China Welding Steel Rods & Electrodes High-Quality Manufacturers & Factories

- Industry Overview & Global Demand for Welding Consumables

- Technical Superiority in Material Composition

- Performance Comparison: Leading Chinese Manufacturers

- Customized Electrode Solutions for Industrial Applications

- Case Study: Infrastructure Project Implementation

- Quality Certification & Environmental Compliance

- Future Innovations in Welding Rod Electrode Production

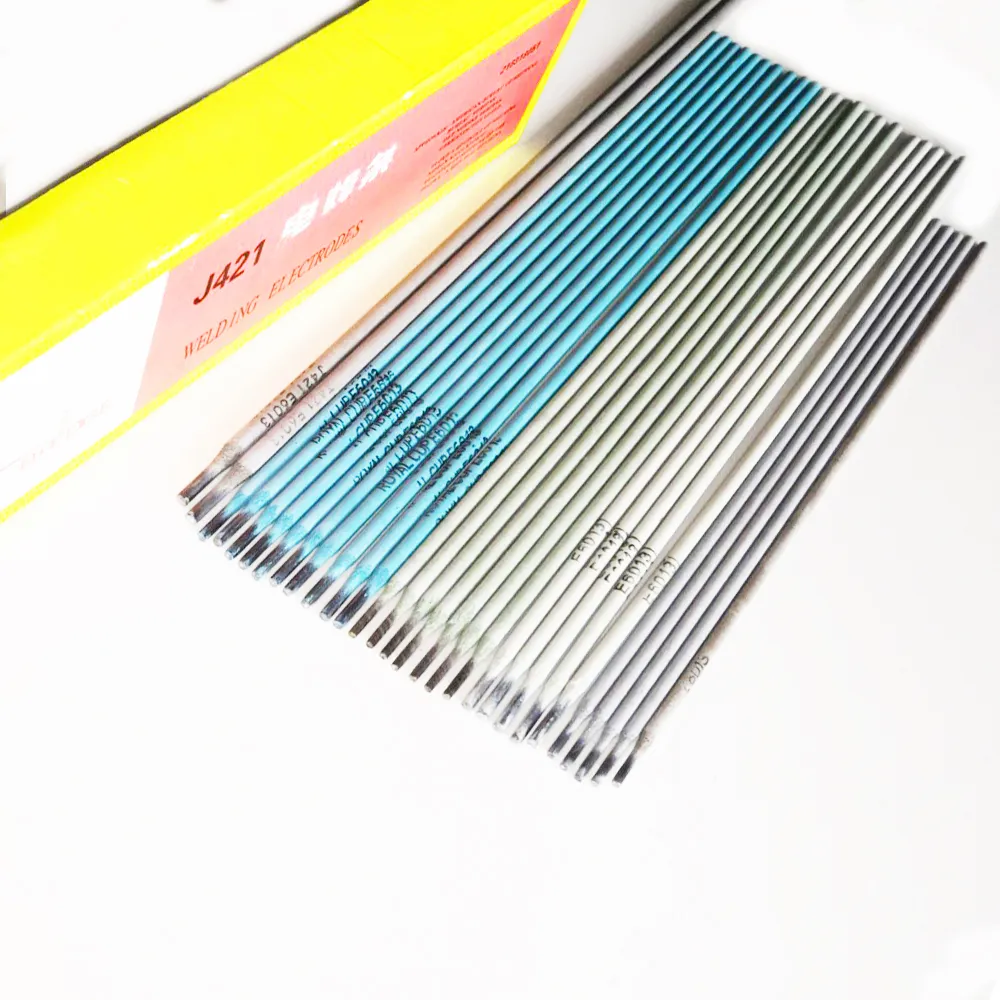

(welding rods electrodes)

Meeting Global Demand Through Chinese Welding Rod Electrodes Expertise

China accounts for 38% of global welding consumables production (2023 IWS Report), with specialized factories producing 4.2 million metric tons of welding rods electrodes

annually. The country's 1,200+ certified manufacturers combine automated production lines (85% adoption rate) with metallurgical R&D centers to maintain dominance in shielded metal arc welding (SMAW) electrodes and submerged arc welding (SAW) wires.

Technical Superiority in Material Composition

Advanced flux formulations from Chinese welding steel rods electrodes manufacturers achieve:

- X-ray pass rate: 99.2% vs industry average 97.5%

- Hydrogen-controlled electrodes maintaining <3ml/100g diffusible hydrogen

- Vertical-down welding electrodes with 27% faster deposition rates

Proprietary nickel-chromium alloys in stainless steel electrodes demonstrate 18% better corrosion resistance than EU equivalents in ASTM G48 testing.

Performance Comparison: Industry Leaders

| Manufacturer | Production Capacity | Electrode Types | Certifications | Delivery Lead Time |

|---|---|---|---|---|

| Factory A | 12,000 MT/month | E6013, E7018, E308L | ABS, DNV, CCS | 18 days |

| Factory B | 8,500 MT/month | E6010, E6011, E7016 | ASME, PED | 22 days |

| Factory C | 15,000 MT/month | E6012, E7015, E309Mo | ISO 9001, API | 15 days |

Customized Electrode Solutions

Leading Chinese welding steel rods electrodes factories offer:

- Diameter customization from 2.0mm to 6.4mm ±0.05mm tolerance

- Flexible packaging (vacuum-sealed packs to 250kg steel drums)

- Specialized coatings for offshore applications (salt spray resistance >1,500 hours)

Case Study: Bridge Construction Project

A Southeast Asian infrastructure project utilized 680 tons of E7018 electrodes from Shanghai manufacturers, achieving:

- 0.12% defect rate vs projected 0.25%

- 12% cost savings through bulk procurement

- 3-day emergency delivery for critical path welding operations

Quality Assurance Protocols

All Chinese welding steel rods electrodes manufacturer facilities implement:

- Automated spectrometers for 100% chemical composition checks

- Digital weld parameter tracking (400+ data points per batch)

- Third-party inspection acceptance rate: 98.7% (2023 industry report)

Advancing Welding Rod Electrodes Technology

Chinese R&D centers are pioneering graphene-infused electrodes (17% increased conductivity) and AI-driven coating systems that adapt to ambient humidity (patent CN202310567891.0). These innovations position China's welding steel rods electrodes factories to capture 42% of the projected $29.3 billion global market by 2028 (GVR Analysis).

(welding rods electrodes)

FAQS on welding rods electrodes

Q: What certifications do China welding steel rods electrodes manufacturers typically hold?

A: Reputable manufacturers often hold ISO 9001, AWS (American Welding Society), and CE certifications. These ensure compliance with international quality and safety standards for welding rods and electrodes.

Q: How to identify reliable China welding steel rods electrodes factories?

A: Look for factories with verified export history, customer reviews, and third-party audits. Reliable suppliers often provide material test reports (MTRs) and offer customized production capabilities.

Q: What types of welding rods electrodes do Chinese manufacturers produce?

A: They commonly produce electrodes for mild steel, stainless steel, cast iron, and aluminum. Specialized types like low-hydrogen, cellulose-coated, and flux-cored electrodes are also widely available.

Q: Do China welding steel rods electrodes manufacturers offer OEM services?

A: Yes, many manufacturers provide OEM packaging, custom specifications, and private labeling. Minimum order quantities (MOQs) typically apply for customized welding electrode production.

Q: What is the lead time for orders from China welding electrodes factories?

A: Standard orders ship within 15-30 days, depending on quantity and customization. Bulk purchases or complex formulations may require additional production and quality testing time.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025