Top Manufacturers of Wholesale TIG Welding Rods and Wire for High-Quality Welding Applications

Wholesale Welding Wire and TIG Rod Manufacturers A Comprehensive Overview

Welding has been a crucial part of industrial manufacturing for decades, providing the essential link that joins various materials together, ranging from metal structures to intricate machinery. One of the most popular methods for joining metals is through Tungsten Inert Gas (TIG) welding, which offers unparalleled precision and control. At the heart of this process lies a vital component welding wires and TIG rods. This article aims to explore the landscape of wholesale welding wire and TIG rod manufacturers, focusing on their significance, product range, and quality standards.

Understanding TIG Welding

TIG welding is revered in various industries for its ability to produce clean and strong welds. The process involves using a non-consumable tungsten electrode to produce the weld, alongside a filler material that is supplied in the form of welding wire or rods. This method is particularly suitable for thin sections of stainless steel, aluminum, and other non-ferrous metals. For manufacturers and fabricators, the quality of the welding wire or TIG rod directly impacts the overall outcome of the welding process.

The Role of Manufacturers

Wholesale manufacturers of welding wires and TIG rods play a pivotal role in ensuring a steady supply of high-quality materials to various sectors, including automotive, aerospace, construction, and metal fabrication. These manufacturers invest in advanced production technologies and adhere to strict quality control measures to produce products that meet or exceed industry standards.

Product Range and Specifications

Manufacturers typically offer a broad range of welding wires and TIG rods, catering to different applications and materials. For instance, the selection may include

wholesale welding wire tig rod manufacturers

2. Aluminum Welding Wires Specially formulated for aluminum welding, these wires ensure excellent bonding and integrity in the weld.

3. Nickel Alloys Used for high-temperature applications, these rods are designed to withstand severe operational conditions.

4. Mild Steel Wires Commonly used in general fabrication, mild steel wires provide excellent weldability and durability.

Each product comes with specific diameter, length, and composition options, ensuring that clients can find the right materials for their unique projects.

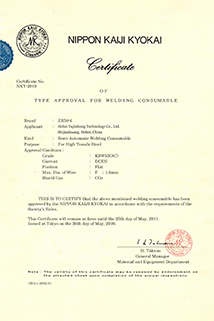

Quality Standards and Certifications

When choosing wholesale welding wire and TIG rod manufacturers, quality assurance is non-negotiable. The best manufacturers are often certified by international standards such as ISO 9001, ensuring that their production processes are standardized and quality is consistently maintained. Additionally, many manufacturers conduct comprehensive testing, including tensile strength, elongation, and impact testing, to guarantee that their products comply with industry regulations and customer expectations.

Conclusion

In conclusion, wholesale welding wire and TIG rod manufacturers are essential partners in the welding and fabrication industry. Their commitment to quality and innovation not only supports diverse manufacturing processes but also enhances the reliability and safety of welded joints in various applications. As industries continue to evolve, the demand for high-quality welding materials will remain steadfast, making the role of these manufacturers increasingly significant in the years to come. Whether you're a small fabricator or a large-scale manufacturer, sourcing your welding materials from reputable wholesale manufacturers is crucial to achieving successful and durable welds.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025