Suppliers of High-Quality Stainless Steel Welding Electrodes for Industrial Applications and Projects

Stainless Steel Welding Electrodes Suppliers Your Guide to Quality and Reliability

In the world of metal fabrication and construction, stainless steel has emerged as a popular choice due to its excellent corrosion resistance, aesthetic appeal, and mechanical properties. However, the effectiveness of stainless steel welding largely depends on the quality of welding electrodes used. For professionals in the industry, sourcing reliable stainless steel welding electrodes suppliers is paramount to ensure smooth and effective welding processes.

Understanding Stainless Steel Welding Electrodes

Welding electrodes are crucial components in the welding process, acting as the conduit for the current that melts the base material and filler material. They come in various types, designed to meet specific requirements based on the properties of the stainless steel being welded.

The most common types of stainless steel welding electrodes include

1. E308 Ideal for welding austenitic stainless steels, this electrode is widely used for various applications due to its excellent weldability and corrosion resistance.

2. E309 This electrode is designed for welding dissimilar metals, particularly when combining carbon steels with stainless steels. It provides strong joints and resistance to wear.

3. E316 Known for its added molybdenum, E316 electrodes are favored for marine environments, as they offer superior resistance to corrosion.

When selecting the right electrode, it's important to analyze the specific materials, the welding process to be used (such as SMAW, GTAW, or FCAW), and the environmental factors that may affect the joint's integrity.

The Importance of Quality Suppliers

Choosing the right supplier for stainless steel welding electrodes can make a significant difference in the quality of the end product. High-quality electrodes lead to

stainless welding electrodes suppliers

- Better Weld Quality Quality electrodes ensure a smooth melt pool, leading to stronger and more aesthetically pleasing welds. - Increased Productivity Reliable electrodes minimize the chances of defects, reducing the need for rework and saving valuable time and resources. - Improved Safety Using proper materials can prevent issues such as weld failures, which can lead to accidents in high-stress environments.

Features to Look for in Suppliers

When searching for stainless steel welding electrodes suppliers, certain criteria can help you make an informed decision

1. Reputation Look for suppliers with strong reviews and testimonials in the industry. A reputable supplier is often a reliable source of quality materials.

2. Product Range Ensure the supplier offers a broad range of electrodes suitable for various welding applications. This flexibility can be crucial for businesses that handle diverse projects.

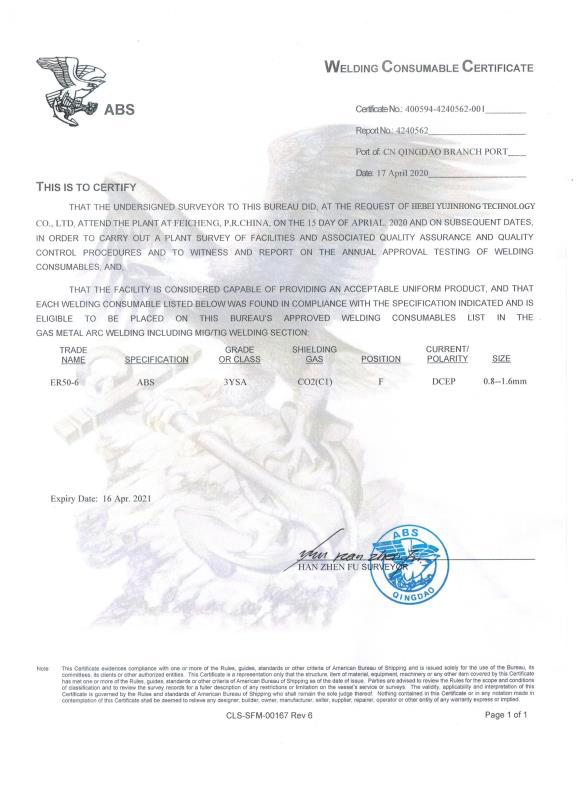

3. Certifications Check if the supplier's products meet industry standards and regulations. Certifications like ISO can be a good indicator of quality control.

4. Technical Support A good supplier should provide technical assistance and advice on electrode selection and welding techniques.

5. Pricing While quality should never be compromised for cost, it's important to find a supplier who offers competitive prices without sacrificing the integrity of the product.

Conclusion

In conclusion, the selection of stainless steel welding electrodes is critical to the overall success of welding projects. By partnering with reputable suppliers, businesses can ensure they obtain high-quality electrodes that enhance weld integrity, safety, and efficiency. Whether you’re a small fabrication shop or a large manufacturing facility, investing time in finding the right suppliers will pay off in the long run. Always keep in mind the significance of quality, support, and industry knowledge when sourcing your stainless steel welding electrodes.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025