Top Wholesale Suppliers for Aluminum Stick Welding Products and Equipment at Competitive Prices

Wholesale Stick Welding Aluminum Suppliers A Comprehensive Guide

In the modern manufacturing landscape, aluminum has become a favored material due to its lightweight, strength, and resistance to corrosion. As industries continue to adopt aluminum for various applications, the demand for efficient and reliable welding techniques has surged. Stick welding, or MMA (Manual Metal Arc) welding, is one of the most common methods utilized for aluminum welding, particularly in environments where portable equipment is essential. This has led to a growing market for wholesale stick welding aluminum suppliers.

Understanding Stick Welding

Stick welding involves using a consumable electrode coated in flux to join metal pieces. During the process, the electrode creates an electric arc between itself and the workpiece, generating the heat necessary to melt the aluminum and form a strong bond. This technique is favored for its simplicity, versatility, and cost-effectiveness. However, mastering stick welding, particularly with aluminum, requires skill and precision.

The Role of Wholesale Suppliers

Wholesale suppliers play a crucial role in the welding industry by providing manufacturers, fabricators, and contractors with quality materials and equipment at competitive prices. They procure large quantities of welding rods, machines, and safety gear, making it easier for businesses to access the tools they need without overextending their budgets.

When it comes to aluminum stick welding, suppliers offer a variety of specialized electrodes

. These rods are designed specifically for welding aluminum and ensure strong and durable welds. It is essential for businesses to choose a supplier that correctly categorizes and stocks these essential materials, as the choice of electrode can significantly affect the quality of the weld.Key Considerations When Choosing Suppliers

wholesale stick welding aluminum suppliers

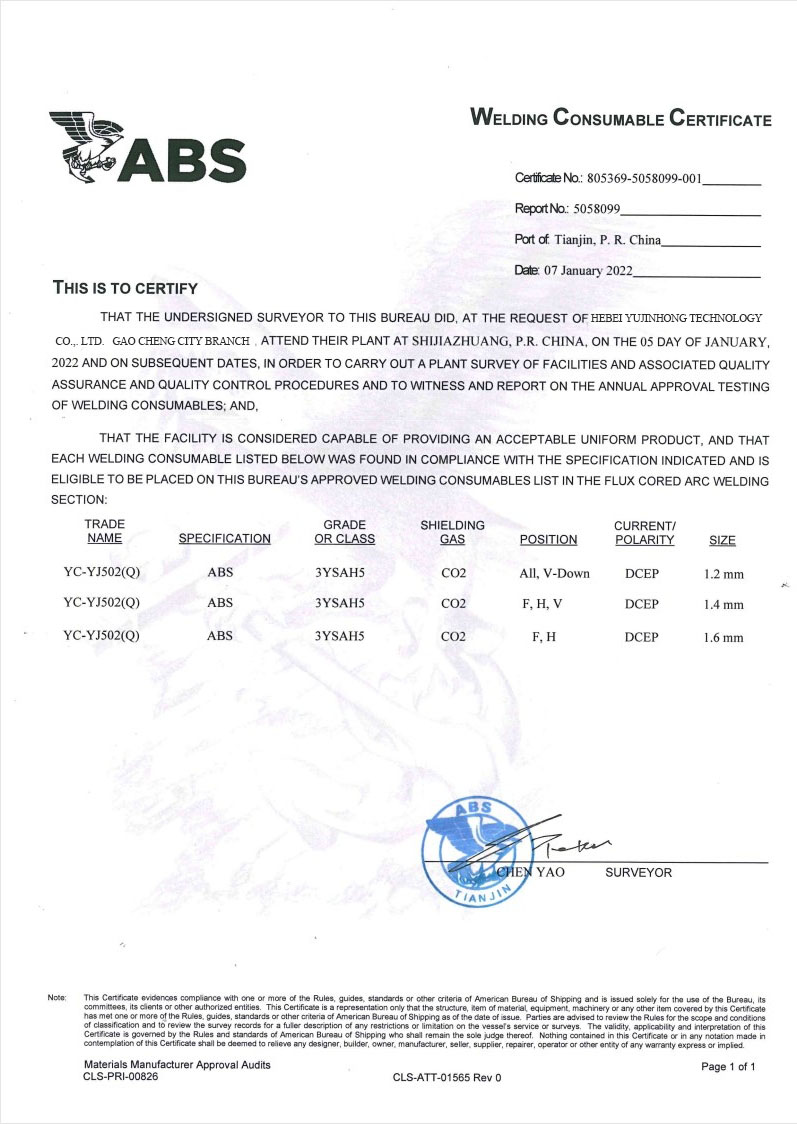

1. Quality of Products It’s vital to source welding materials from suppliers that prioritize quality. Poor-quality rods can lead to weak joints and increase the risk of defects. Reputable suppliers often carry well-known brands and can provide documentation on product standards.

2. Price Competitiveness For businesses operating on tight margins, wholesale pricing is a major factor. Suppliers that can offer bulk discounts and fair pricing models will be more attractive to manufacturers and fabricators.

3. Customer Support Strong customer service is invaluable. Suppliers should be knowledgeable about their products and capable of providing technical support, advice on the best materials for specific applications, and assistance with any issues that arise during the welding process.

4. Delivery and Logistics Timely delivery is critical in the manufacturing sector. Suppliers that have a reliable logistics network can ensure that businesses receive their orders promptly, reducing downtime and keeping production schedules on track.

5. Reputation Researching potential suppliers for their industry reputation is crucial. Online reviews, testimonials from previous customers, and case studies can provide insights into a supplier’s reliability and product effectiveness.

The Future of Wholesale Welding Suppliers

As technology advances, the landscape of welding is evolving. Automation and robotic welding are becoming more common, and suppliers are beginning to adapt to these changes by offering new equipment and advanced materials. Additionally, with a growing emphasis on sustainability, suppliers are also focusing on providing ecologically friendly welding products.

In conclusion, the market for wholesale stick welding aluminum suppliers is integral to supporting industries that rely heavily on aluminum fabrication. Choosing the right supplier involves careful consideration of product quality, pricing, customer service, and reliability. As the industry continues to evolve, those who stay informed and proactive in their supplier partnerships will be better positioned to thrive in a competitive marketplace.

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025