Welding Rod 2.0 mm – Low Spatter, High Strength, Easy Arc

Field Notes on the 2.0mm E6013: the small rod that does big work

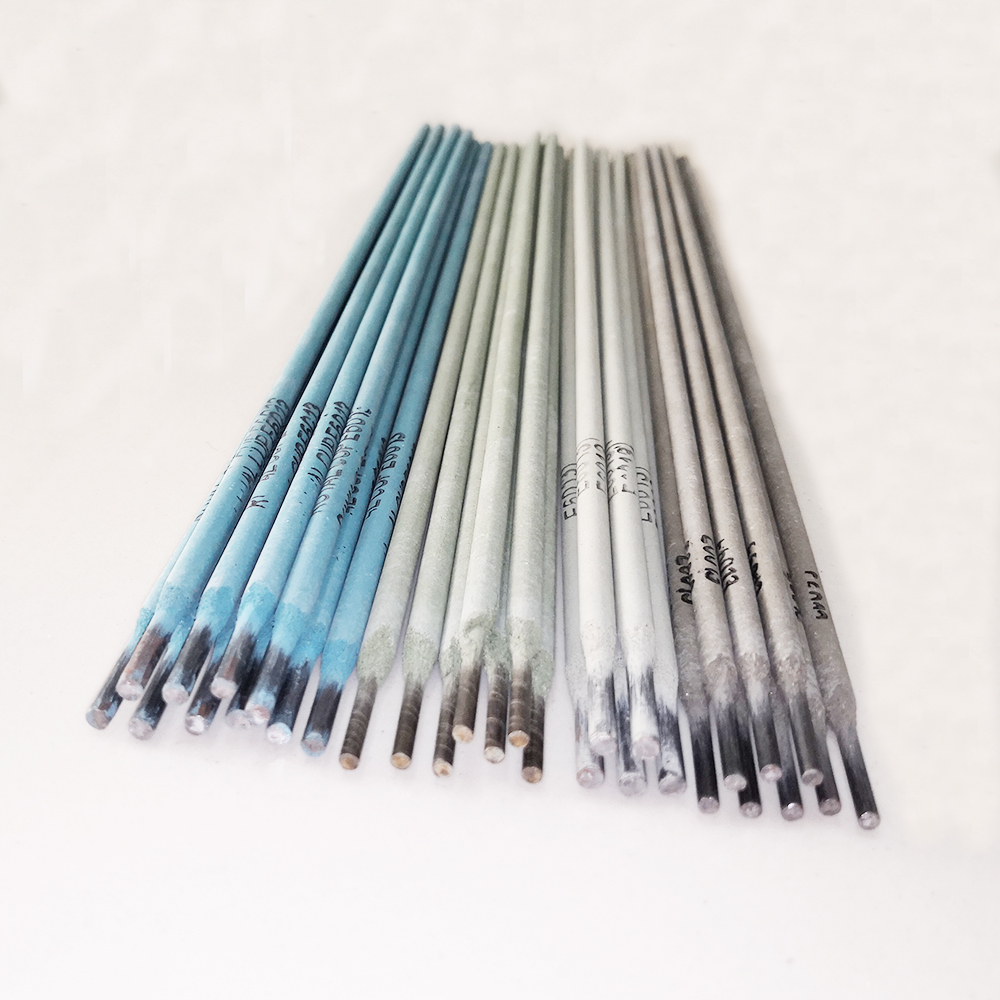

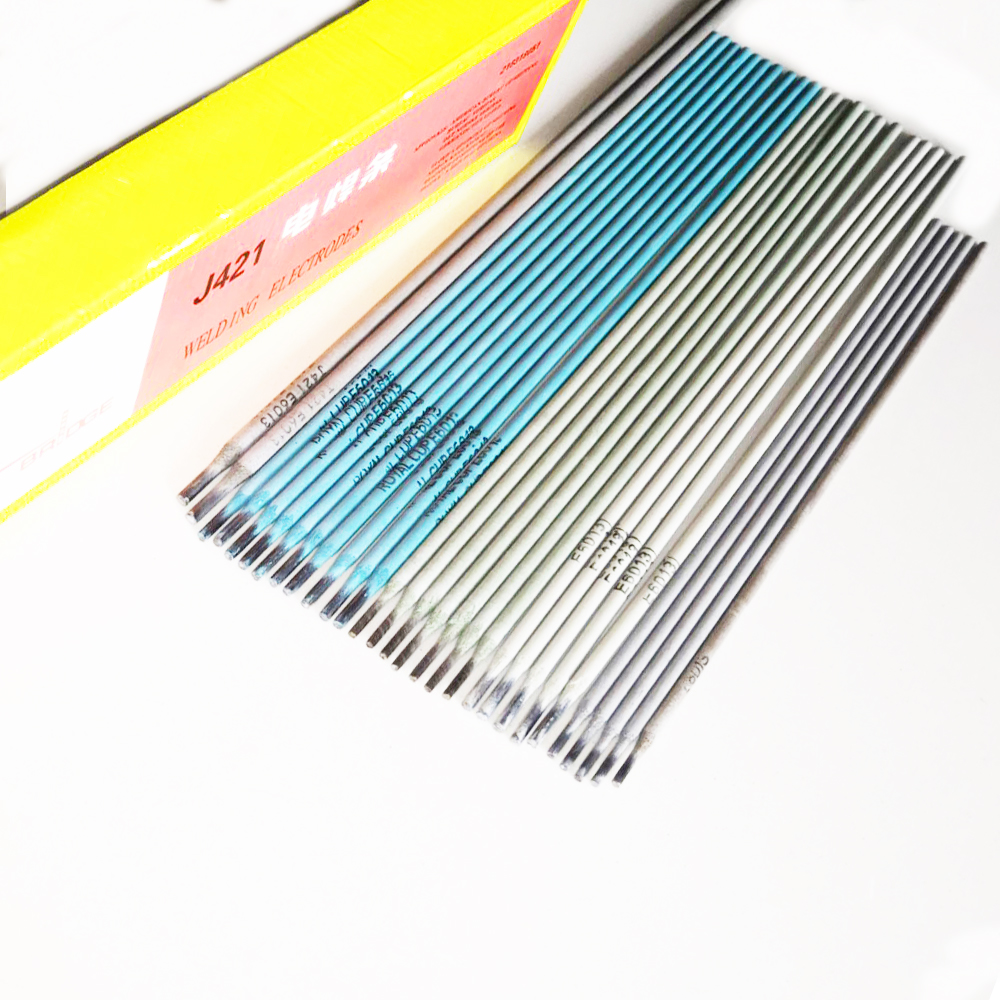

When someone asks me what to use for thin sheet and tidy fillets, my mind goes straight to the welding rod 2.0 mm. I’ve watched fabricators baby-stepping amperage and still laying smooth beads with it. In fact, the 2.0mm refers to the iron core diameter; the coating sits on top and doesn’t count toward that number—an easy detail to miss, to be honest.

Product snapshot: 2.0mm (5/64”) E6013 electrodes, rutile-coated, AC/DC-friendly, manufactured in NO.368 YOUYI NORTH STREET, XINHUA DISTRICT, SHIJIAZHUANG CITY, CHINA. There’s no fixed rule for how thin you can weld with a welding rod 2.0 mm, but real-world shops push it surprisingly far on light-gauge steel with the right hand speed and arc length.

Why 2.0mm E6013 is trending

Across small fabrication, ag repair, and HVAC, there’s a shift toward compact, low-heat inputs. People want cleaner beads on 1.0–2.5 mm stock without cratered edges. E6013 fills that niche: fast-freeze enough for verticals, forgiving slag, and a pleasant arc. Many customers say the restart is easier than they expected—nice when you’re tack-then-stitching frames.

Product specifications (typical)

| AWS/ASME Classification | E6013 (AWS A5.1) |

| Core diameter | 2.0 mm (5/64”) ≈ core only |

| Coating type | Rutile-potassium |

| Polarity | AC, DCEN/DCEP |

| Recommended current | ≈ 30–60 A (real-world use may vary) |

| Weld positions | F, H, V, OH |

| All-weld metal tensile | ≈ 420–510 MPa |

| Length options | 250–300 mm |

| Shelf life | 12 months sealed; rebake if damp (110–150°C, ≈1 h) |

From powder to pallet: process flow

Materials: low-carbon steel core wire; rutile, potassium silicate binder, cellulose, and deoxidizers. Methods: wire cleaning → coating slurry mix → extrusion → low-temp drying → calibrated baking → lot coding. Testing: coating concentricity, moisture (≤0.6% target), arc stability trials, all-weld metal tensile, bend test (180°), slag detach rating. Standards referenced: AWS A5.1 E6013; ISO 2560-A equivalents. Service life in-shop is typically 1–3 years if kept dry; performance drops fast if rods pick up moisture, so mind storage.

