Top Manufacturers of Self-Shielding MIG Welding Wire in China for Quality Welds and Performance

Self-Shielding MIG Wire Manufacturers in China

In the realm of welding technologies, self-shielding MIG (Metal Inert Gas) wire has carved out a significant niche due to its versatility, efficiency, and ease of use. China's emergence as a leading manufacturer of self-shielding MIG wire has attracted attention from industries around the globe. This article delves into the characteristics, advantages, and the landscape of self-shielding MIG wire manufacturers in China.

Understanding Self-Shielding MIG Wire

Self-shielding MIG wire is designed to make the welding process simpler by eliminating the need for external shielding gas. This is particularly advantageous in environments where gas shielding is impractical due to wind or other conditions. The core of the wire is formulated with a blend of metals and additives that generate a protective gas during the welding process, thus safeguarding the weld pool from contaminants in the atmosphere.

Advantages of Self-Shielding MIG Wire

The self-shielding capability of MIG wire offers several benefits

1. Ease of Use Welders can operate in varied environmental conditions without the hassle of setting up gas bottles or adjusting gas flow rates. 2. Cost-Effective By removing the need for gas, manufacturers can reduce costs associated with gas cylinders and regulators, making it an economical choice for many applications.

4. Efficiency The process allows for quicker welding speeds, which can significantly enhance productivity on job sites.

5. Portability Without the need for gas cylinders, the equipment becomes more portable and convenient for use in remote locations or tight spaces.

china self shielding mig wire manufacturers

The Landscape of Self-Shielding MIG Wire Manufacturers in China

China has established itself as a hub for manufacturing welding materials, including high-quality self-shielding MIG wires. Numerous manufacturers across the country are specializing in this segment, leveraging advanced technology and expertise to produce superior products.

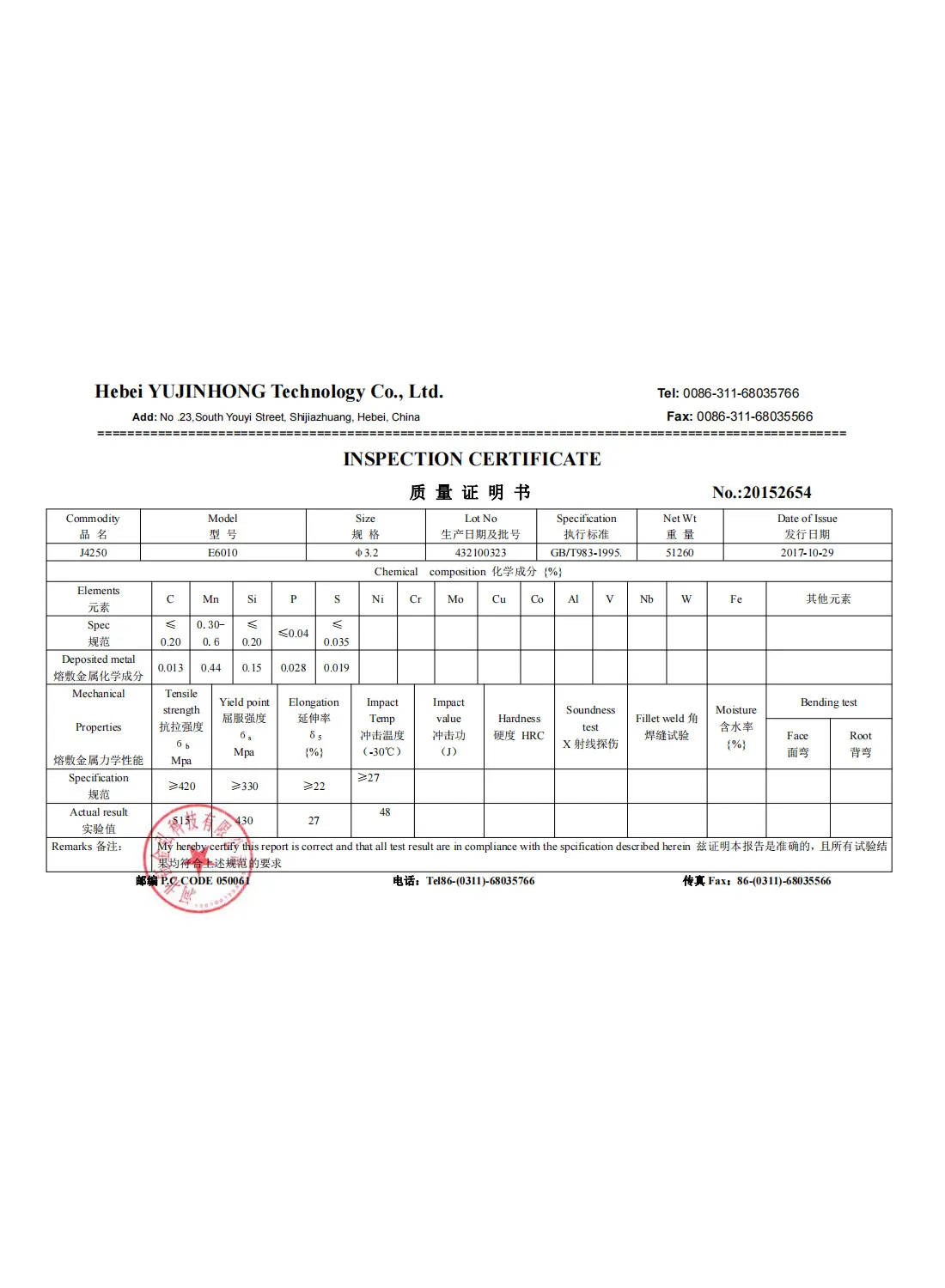

1. Quality and Standards Many Chinese manufacturers adhere to international quality standards, ensuring that their products meet rigorous safety and performance criteria. Certifications such as ISO 9001, AWS, and EN standards are common among reputable manufacturers.

2. Innovation and Technology The industry is marked by continuous innovation, with many manufacturers investing in research and development to enhance the performance and quality of their welding wires. This includes improvements in chemical compositions and wire feeding mechanisms.

3. Diverse Offerings Chinese manufacturers provide a wide range of self-shielding MIG wires tailored for different applications, such as construction, automotive, and heavy machinery. This diversity caters to both local needs and international markets.

4. Competitive Pricing Due to lower production costs and economies of scale, Chinese manufacturers often offer competitive prices, making them attractive options for businesses looking for budget-friendly solutions without compromising quality.

5. Export Market With an increasing global demand for welding materials, many Chinese manufacturers export their self-shielding MIG wires worldwide, establishing a foothold in regions like North America, Europe, and Asia-Pacific.

Conclusion

Self-shielding MIG wire represents a significant innovation in welding techniques, offering numerous benefits that enhance productivity and reduce operational costs. China's prominent position in the manufacturing of this specialized wire reflects the country's capacity for innovation, quality control, and market adaptability. As industries continue to evolve, Chinese self-shielding MIG wire manufacturers are poised to play a pivotal role in meeting the global demand for advanced welding solutions. With continued investment in technology and a commitment to quality, China's influence in the MIG wire market is set to grow, further solidifying its status as a global manufacturing powerhouse.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025