steel mig welding wire supplier

Understanding the Role of Steel MIG Welding Wire Suppliers

In the world of metal fabrication, MIG (Metal Inert Gas) welding has gained immense popularity due to its efficiency, versatility, and ease of use. The choice of welding wire is crucial to the success of any MIG welding project, and this strikes at the heart of the necessity for reliable steel MIG welding wire suppliers. A good supplier not only provides high-quality materials but also contributes positively to the overall welding process, impacting everything from welding performance to material costs.

The Importance of Steel MIG Welding Wire

MIG welding utilizes a continuous wire feed as the electrode, which contributes to a smooth and stable arc. Steel MIG welding wire is specifically designed to fuse ferrous metals, which are prevalent in various industries ranging from construction to automotive manufacturing. One of the primary benefits of using quality steel welding wire is its ability to provide strong and durable welds that can withstand considerable stress and strain.

Key Considerations When Choosing a Supplier

When searching for the right steel MIG welding wire supplier, several factors should be considered

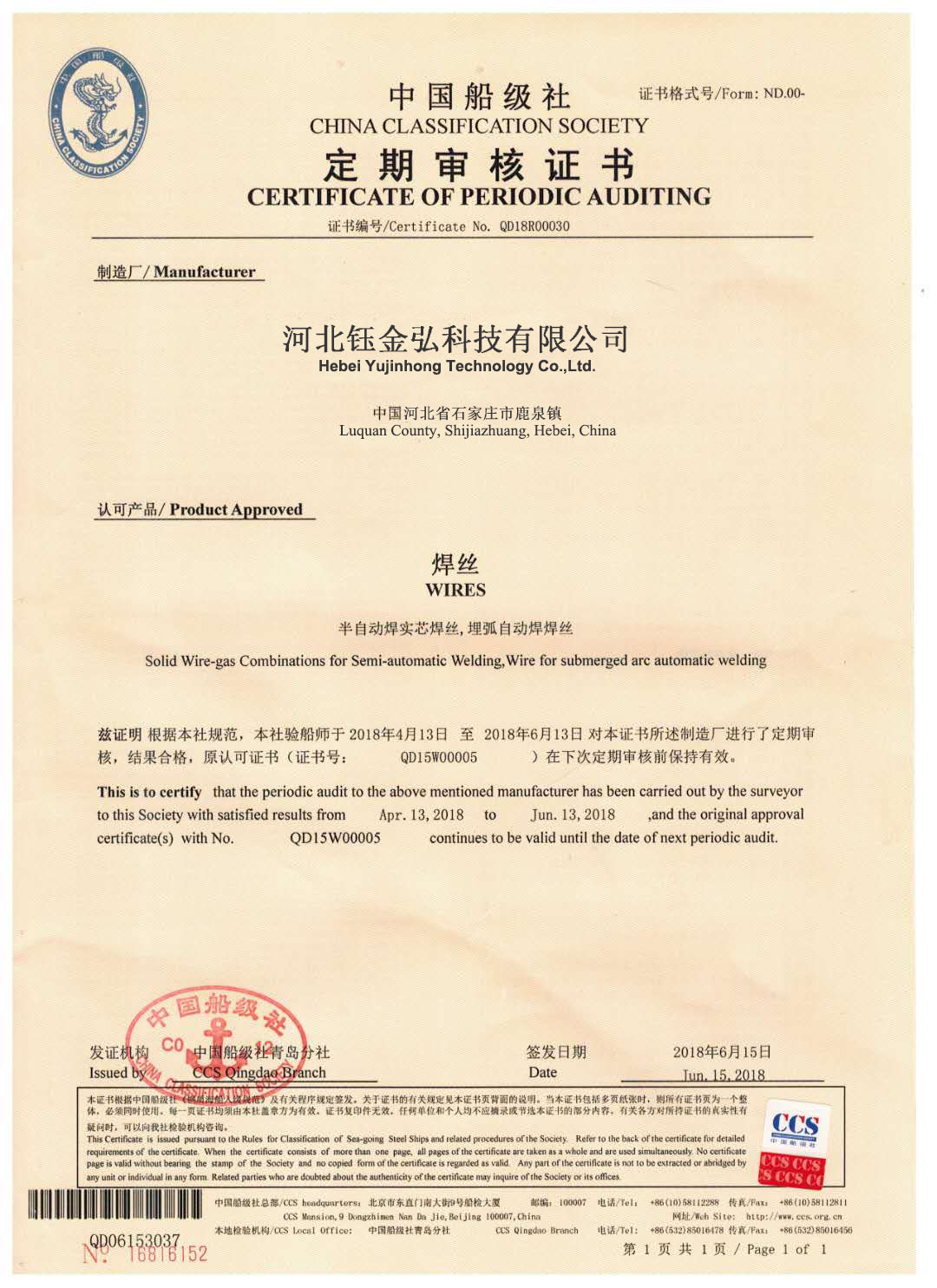

1. Quality of Wire The most critical aspect of choosing a welding wire supplier is the quality of their products. High-quality steel MIG welding wire should meet certain industry standards and specifications. It's essential to select a supplier who offers wires that are tested for performance and reliability.

2. Range of Products Different projects require different types of welding wires, such as ER70S-6 or ER70S-3, which are common choices for carbon steel welding. A comprehensive supplier should offer a variety of welding wires to address the unique needs of your projects, including various diameters and wire compositions.

3. Technical Support and Expertise A good steel MIG welding wire supplier often provides technical guidance and support for customers. This may include assistance in choosing the right wire for specific applications, as well as insights into welding techniques and best practices.

steel mig welding wire supplier

4. Pricing Structure Cost is always a consideration when sourcing materials. It's vital to find a supplier that balances quality with competitive pricing. Bulk purchasing options and loyalty programs can also help reduce costs over time.

5. Delivery and Availability Consistent and timely delivery can greatly impact production schedules. A reliable supplier should be able to maintain stock levels and ensure that orders can be fulfilled promptly, reducing downtime in your operations.

Building Long-Term Relationships

Establishing a long-term relationship with a steel MIG welding wire supplier can prove beneficial for businesses engaged in metal fabrication. Long-standing partnerships often lead to better pricing, enhanced service, and a deeper understanding of a company’s specific needs. Suppliers familiar with your production processes can make recommendations that enhance efficiency and quality, ultimately helping you achieve better results.

The Future of MIG Welding Supplies

As technology evolves, so too do the materials available for MIG welding. Suppliers are continuously exploring new alloys and wires manufactured to enhance weld quality and performance. Furthermore, with the upswing in eco-friendly practices, there is a growing demand for sustainable welding materials. A forward-thinking supplier should stay abreast of these innovations and ensure their offerings are aligned with current industry trends.

Conclusion

In conclusion, the role of steel MIG welding wire suppliers is crucial in the landscape of metal fabrication. The quality of welding wire directly affects the integrity of welds and the success of projects. By considering factors such as product quality, range, technical support, pricing, and reliability, welding professionals can select a supplier that meets their needs effectively. Building a strong partnership with a trusted supplier not only enhances operational efficiency but also ensures access to the best materials for accomplishing high-quality welding tasks. Thus, understanding and appreciating the importance of selecting the right steel MIG welding wire supplier can be a game-changer for businesses focused on delivering excellence in their welding operations.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025