Top Manufacturers of E6013 Welding Electrodes in China Leading Suppliers and Quality Products

The Rise of China’s Welding Electrode E6013 Factories

In recent years, China has emerged as a significant player in the manufacturing and exportation of welding electrodes, specifically the E6013 type. The E6013 electrode, known for its versatility and ease of use, is widely employed in various welding applications including shipbuilding, construction, and general fabrication. This article delves into the rise of China’s E6013 welding electrode factories, their technological advancements, production capacity, and the impact they have on both domestic and global markets.

The Rise of China’s Welding Electrode E6013 Factories

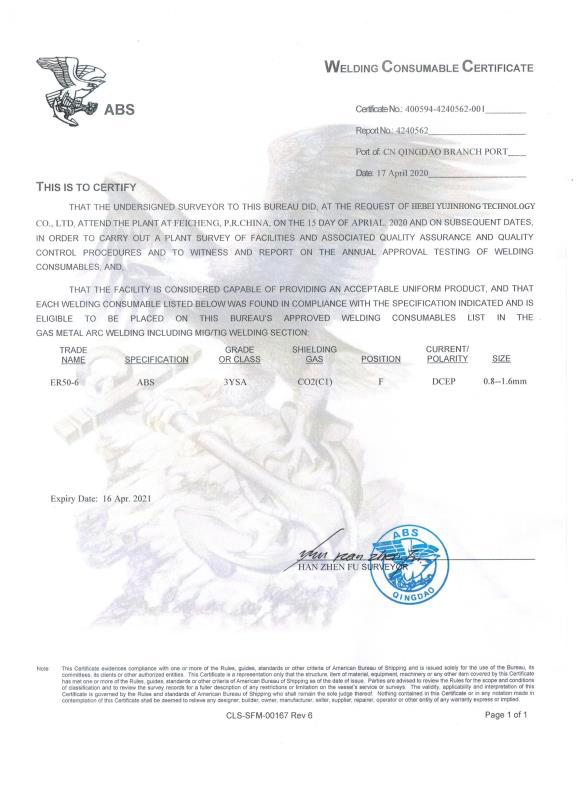

One of the driving forces behind the surge in Chinese E6013 electrode production is the country’s robust manufacturing infrastructure. China’s industrial sectors benefit from cost-effective labor, abundant raw materials, and government support, which collectively lower production costs and improve profit margins. Furthermore, Chinese factories often employ state-of-the-art manufacturing processes and strict quality control measures, ensuring that their products meet international standards such as those set by the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO).

china welding electrode e6013 factories

Technological innovation also plays a vital role in China's ascendance in this industry. Chinese welding electrode manufacturers have invested heavily in research and development to enhance the performance characteristics of the E6013 electrode. Innovations such as improved coating compositions, which enhance arc stability and reduce spatter, have made Chinese electrodes increasingly competitive. Moreover, advancements in automation and production techniques have boosted the efficiency and consistency of electrode manufacturing, resulting in higher quality products.

The global export network of Chinese E6013 welding electrodes is extensive, with products reaching markets in North America, Europe, Southeast Asia, and beyond. Chinese manufacturers often leverage strategic partnerships and distribution channels to penetrate these markets, offering competitive pricing and reliable supply chains. This global reach not only underscores the quality of Chinese-made electrodes but also solidifies China’s reputation as a leading supplier in the welding industry.

Domestically, the Chinese market for welding electrodes continues to grow, driven by the country’s expansive construction and infrastructure projects. From high-speed railways to skyscrapers, the demand for reliable and high-quality welding solutions remains robust. Chinese E6013 electrode factories are well-positioned to meet this domestic demand while simultaneously catering to international clients.

In conclusion, the rise of China’s E6013 welding electrode factories is a testament to the country’s industrial acumen and capacity for technological innovation. By combining cost-efficient production methods, cutting-edge technology, and stringent quality controls, China has established itself as a dominant force in the global welding electrode market. As the industry continues to evolve, Chinese manufacturers are likely to maintain their competitive edge, delivering high-quality electrodes that meet the diverse needs of welders worldwide.

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025