Top Suppliers of China 316 Stainless Steel Welding Wire for Quality Welding Solutions

An Overview of China 316 Stainless Welding Wire Suppliers

In the global market of industrial materials and manufacturing, stainless steel plays a crucial role due to its corrosion resistance, durability, and aesthetic appeal. Among the various grades of stainless steel, 316 stainless steel is particularly valued for its high resistance to pitting and crevice corrosion, making it an excellent choice for applications in marine environments, chemical processing, and food production. Consequently, the demand for 316 stainless welding wire, which is used for welding this type of stainless steel, is on the rise. China, known for its robust manufacturing capabilities, has emerged as a key player in supplying 316 stainless welding wire.

The Importance of 316 Stainless Welding Wire

316 stainless welding wire is primarily used in welding applications that require high strength and excellent corrosion resistance. Its chemical composition includes molybdenum, which enhances its resistance to chloride-induced corrosion, a significant factor in marine and coastal applications. Industries such as oil and gas, pharmaceuticals, and construction frequently use this type of welding wire. Thus, sourcing quality 316 stainless welding wire is critical for manufacturers to ensure the integrity and longevity of their products.

The Landscape of Chinese Suppliers

China boasts a vast and diverse range of suppliers for 316 stainless welding wire. From large-scale manufacturers to specialized suppliers, the country's production capabilities are impressive. Many companies utilize advanced technologies and adhere to international standards, ensuring that the welding wire produced meets rigorous quality requirements. Furthermore, China's manufacturing infrastructure allows suppliers to offer competitive pricing without compromising on quality, making them appealing options for local and international buyers.

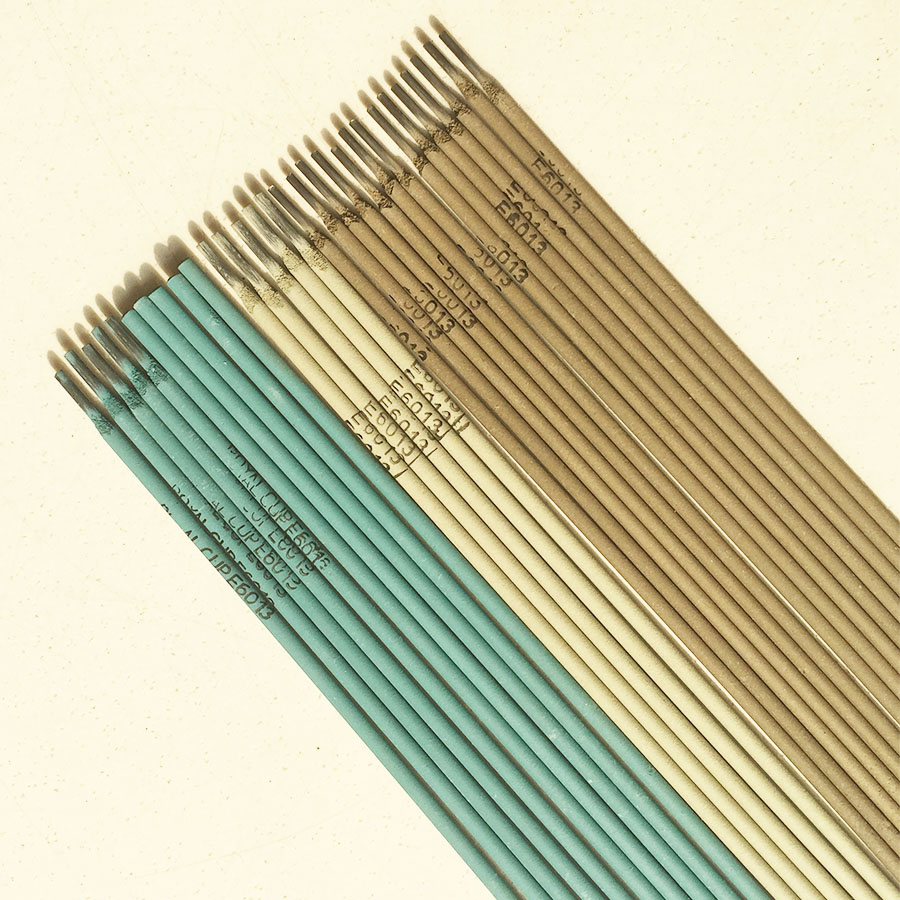

china 316 stainless welding wire suppliers

Quality Standards and Certifications

When sourcing 316 stainless welding wire from China, quality control is paramount. Most reputable suppliers adhere to well-defined quality standards and frequently obtain certifications such as ISO 9001 or ASME qualifications. These certifications are indicative of a company's commitment to quality management and its ability to consistently provide products that meet customer expectations. Additionally, buyers should look for detailed product specifications, including mechanical properties and chemical composition, to ensure that the welding wire meets the necessary application requirements.

Challenges and Considerations

Despite the advantages of sourcing from Chinese suppliers, buyers should also be aware of potential challenges. The variation in quality among suppliers is significant, meaning that due diligence is essential. Verifying supplier credentials, evaluating past customer reviews, and requesting samples can provide insights into a supplier's reliability. It's also crucial to consider logistical factors, such as shipping costs and lead times, which can affect production schedules.

Conclusion

The demand for 316 stainless welding wire continues to grow, driven by its versatile applications and superior properties. China's suppliers play a vital role in meeting this demand, offering a wide array of options for businesses across different industries. By focusing on quality, adhering to standards, and conducting thorough research, companies can successfully tap into the advantages of sourcing 316 stainless welding wire from China. As the global market evolves, so too will the opportunities for suppliers and manufacturers in this critical segment of the metal industry.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025