Supplier of E71T-GS MIG Wire for Exceptional Welding Performance in China

China E71T-GS MIG Wire Supplier A Comprehensive Overview

In recent years, the demand for high-quality welding materials has surged across various industries, spurring the growth of specialized suppliers. Among these, E71T-GS MIG wire has gained significant attention due to its superior performance in gas-shielded welding processes. This article provides an overview of E71T-GS MIG wire, its applications, and notable suppliers in China.

Understanding E71T-GS MIG Wire

E71T-GS is a type of flux-cored MIG wire specifically designed for welding mild and low-alloy steels. The E signifies that it is an electrode, while 71 refers to the minimum tensile strength of the weld metal in kilopounds per square inch (KSI), which is approximately 70 KSI. The T indicates that it is a tubular wire, and GS denotes its suitability for gas-shielded welding.

One of the key advantages of E71T-GS MIG wire is its versatility. It can be used in various positions, including flat, horizontal, and vertical, making it ideal for numerous applications, from construction projects to manufacturing and repair work. The wire's exceptional arc stability and low spatter generation further enhance its suitability for both skilled and novice welders.

Applications of E71T-GS MIG Wire

The E71T-GS MIG wire is employed in a multitude of applications, thanks to its ability to provide strong, clean welds. Common uses include

1. Automotive Repair The wire is often utilized in the repair of automotive parts and components due to its ability to weld easily with thin materials. 2. Construction In structural welding, E71T-GS is favored for its high-quality welds, making it suitable for building frameworks and supporting structures. 3. Manufacturing Many manufacturers prefer E71T-GS for fabricating machinery and equipment, as it can handle various steel grades.

china e71t-gs mig wire supplier

The Chinese Market for E71T-GS MIG Wire

China has emerged as a global leader in the production of welding materials, including E71T-GS MIG wire. The country boasts a plethora of suppliers offering this product, each with varying levels of quality and pricing. When selecting a supplier, several factors should be considered

1. Quality Assurance It’s crucial to choose a supplier that adheres to strict quality control measures. Many reputable suppliers conform to international standards such as ISO 9001, ensuring product consistency and reliability.

2. Cost-Effectiveness While price is an important factor, it shouldn’t overshadow quality. The best suppliers will provide competitive pricing without compromising on the wire’s integrity.

3. Customer Support Reliable suppliers offer comprehensive customer support, helping clients choose the right products for their specific welding needs.

4. Delivery and Logistics The ability to deliver goods promptly and handle logistics efficiently is essential, especially for businesses that rely on timely inventory replenishment.

Conclusion

In conclusion, the E71T-GS MIG wire is a vital component in various welding applications, known for its strength, versatility, and reliability. As the demand for such materials continues to grow, China remains a significant player in the global market, providing a wide array of suppliers. By focusing on quality, cost, customer support, and logistics, businesses can find the right E71T-GS MIG wire supplier to meet their welding needs effectively. Whether for construction, automotive, or manufacturing applications, the proper selection will ensure projects are completed with durability and efficiency.

-

Welding Cast Iron with Stainless Rods Durable, Rust-Resistant BondsNewsApr.29,2025

-

030 Flux Core Stainless Steel Welding Wire - Durable & Corrosion-ResistantNewsApr.29,2025

-

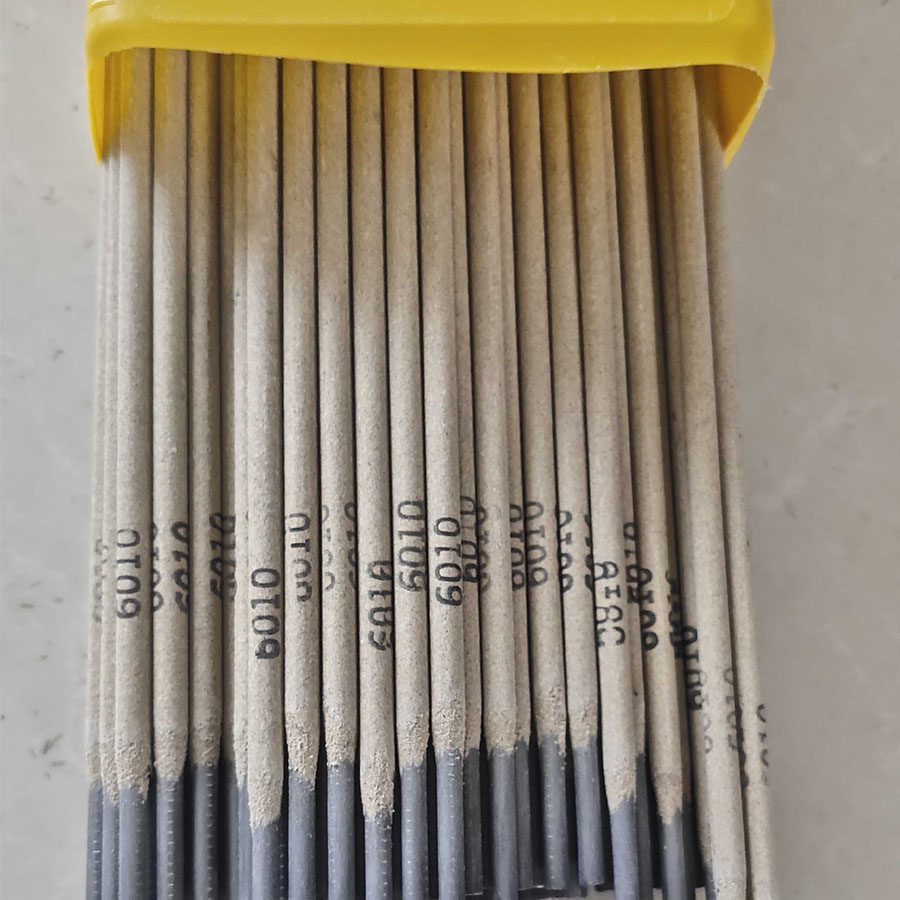

Premium 6010 1/8 Welding Rods China Factory & Wholesale SuppliersNewsApr.28,2025

-

E6013 Welding Rod Specs High-Performance Electrodes for Versatile WeldingNewsApr.28,2025

-

Metal Cored Welding Wire Supplier High-Quality & Durable SolutionsNewsApr.28,2025

-

Gasless MIG Wire for Smooth Aluminum Welding China Suppliers & FactoriesNewsApr.28,2025