Optimal MIG Welding Wire Selection for Steel Fabrication and Performance

The Importance of Choosing the Right MIG Welding Wire for Steel Welding

MIG welding, or Metal Inert Gas welding, is one of the most commonly used welding techniques, especially for steel. It offers a fast and efficient way to join metals together, making it a preferred method in various industries, including automotive, construction, and manufacturing. However, the success of MIG welding relies heavily on selecting the right type of MIG welding wire. This article delves into the significance of using the appropriate MIG wire for steel welding, the various types available, and tips for choosing the best option for your specific needs.

Understanding MIG Welding Wire

MIG welding wire is a continuous wire electrode that is fed through a welding gun, creating a weld pool that melts and fuses the base metals together. The wire's composition and diameter are crucial factors affecting the quality and strength of the weld joint. For steel welding, the most commonly used types of wires are ER70S-6, ER70S-3, and flux-cored wires, each offering distinct advantages depending on the application and environment.

Types of MIG Welding Wire for Steel

1. ER70S-6 This is one of the most popular wires for MIG welding mild steels. It contains higher levels of manganese and silicone, which improve its deoxidizing properties and make it suitable for welding dirty or rusty materials. ER70S-6 is particularly effective in applications where good impact toughness is needed, making it ideal for construction and heavy-duty welding.

2. ER70S-3 This wire is similar to ER70S-6 but has a lower level of deoxidizers. It is commonly used for clean environments where the base metal is free from contaminants. ER70S-3 is a versatile choice for general steel fabrication and is suitable for welding thin to medium-gauge sheets.

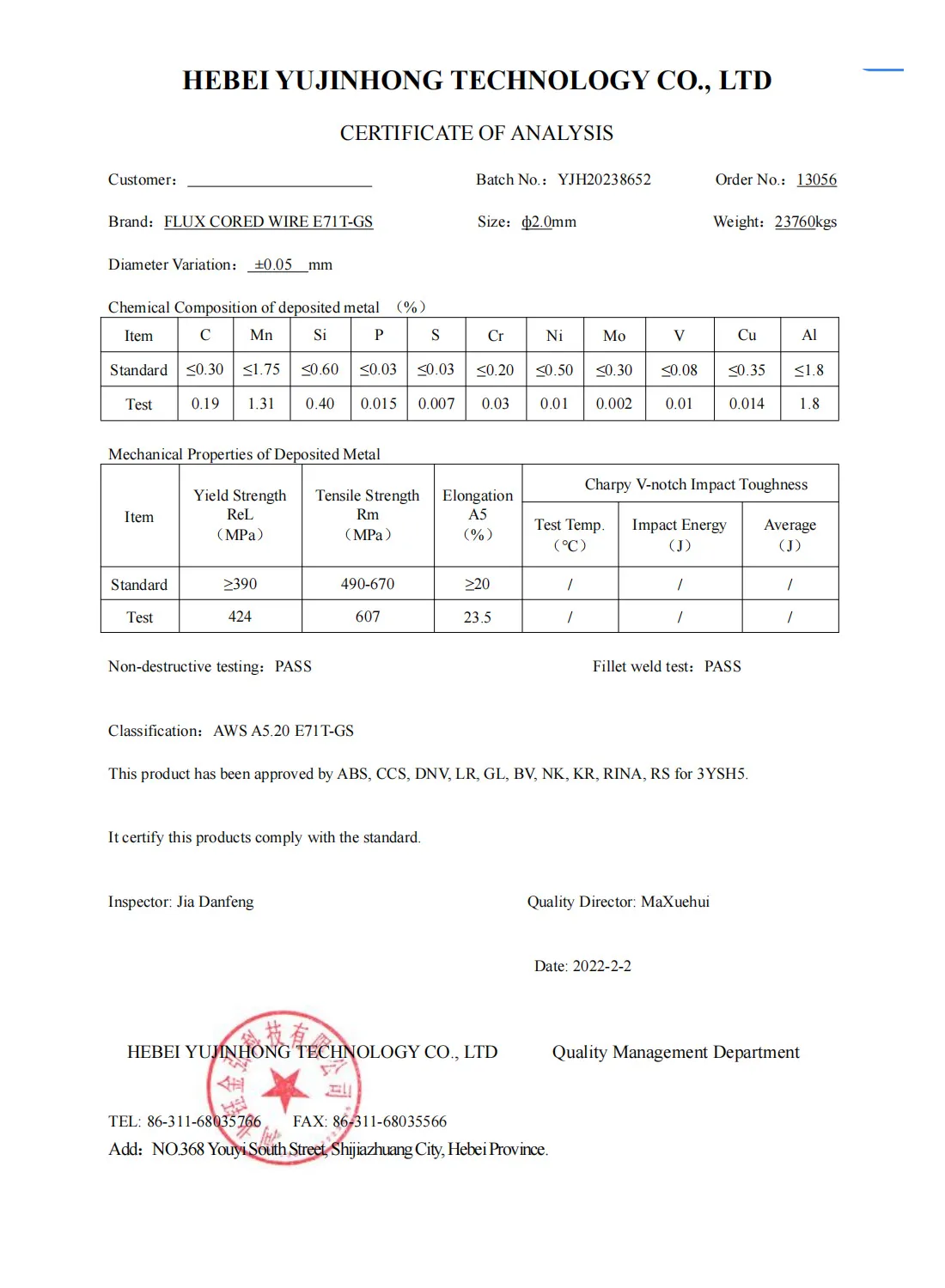

3. Flux-Cored Wire Flux-cored welding wire is often used in outdoor environments where wind can affect the shielding gas. It is designed with a core of flux to produce its shielding properties, making it suitable for welding thicker sections of steel. While it can produce a higher deposition rate, it generally requires more post-weld cleanup due to slag formation.

The Impacts of Wire Selection

steel welding mig wire

Choosing the right MIG wire for steel welding is crucial, as it directly influences the weld quality, appearance, and strength. Using the wrong type of wire can lead to various issues, including poor penetration, weak weld joints, excessive spatter, and difficulties in achieving a clean finish. Moreover, selecting the appropriate wire also involves considering the welding position, base material thickness, and environmental conditions.

Factors to Consider When Choosing MIG Wire

1. Material Thickness For thin materials, it is essential to use a smaller diameter wire, typically 0.030 inches or 0.035 inches. For thicker materials, larger diameter wires are preferable. This ensures better heat control and penetration, reducing the risk of burn-through.

2. Welding Position Different welding positions (flat, horizontal, vertical, overhead) may require different types of wire. For example, while performing vertical or overhead welding, a flux-cored wire may help in preventing sagging due to its flux core mechanisms.

3. Base Metal Condition Always assess the condition of the base metal. If you are welding clean metal, a standard solid wire will work effectively. However, for rusty or dirty materials, opting for a higher deoxidizer content wire like ER70S-6 is advisable.

4. Environmental Factors Consider where the welding will take place. External conditions such as wind can impact the performance of shielding gas; in such cases, flux-cored wires might be a better choice.

Conclusion

In conclusion, selecting the right MIG welding wire for steel is a fundamental aspect of achieving a high-quality weld. By understanding the differences between the types of wires available and considering specific factors like material thickness, welding position, base metal condition, and environmental conditions, welders can ensure they make the best choice for their projects. A well-chosen MIG wire not only enhances the welding process but also contributes to the durability and integrity of the final product, making it a key component in successful steel welding applications.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025