Stick Welding Rod Manufacturing Facility Overview and Production Insights

The Stick Welding Rod Factory A Crucial Player in the Welding Industry

In the realm of metal fabrication and construction, stick welding remains a widely used technique known for its versatility and robustness. At the heart of this process lies an essential component the welding rod. The manufacturing of these rods takes place in specialized facilities known as stick welding rod factories. These factories play a pivotal role in ensuring that welders have access to high-quality materials necessary for their work.

The Importance of Welding Rods

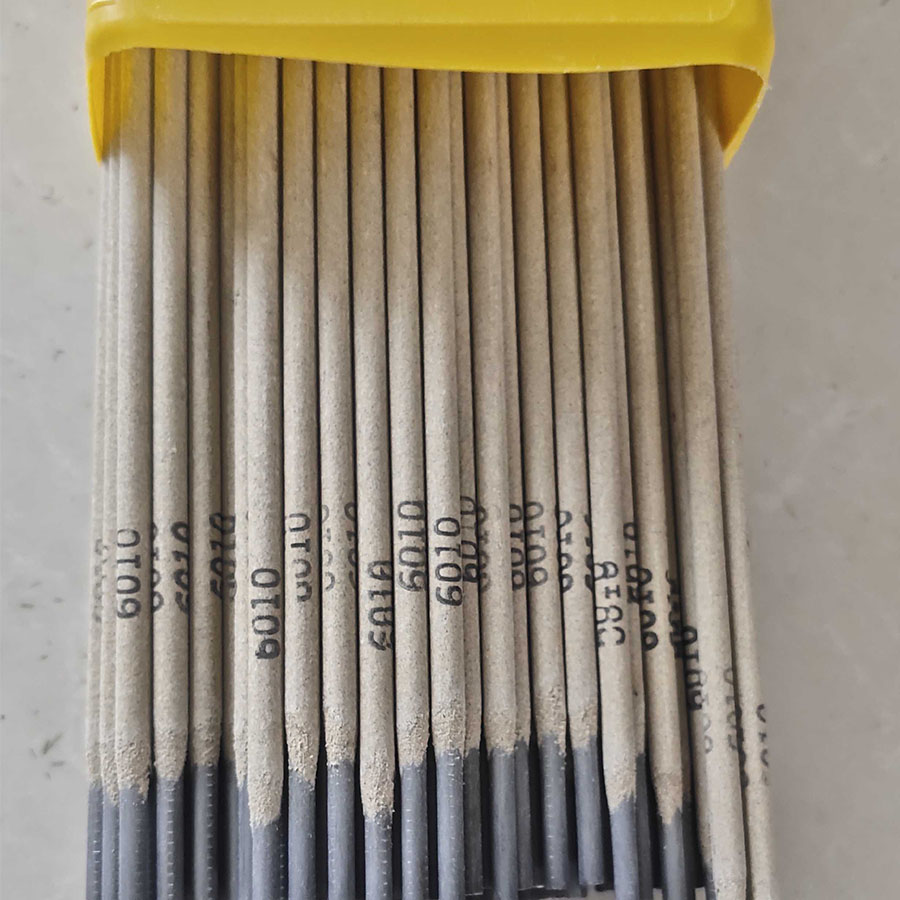

Welding rods, particularly those used in stick welding, are made of metal and coated with a flux material. The flux serves multiple purposes it protects the molten weld pool from contamination, stabilizes the arc, and adds alloying elements to the weld. Different types of rods are produced to cater to a variety of welding applications, including steel, stainless steel, and cast iron. Each rod is designed to provide specific properties that influence the strength, ductility, and resistance to corrosion of the resulting weld.

Overview of Manufacturing Processes

The production of stick welding rods involves several key processes, including material selection, rod formation, coating, drying, and quality control.

1. Material Selection The first step in manufacturing stick welding rods is selecting the appropriate materials based on the desired properties of the finished product. Raw materials, including metal powders and alloys, must be sourced from reliable suppliers to ensure consistency and quality.

2. Rod Formation After material selection, the metal is blended and formed into rods. This process can involve extruding or drawing the metal into specific diameters that meet industry standards. The choice of diameter affects the strength and application of the welding rods.

3. Coating Once the rods are formed, they undergo a coating process. The flux coating, which is essential for the welding process, is applied to the rods by dipping or extruding them into a mixture of materials. This coating not only protects the rod but also enhances its performance during welding.

stick welding rod factory

4. Drying and Curing After coating, the rods need to be dried and cured in a controlled environment to ensure that the coating adheres properly and to remove any moisture. Proper drying is crucial as moisture can compromise the quality of the weld by leading to porosity and other defects.

5. Quality Control Quality assurance is paramount in the production of welding rods. Factories employ rigorous testing methods, including visual inspections and mechanical tests, to ensure that the rods meet industry standards and specifications. Any rods that do not pass inspection are discarded or recycled, ensuring that only the best products reach customers.

The Role of Technology

Modern stick welding rod factories leverage advanced technology to improve efficiency and product quality. Computer-controlled machinery allows for precise calibration during the rod formation and coating processes, while automated inspection systems can quickly identify defects. Digital tracking systems help monitor inventory and production flow, ensuring timely delivery of products to customers.

Moreover, the integration of green manufacturing practices is becoming increasingly common. Factories are adopting sustainable methods to minimize waste and reduce their carbon footprint, aligning with global efforts to promote environmentally responsible manufacturing.

Market Demand and Trends

The demand for stick welding rods is influenced by various factors, including construction activities, infrastructure development projects, and the automotive industry. As economies grow, particularly in developing regions, the need for skilled welders and reliable welding materials proliferates. This trend creates opportunities for stick welding rod factories to expand their operations and invest in research and development to create innovative products.

Conclusion

Stick welding rod factories are vital to the welding industry, providing the necessary materials that enable effective and efficient welding processes. Through stringent quality controls and the embrace of modern technology and sustainable practices, these factories ensure that welders have access to high-quality rods that meet the increasingly demanding standards of the industry. As the global market continues to evolve, the significance of these manufacturers will only grow, highlighting their crucial role in advancing metal fabrication and construction projects worldwide.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025