainless steel from trusted suppliers, ensuring that the chemical composition of their wires meets specific welding applications. Transparency in sourcing materials also boosts consumer trust and confidence.

3. Product Range A reliable manufacturer offers a diverse product range. Different applications require various wire types, such as ER308L, ER316L, or ER2209, each suited for specific welding processes or environments. A manufacturer that can provide a comprehensive selection allows for tailored solutions to meet various operational needs.

4. Technological Advancements In today's competitive landscape, innovation is key. Top manufacturers invest in research and development to enhance the qualities of their welding wires, focusing on improving performance characteristics such as feedability, arc stability, and deposition rates. Furthermore, adopting modern production technologies ensures efficiency and consistency in quality.

5. Customer Support and Services Good manufacturers understand the importance of customer relationships. Look for those that provide exemplary customer service, technical support, and training resources. This level of support is especially beneficial for businesses aiming to optimize their welding processes and improve overall productivity.

Sustainability and Environmental Considerations

As industries worldwide strive for sustainability, many stainless MIG welding wire manufacturers are prioritizing eco-friendly practices. This includes reducing waste during production and adopting sustainable sourcing practices. Manufacturers who are committed to environmental responsibility not only contribute positively to the planet but also appeal to an increasingly eco-conscious clientele.

Conclusion

Selecting the right stainless MIG welding wire manufacturer is integral to achieving high-quality welding results. From understanding the importance of quality in manufacturing to recognizing the characteristics of reputable suppliers, making informed choices enhances the overall welding process. As demand for reliable, high-performance welding solutions grows, manufacturers who focus on quality, innovation, and customer service will continue to lead the market. For anyone in the welding industry or involved in welding projects, investing in high-quality stainless MIG welding wire from reputable manufacturers is a crucial step towards achieving excellence in welding outcomes.

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025