stainless welding electrodes manufacturer

Stainless Welding Electrodes A Comprehensive Insight into Manufacturers and Their Importance

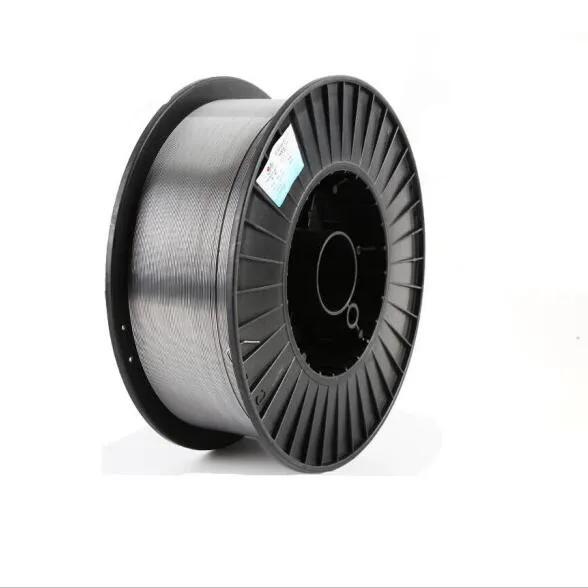

Stainless welding electrodes are crucial components in the welding industry, particularly when it comes to joining stainless steel materials. The use of these electrodes ensures strong, durable welds that can withstand various environmental conditions. As industries increasingly gravitate towards stainless steel due to its corrosion resistance and aesthetic appeal, the demand for high-quality stainless welding electrodes continues to rise.

Stainless Welding Electrodes A Comprehensive Insight into Manufacturers and Their Importance

One of the key considerations for manufacturers is the type of welding process the electrodes are designed for. Common processes include Shielded Metal Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), and Gas Metal Arc Welding (GMAW). Each of these methods requires specific electrode compositions to ensure optimal weld quality. For instance, electrodes designed for SMAW might differ significantly in flux composition compared to those intended for GTAW or GMAW.

stainless welding electrodes manufacturer

In addition to the technical aspects, manufacturers also focus on the training and support of their customers. Providing detailed specifications and usage guidelines is essential to help welders achieve the best results. Furthermore, manufacturers often invest in research and development to innovate and improve their product lines. This helps them keep pace with technological advancements and the evolving needs of their clients across various sectors, including construction, aerospace, automotive, and food processing.

Sustainability is another important trend influencing manufacturers of stainless welding electrodes. With increasing awareness of environmental issues, many companies are exploring ways to reduce waste and increase the recyclability of their products. This can include using more sustainable materials in electrode production and improving manufacturing efficiencies.

In conclusion, stainless welding electrode manufacturers play a crucial role in ensuring the quality and performance of welded stainless steel applications. Their commitment to innovation, quality control, and customer support ensures that industries relying on these materials can maintain high standards in their projects. As demand continues to grow, these manufacturers will be at the forefront of providing solutions that meet both performance and sustainability needs. Investing in reputable manufacturers can ultimately lead to better outcomes in any welding project, safeguarding both the integrity of the materials used and the safety of the finished product.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025