Jun . 15, 2024 18:23

Back to list

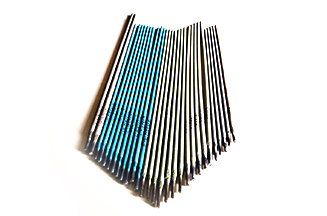

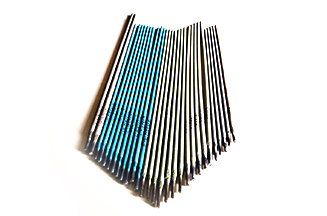

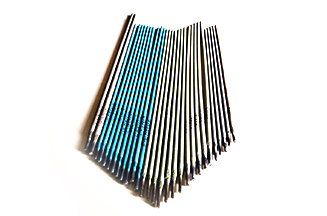

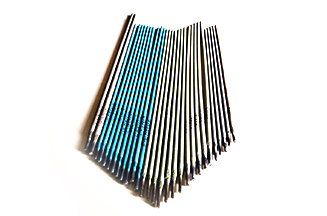

Welding rod factory in China

A Glimpse into China's 3.25mm Welding Rod Manufacturing Landscape

The manufacturing sector in China is renowned for its extensive reach and exceptional quality, with the production of welding rods being no exception. Specifically, the 3.25mm welding rod has become a staple in various industries worldwide due to its reliability and efficiency. This article delves into the intricacies of producing these high-demand welding consumables within Chinese factories.

China's 3.25mm welding rod factories operate on a grand scale, often encompassing vast industrial parks dedicated solely to the production of welding materials. The process begins with the selection of raw materials, primarily steel wires of precise diameters, which serve as the backbone of each rod. Quality control at this stage is paramount; any deviation in material specification could compromise the end product's performance.

Technology plays a crucial role in ensuring the consistent manufacture of these welding rods. Advanced automated machinery precisely draws the steel wire to the required diameter, coats it with a flux formulated to enhance welding properties, and then spools it onto reels for packaging. The flux coating is a critical aspect that distinguishes the quality of Chinese welding rods, offering increased stability and reducing spatter during welding procedures.

Worker skill and experience also significantly impact the production process. Many factories employ technicians who have honed their craft over decades, bringing a level of expertise to the manufacturing process that automation alone cannot replicate Many factories employ technicians who have honed their craft over decades, bringing a level of expertise to the manufacturing process that automation alone cannot replicate Many factories employ technicians who have honed their craft over decades, bringing a level of expertise to the manufacturing process that automation alone cannot replicate Many factories employ technicians who have honed their craft over decades, bringing a level of expertise to the manufacturing process that automation alone cannot replicate

Many factories employ technicians who have honed their craft over decades, bringing a level of expertise to the manufacturing process that automation alone cannot replicate Many factories employ technicians who have honed their craft over decades, bringing a level of expertise to the manufacturing process that automation alone cannot replicate china 3.25mm welding rod factory. These professionals oversee machine operations, perform rigorous quality checks, and maintain equipment to exacting standards.

Sustainability efforts are increasingly visible within these facilities as well. Recognizing the environmental impact of manufacturing, many Chinese welding rod factories are implementing recycling programs and exploring ways to minimize energy consumption during production. It's a testament to China's commitment not only to economic growth but also to responsible stewardship of resources.

The export market for Chinese 3.25mm welding rods is robust, with countries worldwide relying on these factories for their supply of high-quality welding materials. The reputation for reliability and consistent performance precedes these products, ensuring a steady demand that drives continuous innovation and expansion within the industry.

In conclusion, the journey of the 3.25mm welding rod from raw material to finished product is a testament to China's industrial prowess. It reflects an intricate dance between technology, human expertise, and sustainable practices, all converging to satisfy global demands for a essential industrial supply. As these factories continue to evolve, they stand as a symbol of China's ongoing contribution to the world of manufacturing and beyond.

china 3.25mm welding rod factory. These professionals oversee machine operations, perform rigorous quality checks, and maintain equipment to exacting standards.

Sustainability efforts are increasingly visible within these facilities as well. Recognizing the environmental impact of manufacturing, many Chinese welding rod factories are implementing recycling programs and exploring ways to minimize energy consumption during production. It's a testament to China's commitment not only to economic growth but also to responsible stewardship of resources.

The export market for Chinese 3.25mm welding rods is robust, with countries worldwide relying on these factories for their supply of high-quality welding materials. The reputation for reliability and consistent performance precedes these products, ensuring a steady demand that drives continuous innovation and expansion within the industry.

In conclusion, the journey of the 3.25mm welding rod from raw material to finished product is a testament to China's industrial prowess. It reflects an intricate dance between technology, human expertise, and sustainable practices, all converging to satisfy global demands for a essential industrial supply. As these factories continue to evolve, they stand as a symbol of China's ongoing contribution to the world of manufacturing and beyond.

Many factories employ technicians who have honed their craft over decades, bringing a level of expertise to the manufacturing process that automation alone cannot replicate Many factories employ technicians who have honed their craft over decades, bringing a level of expertise to the manufacturing process that automation alone cannot replicate

Many factories employ technicians who have honed their craft over decades, bringing a level of expertise to the manufacturing process that automation alone cannot replicate Many factories employ technicians who have honed their craft over decades, bringing a level of expertise to the manufacturing process that automation alone cannot replicate china 3.25mm welding rod factory. These professionals oversee machine operations, perform rigorous quality checks, and maintain equipment to exacting standards.

Sustainability efforts are increasingly visible within these facilities as well. Recognizing the environmental impact of manufacturing, many Chinese welding rod factories are implementing recycling programs and exploring ways to minimize energy consumption during production. It's a testament to China's commitment not only to economic growth but also to responsible stewardship of resources.

The export market for Chinese 3.25mm welding rods is robust, with countries worldwide relying on these factories for their supply of high-quality welding materials. The reputation for reliability and consistent performance precedes these products, ensuring a steady demand that drives continuous innovation and expansion within the industry.

In conclusion, the journey of the 3.25mm welding rod from raw material to finished product is a testament to China's industrial prowess. It reflects an intricate dance between technology, human expertise, and sustainable practices, all converging to satisfy global demands for a essential industrial supply. As these factories continue to evolve, they stand as a symbol of China's ongoing contribution to the world of manufacturing and beyond.

china 3.25mm welding rod factory. These professionals oversee machine operations, perform rigorous quality checks, and maintain equipment to exacting standards.

Sustainability efforts are increasingly visible within these facilities as well. Recognizing the environmental impact of manufacturing, many Chinese welding rod factories are implementing recycling programs and exploring ways to minimize energy consumption during production. It's a testament to China's commitment not only to economic growth but also to responsible stewardship of resources.

The export market for Chinese 3.25mm welding rods is robust, with countries worldwide relying on these factories for their supply of high-quality welding materials. The reputation for reliability and consistent performance precedes these products, ensuring a steady demand that drives continuous innovation and expansion within the industry.

In conclusion, the journey of the 3.25mm welding rod from raw material to finished product is a testament to China's industrial prowess. It reflects an intricate dance between technology, human expertise, and sustainable practices, all converging to satisfy global demands for a essential industrial supply. As these factories continue to evolve, they stand as a symbol of China's ongoing contribution to the world of manufacturing and beyond. Latest news

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025