Suppliers of High-Quality 0.9mm ER70S-6 Welding Wire for Durable and Reliable Welding Solutions

Understanding ER70S-6 Welding Wire A Focus on 0.9 mm Manufacturers in China

Welding is a crucial process in construction and manufacturing, and the choice of welding wire significantly affects the quality of the weld. One of the most commonly used welding wires is the ER70S-6, renowned for its excellent performance in various applications. This article explores the significance of 0.9 mm ER70S-6 welding wire, focusing on manufacturers from China.

What is ER70S-6 Welding Wire?

ER70S-6 is a type of solid wire used for gas metal arc welding (GMAW) or MIG (Metal Inert Gas) welding. The ER in the designation stands for electrode and filler rod, 70 indicates the minimum tensile strength of 70,000 psi, and S signifies that it is a solid wire. The -6 denotes specific chemical compositions and characteristics, making it suitable for welding on a variety of base metals.

One of the standout features of ER70S-6 is its deoxidizing elements, including silicon and manganese, which enhance its ability to produce clean and strong welds, particularly on rusty or dirty surfaces. This characteristic makes it a preferred choice for industries such as automotive, construction, and shipbuilding.

The 0.9 mm Diameter A Versatile Option

Welding wire comes in various diameters, with 0.9 mm being a popular choice for many applications. This diameter strikes a good balance between improved penetration and control, making it suitable for thin to medium thickness materials. It is particularly effective for applications involving mild steel, which is often used in structural fabrication and repair work.

The 0.9 mm ER70S-6 wire allows for higher welding speeds and minimizes heat distortion, which is crucial when working with thinner materials. As such, manufacturers often select this size for robotic welding applications, where precision is critical.