Where it shines

- Thin sheet: 1.0–2.5 mm automotive skins, ducting, cabinets.

- Field repairs: gates, brackets, small farm implements.

- Light structural tack-ups and cosmetic fillets.

- Overhead/vertical passes where spatter control matters.

Tip from the floor: keep a short arc, move fast, 35–45 A on 1.2–1.6 mm sheet; pause only to wet the toes. With a welding rod 2.0 mm, lingering is how you blow through.

Vendor comparison (snapshot)

| Vendor | Lead time | Customization | Certs/Compliance | Notes |

|---|---|---|---|---|

| Steel Tools China | ≈ 2–4 weeks | OEM print, length, packaging | AWS A5.1 conformity; ISO 9001 QA claimed | Consistent arc start; responsive MOQs |

| Regional Brand A | 3–6 weeks | Limited branding | AWS label; EN 13479 info on request | Good for AC buzz boxes |

| Import Line B | ≈ 5–8 weeks | Bulk only | Basic test sheets | Price-first; variable slag peel |

Customization and QC

Options include core wire chemistry tuning, coating tweaks for arc softness, 250/300 mm lengths, white-label boxes, and moisture-resistant packaging. Batch QC typically includes: 180° bend—no cracks; porosity counts ≤ AWS limits; diffusible hydrogen checked per internal procedure (indicative for E6013). Many buyers I speak with want stamped heat/lot codes for traceability—ask for it.

Mini case studies

- Furniture plant: switched to welding rod 2.0 mm at 38 A on 1.2 mm tube; burn-through incidents dropped ≈30%, rework time down 22% (4-week average).

- Harbor maintenance shop: rods rebaked at 120°C after humid storage; arc stability recovered and slag detach improved, verified by bend coupons (V-up) with no surface fissures.

Practical setup notes

For the welding rod 2.0 mm: AC buzz box or small inverter is fine; 30–60 A window, strike soft, keep the arc tight. Clean mill scale at least 10–15 mm around the joint. If rods feel “glassy,” they may be damp—rebake and try again.

Authoritative citations:

- AWS A5.1/A5.1M: Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding (E6013).

- ISO 2560-A: Covered electrodes for manual metal arc welding of non-alloy and fine grain steels.

- EN 13479: Welding consumables — Product safety data.

- ASME Section IX: Welding Procedure and Performance Qualification (for WPS/PQR guidance).

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025