Jun . 21, 2024 12:49

Back to list

Welding Electrode Producer

Welding Electrode Manufacturers A Crucial Link in the Supply Chain

In the vast world of manufacturing, the role of welding electrode manufacturers is often overlooked. Yet, these unsung heroes play a pivotal role in the production process, ensuring the seamless flow of raw materials into finished goods. From the construction industry to automotive manufacturing, the demand for high-quality welding electrodes is relentless.

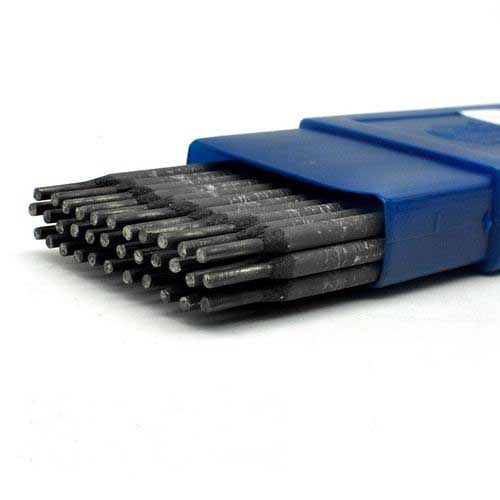

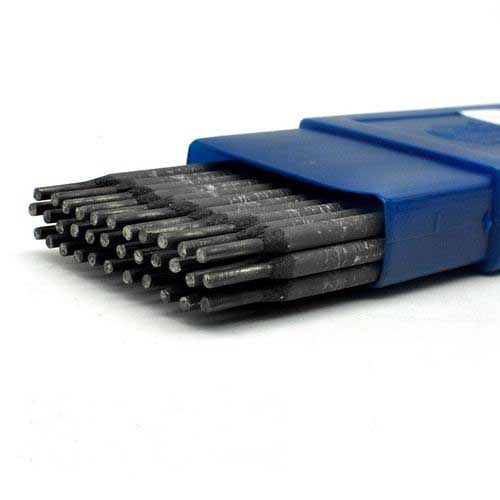

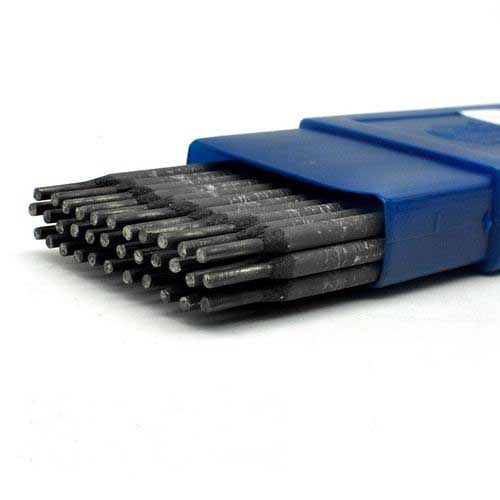

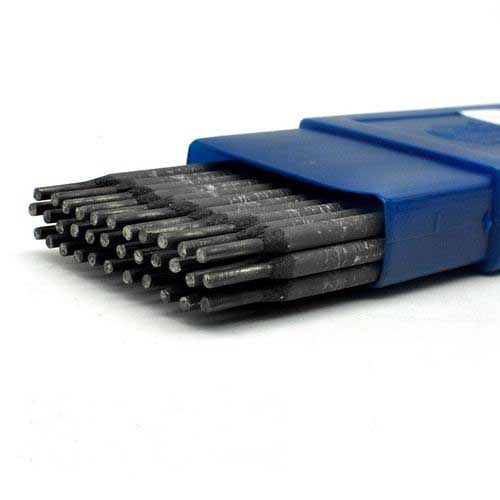

Welding electrodes are essential components used in the joining of metals through the process of fusion welding. They come in various types, including stick, wire, and flux-cored electrodes, each with its unique properties and applications. The composition of these electrodes, which typically includes metal powder, flux, and binder, determines their welding characteristics such as arc stability, weld penetration, and bead shape.

