Top Suppliers for Stick MIG Welding Equipment and Accessories

The Importance of Choosing the Right Stick MIG Welding Supplier

Welding is an essential process used in various industries, from construction to automotive manufacturing. Among the myriad of welding techniques available, Stick MIG (Metal Inert Gas) welding has emerged as a popular choice due to its versatility, efficiency, and ease of use. However, the success of any welding project heavily relies on the quality of equipment and materials used, which underscores the importance of selecting the right stick MIG welding supplier.

Understanding Stick MIG Welding

Before delving into the selection of a supplier, it's crucial to understand what Stick MIG welding involves. This technique combines the advantages of stick welding and MIG welding, utilizing a continuous wire feed for superior speed and efficiency. It is ideal for a wide range of applications, including thick materials, outdoor work, and environments where wind or drafts might interfere with other welding processes.

The versatility of stick MIG welding makes it suitable for various metals, such as steel, aluminum, and other alloys. However, to achieve the best results, it is critical to use high-quality welding wires, power sources, and consumables that match the specific requirements of a project.

Why Supplier Quality Matters

When it comes to stick MIG welding, the quality of the supplier can significantly impact the outcome of your projects. A reliable supplier provides the necessary equipment, materials, and technical support that can make a difference in performance and outcomes. Here are several factors that demonstrate the importance of choosing the right supplier

1. Quality of Products The primary role of a supplier is to provide high-quality products. Subpar welding wires or machinery can lead to weak welds, increased downtime, and potential safety hazards on the job site. It is essential to work with suppliers known for their adherence to industry standards and quality control measures.

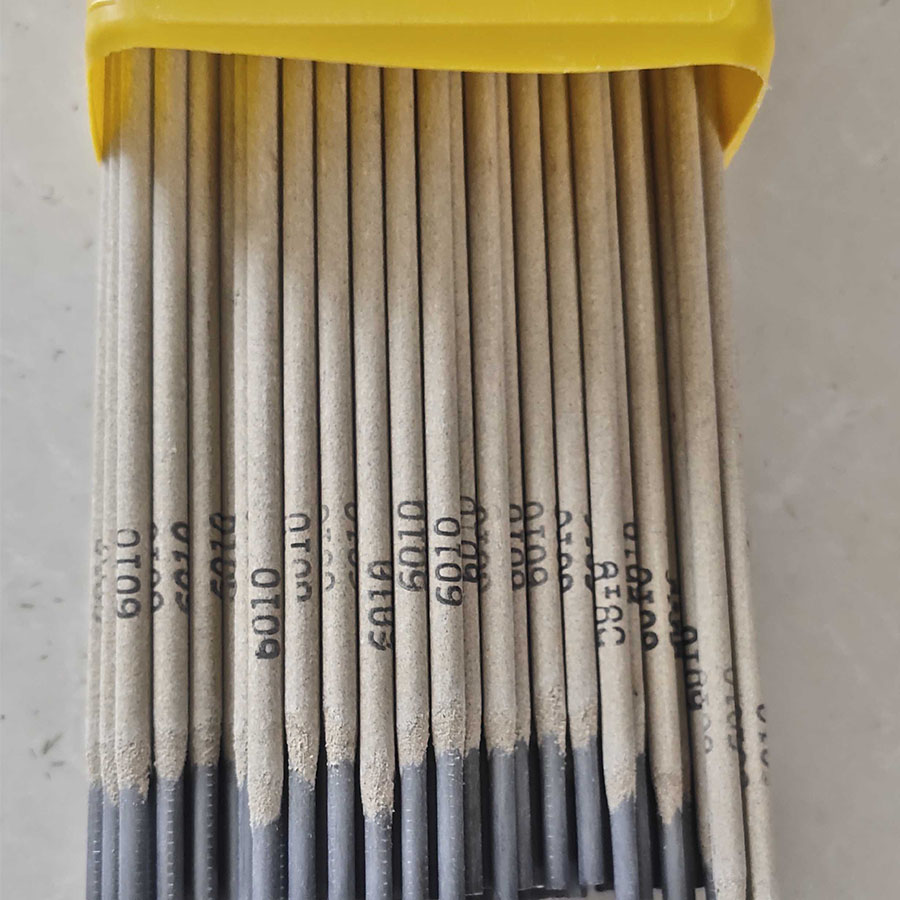

stick mig welding supplier

2. Variety and Availability Different welding applications may require varying materials and equipment. A great stick MIG welding supplier should offer a wide range of products, including different types of welding wires and equipment options, to meet specific project needs. The ability to source specialty wires or equipment on demand is a significant advantage.

3. Technical Support Welding can sometimes present challenges, especially when working with unfamiliar materials or techniques. A good supplier should offer technical assistance, helping customers select the right products and troubleshoot any issues that may arise during the welding process. Suppliers with knowledgeable staff can be invaluable, especially for less experienced welders.

4. Competitive Pricing Cost is always a consideration in any business decision. While quality should never be compromised, a competitive price point can help keep projects within budget. A reputable supplier often engages in transparent pricing and bulk purchasing options, which can be beneficial for businesses looking to save on costs.

5. Reputation and Reliability Finally, researching a supplier's reputation in the industry can provide insights into their reliability and customer service. Testimonials and reviews from past clients can guide you to suppliers who provide excellent service and high-quality products.

In Conclusion

Choosing the right stick MIG welding supplier is crucial for anyone involved in welding projects, whether on a large scale or in DIY endeavors. The impact of a quality supplier extends beyond mere access to products; it encompasses the assurance of best practices, technical support, and a commitment to safety and quality.

In the fast-evolving landscape of welding technology, staying updated with the latest advancements in materials and equipment through a reputable supplier will undoubtedly enhance your projects' success. By prioritizing these important factors, you can ensure not only the completion of your projects but their success in terms of quality and efficiency.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025