Top manufacturers of welding rods for construction and industrial applications in 2023

The Role and Importance of Welding Rod Manufacturers in the Industry

Welding is an essential process in various industries, including construction, manufacturing, and automotive. At the heart of this process is the welding rod, a crucial component that significantly impacts the quality and strength of the weld. The 6011 welding rod, known for its versatility and reliability, is produced by numerous manufacturers around the world. This article delves into the significance of welding rod manufacturers, particularly those focusing on the 6011 welding rod, and their impact on various industries.

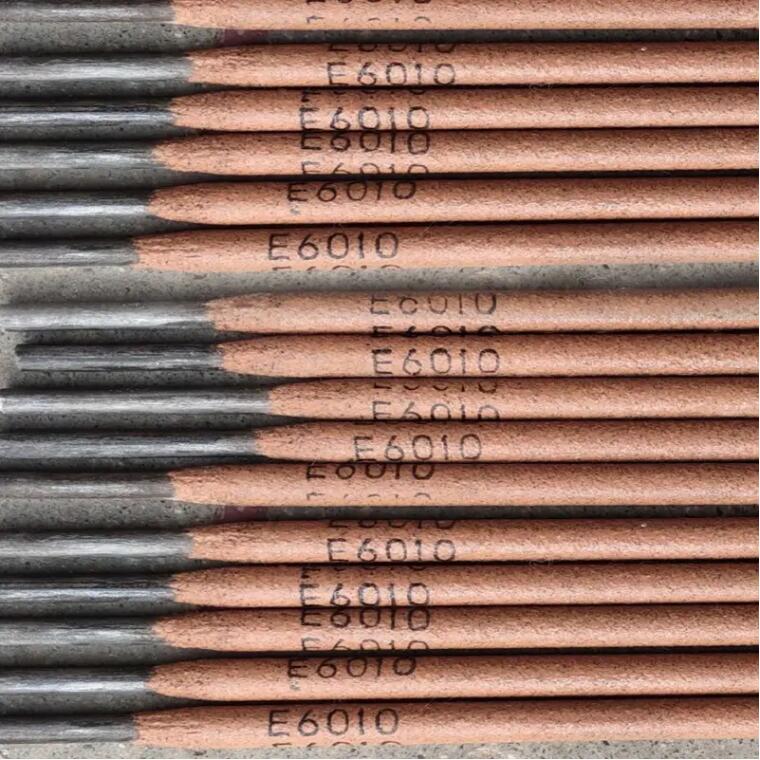

Understanding the 6011 Welding Rod

The 6011 welding rod is a type of electrode that is primarily used for welding mild steel. It is particularly valued for its ability to produce high-quality welds in various positions, making it an ideal choice for professionals and hobbyists alike. The rod is designed to provide a stable arc and deep penetration, which enhances its performance in challenging environments. Additionally, its compatibility with both AC and DC power sources makes it a versatile option for different welding applications.

The Importance of Quality Manufacturing

The quality of welding rods is paramount to ensuring the durability and integrity of welded joints. Manufacturers of 6011 welding rods play a vital role in this aspect by adhering to stringent quality control measures during production. These measures include careful selection of raw materials, precise manufacturing processes, and thorough testing of the finished products. High-quality welding rods minimize the risk of defects, such as porosity and inclusions, which can compromise the strength of the weld.

Leading manufacturers also invest in research and development to enhance the performance properties of their welding rods. For instance, innovations in coating technology can improve arc stability and reduce spatter, making the welding process more efficient. These advancements not only benefit welders by simplifying their work but also contribute to overall project safety and quality.

Meeting Industry Demands

6011 1 8 welding rod manufacturers

Welding rod manufacturers must adapt to the evolving needs of various industries. As sectors such as construction and automotive continue to grow, so does the demand for reliable and high-performance welding rods. Manufacturers are tasked with ensuring their products meet the diverse specifications required by different applications, including thin-walled structures, heavy machinery, and intricate designs.

Manufacturers of 6011 welding rods often focus on understanding market trends and customer requirements. By gaining insight into the specific challenges faced by welders in different sectors, these companies can tailor their products accordingly. This responsiveness to market demands not only strengthens their position in the industry but also fosters long-term relationships with customers.

Environmental and Safety Considerations

In recent years, there has been a growing emphasis on sustainability and safety in manufacturing processes. Leading welding rod manufacturers are increasingly adopting environmentally friendly practices, such as reducing waste and utilizing sustainable materials in production. Additionally, they are committed to ensuring that their products comply with safety regulations, thereby protecting both welders and the environment.

By prioritizing safety and sustainability, welding rod manufacturers contribute to the broader goal of creating a responsible and ethical industry. This shift not only enhances their reputation but also appeals to consumers who are increasingly aware of the importance of environmental stewardship.

Conclusion

Welding rod manufacturers, particularly those specializing in the production of 6011 welding rods, play a crucial role in the welding industry. Their commitment to quality, innovation, and customer satisfaction drives the efficiency and safety of welding operations across various sectors. As industries continue to evolve, these manufacturers will remain integral to meeting the demands of modern welding applications, ensuring that welders have access to the best tools for their work.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025