The manufacturing process of welding electrodes is intricate and requires precision. Raw materials must be carefully selected and mixed in the right proportions to ensure the desired chemical and physical properties. The mixing process is followed by shaping, where the mixture is formed into the desired electrode shape. This can be done through extrusion, casting, or pressing, depending on the type of electrode being produced.

Once the electrodes have been shaped, they undergo a series of quality control tests to ensure they meet the required standards

Once the electrodes have been shaped, they undergo a series of quality control tests to ensure they meet the required standards Once the electrodes have been shaped, they undergo a series of quality control tests to ensure they meet the required standards

Once the electrodes have been shaped, they undergo a series of quality control tests to ensure they meet the required standards

Once the electrodes have been shaped, they undergo a series of quality control tests to ensure they meet the required standards

Once the electrodes have been shaped, they undergo a series of quality control tests to ensure they meet the required standards welding electrode manufacturer. These tests may include visual inspection, chemical analysis, and mechanical testing to determine their strength and weldability. Only after passing these rigorous tests are the electrodes ready for distribution to customers.

Welding electrode manufacturers must stay abreast of the latest technological advancements in the field to remain competitive. This includes investing in research and development to create new electrode formulations that offer improved performance and efficiency. They must also be responsive to changing market demands, such as the shift towards more sustainable manufacturing practices.

In conclusion, welding electrode manufacturers are critical players in the supply chain, providing the raw materials necessary for the production of welded metal products. Their attention to detail, commitment to quality, and continuous innovation make them indispensable partners for manufacturers across various industries. As the demand for high-quality welded products continues to grow, the role of these manufacturers will only become more prominent.

welding electrode manufacturer. These tests may include visual inspection, chemical analysis, and mechanical testing to determine their strength and weldability. Only after passing these rigorous tests are the electrodes ready for distribution to customers.

Welding electrode manufacturers must stay abreast of the latest technological advancements in the field to remain competitive. This includes investing in research and development to create new electrode formulations that offer improved performance and efficiency. They must also be responsive to changing market demands, such as the shift towards more sustainable manufacturing practices.

In conclusion, welding electrode manufacturers are critical players in the supply chain, providing the raw materials necessary for the production of welded metal products. Their attention to detail, commitment to quality, and continuous innovation make them indispensable partners for manufacturers across various industries. As the demand for high-quality welded products continues to grow, the role of these manufacturers will only become more prominent.

Once the electrodes have been shaped, they undergo a series of quality control tests to ensure they meet the required standards

Once the electrodes have been shaped, they undergo a series of quality control tests to ensure they meet the required standards

Once the electrodes have been shaped, they undergo a series of quality control tests to ensure they meet the required standards

Once the electrodes have been shaped, they undergo a series of quality control tests to ensure they meet the required standards welding electrode manufacturer. These tests may include visual inspection, chemical analysis, and mechanical testing to determine their strength and weldability. Only after passing these rigorous tests are the electrodes ready for distribution to customers.

Welding electrode manufacturers must stay abreast of the latest technological advancements in the field to remain competitive. This includes investing in research and development to create new electrode formulations that offer improved performance and efficiency. They must also be responsive to changing market demands, such as the shift towards more sustainable manufacturing practices.

In conclusion, welding electrode manufacturers are critical players in the supply chain, providing the raw materials necessary for the production of welded metal products. Their attention to detail, commitment to quality, and continuous innovation make them indispensable partners for manufacturers across various industries. As the demand for high-quality welded products continues to grow, the role of these manufacturers will only become more prominent.

welding electrode manufacturer. These tests may include visual inspection, chemical analysis, and mechanical testing to determine their strength and weldability. Only after passing these rigorous tests are the electrodes ready for distribution to customers.

Welding electrode manufacturers must stay abreast of the latest technological advancements in the field to remain competitive. This includes investing in research and development to create new electrode formulations that offer improved performance and efficiency. They must also be responsive to changing market demands, such as the shift towards more sustainable manufacturing practices.

In conclusion, welding electrode manufacturers are critical players in the supply chain, providing the raw materials necessary for the production of welded metal products. Their attention to detail, commitment to quality, and continuous innovation make them indispensable partners for manufacturers across various industries. As the demand for high-quality welded products continues to grow, the role of these manufacturers will only become more prominent. Latest news

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025