Exploring Stainless Steel Stick Welding Techniques in Manufacturing Environments

The Role of Stick Welding in Stainless Steel Manufacturing

Stick welding, also known as Shielded Metal Arc Welding (SMAW), is a popular method used in various manufacturing industries, especially for the production of stainless steel components. This technique involves using an electrode coated in flux, which creates an arc between the electrode and the workpiece, melting both to form a solid bond. The adaptability, cost-effectiveness, and versatility of stick welding make it an attractive option for stainless steel factories.

Advantages of Stick Welding for Stainless Steel

1. Versatility in Applications Stick welding can be performed in various positions, making it ideal for a range of stainless steel applications. Whether it's vertical, horizontal, or overhead welding, this method provides the flexibility needed to tackle complex projects. It is particularly useful in situations where access to the weld site is limited, such as in piping or structural welding.

2. Cost-Effectiveness Compared to other welding methods, such as MIG or TIG welding, stick welding equipment is relatively inexpensive. The simplicity of the apparatus and the lower initial investment are significant advantages, particularly for small and medium-sized stainless steel factories. Additionally, the electrodes used in stick welding are readily available and do not require complicated setups, further reducing operational costs.

3. Minimal Equipment Requirements Stick welding only needs a welding machine, electrodes, and protective gear, making it easy to set up and operate. This minimal requirement allows for increased mobility and flexibility in manufacturing environments, where different projects may demand fast transitions between processes.

4. Robust and Strong Welds Stainless steel is widely used due to its strength and corrosion resistance characteristics. Stick welding allows for deeper penetration of welds and better overall joint strength due to the high heat generated. This results in durable and long-lasting connections, which are particularly crucial in applications such as food processing, pharmaceuticals, and chemical industries, where hygiene and integrity are paramount.

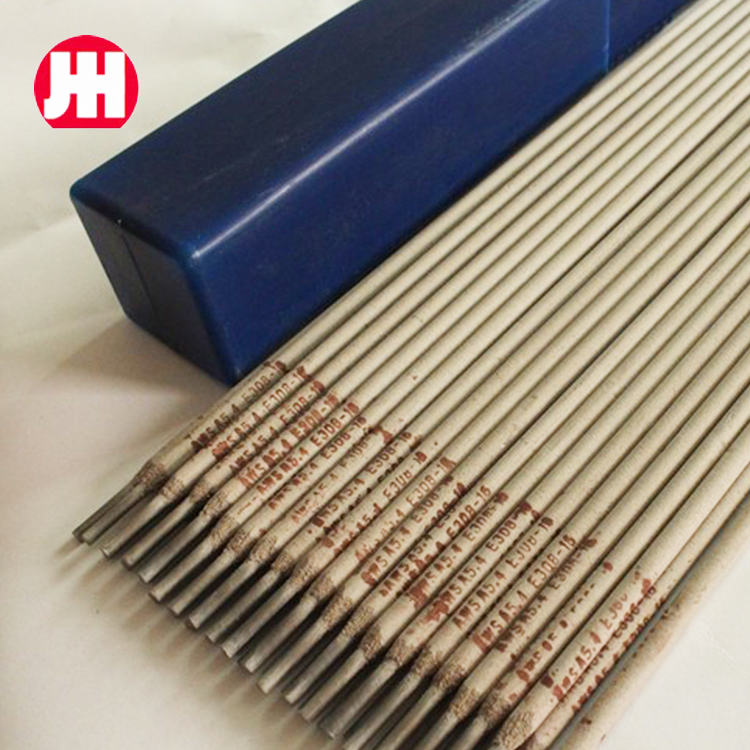

stick welding stainless factories

Challenges in Stick Welding Stainless Steel

Despite its advantages, stick welding stainless steel does present some challenges. One significant issue is the difficulty in controlling heat input, which can lead to warping or distortion in thinner materials. Stainless steel is also sensitive to contamination, and the presence of foreign particles can affect the quality of the weld. Therefore, proper surface preparation and cleanliness are vital.

Another challenge is the potential for weld defects, such as slag inclusions and undercutting. Skilled operators must frequently monitor their techniques and employ proper welding speeds and angles to mitigate these issues. Continuous training and adherence to best practices are essential for maintaining high welding standards.

The Future of Stick Welding in Stainless Steel Factories

As technology advances, the stick welding process continues to evolve, offering improved techniques and materials that enhance its application in stainless steel manufacturing. New electrode formulations are being developed to reduce spatter and improve the overall quality of welds. Additionally, automation and robotic stick welding systems are becoming more prevalent, allowing for greater precision and consistency in production.

The demand for stainless steel products is anticipated to grow, driven by industries such as automotive, aerospace, and construction. As a result, stainless steel factories are likely to continue embracing stick welding for its cost-effectiveness and adaptability, even as they explore hybrid processes that combine various welding techniques to optimize productivity and quality.

In conclusion, stick welding remains a vital part of stainless steel manufacturing, balancing flexibility, cost, and quality. By continually improving their processes and training their workforce, stainless steel factories can harness the full potential of stick welding, ensuring the production of strong and reliable products tailored to meet the demands of modern industries. As long as the challenges are managed effectively, stick welding will continue to hold an essential place in the landscape of stainless steel fabrication.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025