The Rise of Chinese Manufacturers

china welding wire 0.9 mm er70s-6 manufacturers

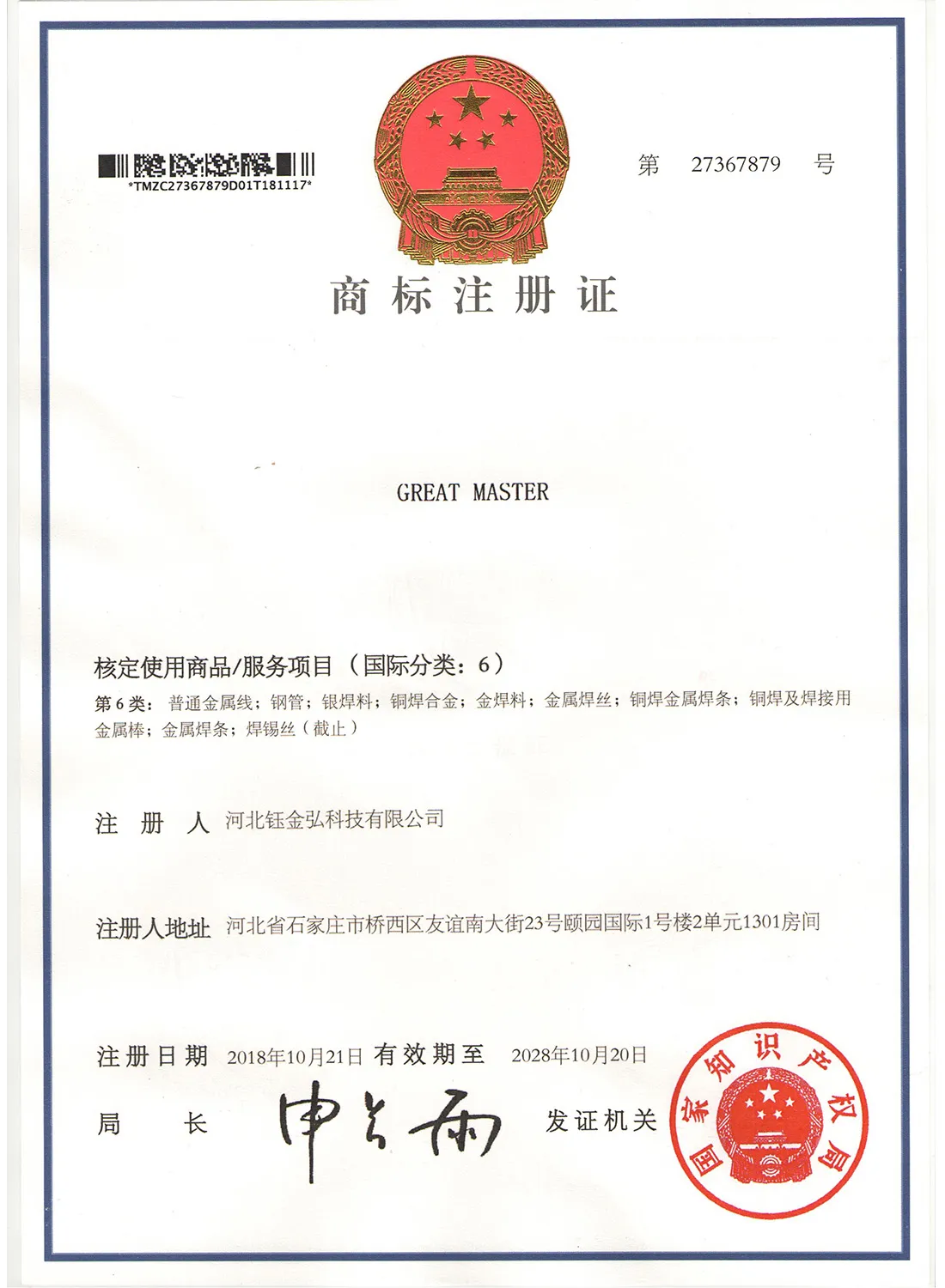

China has become a leading market for welding wire production, including ER70S-6. The country is home to numerous manufacturers that adhere to international standards, ensuring the quality and performance of their products. Among these, several companies stand out due to their advanced technology, efficient production processes, and commitment to innovation.

Chinese manufacturers leverage state-of-the-art machinery and quality control systems to produce welding wires that meet the stringent requirements of various industries. Moreover, they often offer competitive pricing, making them attractive options for companies looking to source welding consumables without compromising quality.

Advantages of Sourcing from Chinese Manufacturers

1. Cost-Effectiveness One of the primary advantages of sourcing ER70S-6 welding wire from China is cost savings. Due to lower labor and production costs, many manufacturers can offer competitive pricing while maintaining acceptable quality standards.

2. Wide Range of Options Many Chinese manufacturers produce a variety of welding wires, including different diameters and compositions. This flexibility allows businesses to find products that best suit their specific applications.

3. Quality Assurance Although there may be concerns about quality when sourcing products from overseas, many reputable Chinese manufacturers comply with international quality standards, such as ISO 9001. This adherence ensures that the products meet the expected performance metrics.

4. Rapid Shipping Options With well-established logistics networks, many Chinese manufacturers are able to provide efficient shipping solutions, reducing lead times for companies in need of rapid procurement.

Conclusion

In conclusion, the 0.9 mm ER70S-6 welding wire has become an essential tool in various industrial applications, offering versatility and quality welds. Manufacturers in China play a significant role in providing high-quality options for businesses worldwide. As the demand for efficient and reliable welding solutions continues to grow, the future of ER70S-6 wire production in China looks promising, ensuring that industries have access to the materials needed for successful welding operations. Whether you are a small fabricator or a large manufacturing operation, sourcing from Chinese manufacturers can provide the reliability and performance required in welding tasks, making them valuable partners in the industry.

-

Premium AC Stainless Steel Welding Rods for Durable JointsNewsSep.01,2025

-

E71T-GS Welding Wire: Versatile Flux Core for All-Position MIGNewsAug.31,2025

-

Premium Submerged Welding Wire: High Performance & ReliabilityNewsAug.30,2025

-

E7016 Welding Rods: High Strength Low Hydrogen for Critical WeldsNewsAug.29,2025

-

E71T-11 Flux Core Wire: Premium Gasless Welding SolutionNewsAug.28,2025

-

Premium Carbon Rods for Welding | Stable Arc & Precise GougingNewsAug.27,2025