Top Suppliers for 1/16 Inch Welding Rods in China for Quality and Performance

The Landscape of 1/16 Welding Rod Suppliers in China

As the manufacturing industry continues to expand globally, the demand for high-quality welding rods has surged significantly. Among the various sizes and types of welding rods, the 1/16 inch variety has gained prominence due to its versatility and application in multiple sectors. China, being a global manufacturing hub, stands out as a major supplier of these essential welding materials.

The Importance of 1/16 Welding Rods

Welding rods are crucial in the joining of materials, particularly in construction, automotive, and metal fabrication industries. The 1/16 inch welding rod, known for its thin diameter, is especially favored for its ability to provide precise welds in delicate applications. These rods are commonly used in situations where less heat input is necessary, reducing the risk of warping, thus allowing for finer, more accurate welds. Applications range from hobbyist projects to professional industrial applications, showcasing its versatility.

The Supply Chain in China

China's manufacturing prowess enables it to produce welding rods at competitive prices while maintaining quality. The supply chain involves various stages, from raw material sourcing to production, and finally to distribution. Key suppliers in China often utilize advanced technology and rigorous quality control measures to ensure their products meet international standards and specifications.

Major Suppliers and Their Offerings

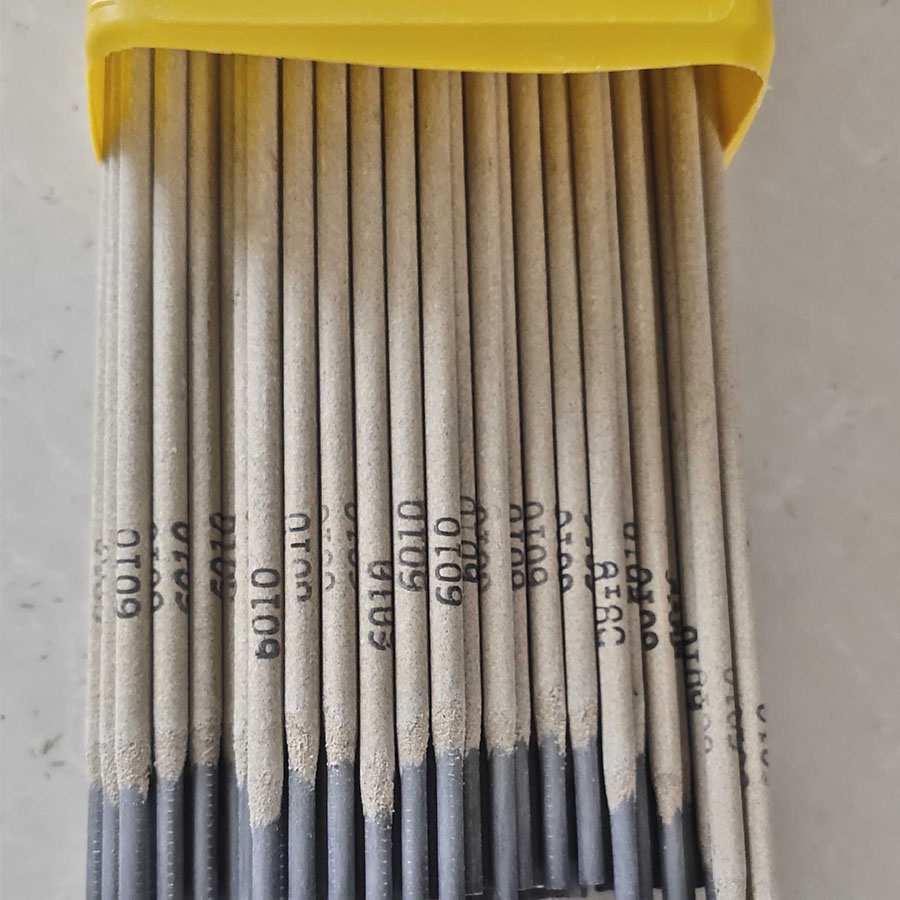

china welding rods 1/16 suppliers

In China, several suppliers specialize in 1/16 welding rods. Companies such as Jinhua Xinyuan Welding Materials and Suzhou Hongtao Welding Industry Co. Ltd. have established themselves as reliable sources of welding rods. These suppliers offer a range of products made from different materials, including mild steel, stainless steel, and specialty alloys. They provide options catered to various applications, and their rods are often compliant with international standards such as AWS (American Welding Society) and ISO certifications.

Additionally, these suppliers typically offer customization options to meet specific client needs. This might include variations in coating materials for different welding processes, such as MIG, TIG, and stick welding. The flexibility in manufacturing allows them to cater to both local and international markets, enhancing their appeal to a broader customer base.

Quality Assurance and Standards

Quality assurance is a key factor for suppliers in China. They employ advanced testing methods to ensure that their welding rods are free from defects and meet precise specifications. Testing methods often include mechanical testing, chemical analysis, and extensive inspections throughout the manufacturing process. Suppliers prioritize adhering to international quality standards, which is crucial for gaining credibility in global markets.

Challenges and Future Prospects

Despite the advantages, the welding rod supply market in China faces challenges such as fluctuating raw material costs, environmental regulations, and competition from other countries. However, the demand for welding rods, particularly 1/16 inch variants, continues to grow as industries expand and innovate. Suppliers are increasingly looking into sustainability options, such as developing eco-friendly welding rods and reducing the carbon footprint of their manufacturing processes.

In conclusion, the landscape of 1/16 welding rod suppliers in China is marked by a combination of innovation, quality assurance, and adaptability. As industries evolve, the need for high-quality welding rods will remain strong, positioning Chinese suppliers as key players in the global market. Their ability to balance quality, cost, and customizability will ensure they continue to meet the demands of a diverse clientele, making them indispensable in the world of welding.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025