Understanding E6013 Welding Electrodes and Their Applications in Various Welding Projects

Understanding E6013 Welding Electrodes

Welding is a critical process in various industries, especially in construction, manufacturing, and repair work. One of the essential components in welding is the electrode, which serves as the filler material to create a strong and durable bond between metal pieces. Among the numerous types of welding electrodes available, the E6013 electrode is widely recognized and used. This article aims to provide a comprehensive overview of E6013 welding electrodes, including their characteristics, applications, and advantages.

What is E6013?

The designation number E6013 provides important information about the electrode's composition and usability. The E stands for electrode, while the 60 indicates a minimum tensile strength of 60,000 psi. The 1 signifies that it can be used in all positions of welding, and the last 3 reflects the type of coating on the electrode, which affects its usability and arc characteristics.

The E6013 electrode is known for its versatile nature, making it suitable for various welding processes, especially Shielded Metal Arc Welding (SMAW). Its coating typically consists of a mixture of minerals and cellulose, which helps produce a stable arc and good bead appearance. This coating also provides a protective slag that shields the weld pool from contamination, resulting in high-quality welds.

Characteristics of E6013 Electrodes

1. Versatility E6013 electrodes are suitable for welding thin sections of mild steel, making them ideal for light to medium-duty applications. They can be used in flat, vertical, and overhead positions, adding to their adaptability.

2. Ease of Use One of the standout features of E6013 electrodes is their user-friendliness. Welders, both beginners and experienced, appreciate the ease with which they can create stable arcs. The electrodes also produce minimal spatter, which reduces post-weld cleanup time.

3. Good Weld Appearance The E6013 produces clean welds with a smooth finish and good bead appearance. The slag that forms during the welding process is easy to remove and does not require extensive post-weld treatment.

4. Suitable for Various Welding Positions The ability to perform in all positions ensures that welders can use E6013 electrodes for various projects without needing to switch electrodes based on the position of the weld.

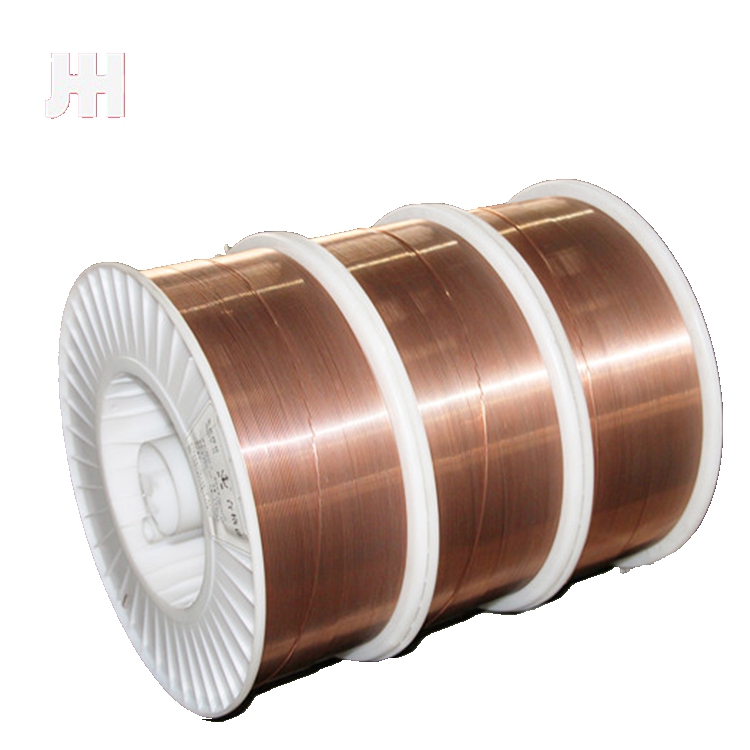

e6013 welding electrodes

Applications of E6013 Electrodes

E6013 electrodes find applications in numerous fields, including

- Construction They are commonly used in constructing metal frameworks, where structural integrity is paramount. - Automotive Welding automotive components, including chassis and body parts, often employs E6013 electrodes due to their reliability. - Maintenance and Repair The ease of use and excellent weld characteristics make E6013 electrodes a preferred choice for repair work in industrial settings and other infrastructures.

Advantages of E6013 Electrodes

1. Cost-effective E6013 electrodes are relatively inexpensive compared to other electrodes, making them a cost-effective choice for many businesses.

2. Availability Due to their popularity, E6013 electrodes are easily available in most welding supply stores, ensuring that welders can find them without difficulty.

3. Reduced Need for Cleaning The reduced spatter and easy-to-remove slag mean that welders spend less time cleaning their workpieces, thus increasing efficiency.

4. Wide Range of Use Their versatility makes E6013 electrodes suitable for a diverse array of welding tasks, allowing for a broader application range.

Conclusion

In conclusion, E6013 welding electrodes are an excellent choice for a variety of welding applications. Their versatility, ease of use, and good weld quality make them a popular option among both novice and experienced welders. Whether in construction, automotive, or maintenance and repair, E6013 electrodes have proven to be reliable and effective, ensuring strong and durable welds across multiple projects. Understanding their characteristics and applications can help welders make informed decisions and achieve better results in their work.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025