Welding Electrode Wire Suppliers and Their Quality Standards in the Industry

The Importance of Choosing the Right Welding Electrode Wire Manufacturers

When it comes to welding, the quality of the welding electrode wire is paramount. It is not only the welding process that determines the strength and durability of a weld but also the materials used. Thus, selecting the right manufacturers for welding electrode wire is crucial. In this article, we will explore the significance of choosing reputable welding electrode wire manufacturers and the key factors to consider in this decision-making process.

Understanding Welding Electrode Wire

Welding electrode wire is used in various welding processes, such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and stick welding. This wire acts as both the electrode and filler material, helping to bond different metals together. The type of wire used can greatly affect the performance of the weld, the precision of the work, and the overall quality of the finished product.

The Role of Manufacturers

Welding electrode wire manufacturers play a crucial role in ensuring that welders have access to high-quality materials. These manufacturers often specialize in different types of wires, each designed for specific welding applications. Some may focus on mild steel welding, while others may produce wires suitable for stainless steel or aluminum. Each type of wire possesses unique properties that influence how it performs during the welding process.

Quality Assurance and Standards

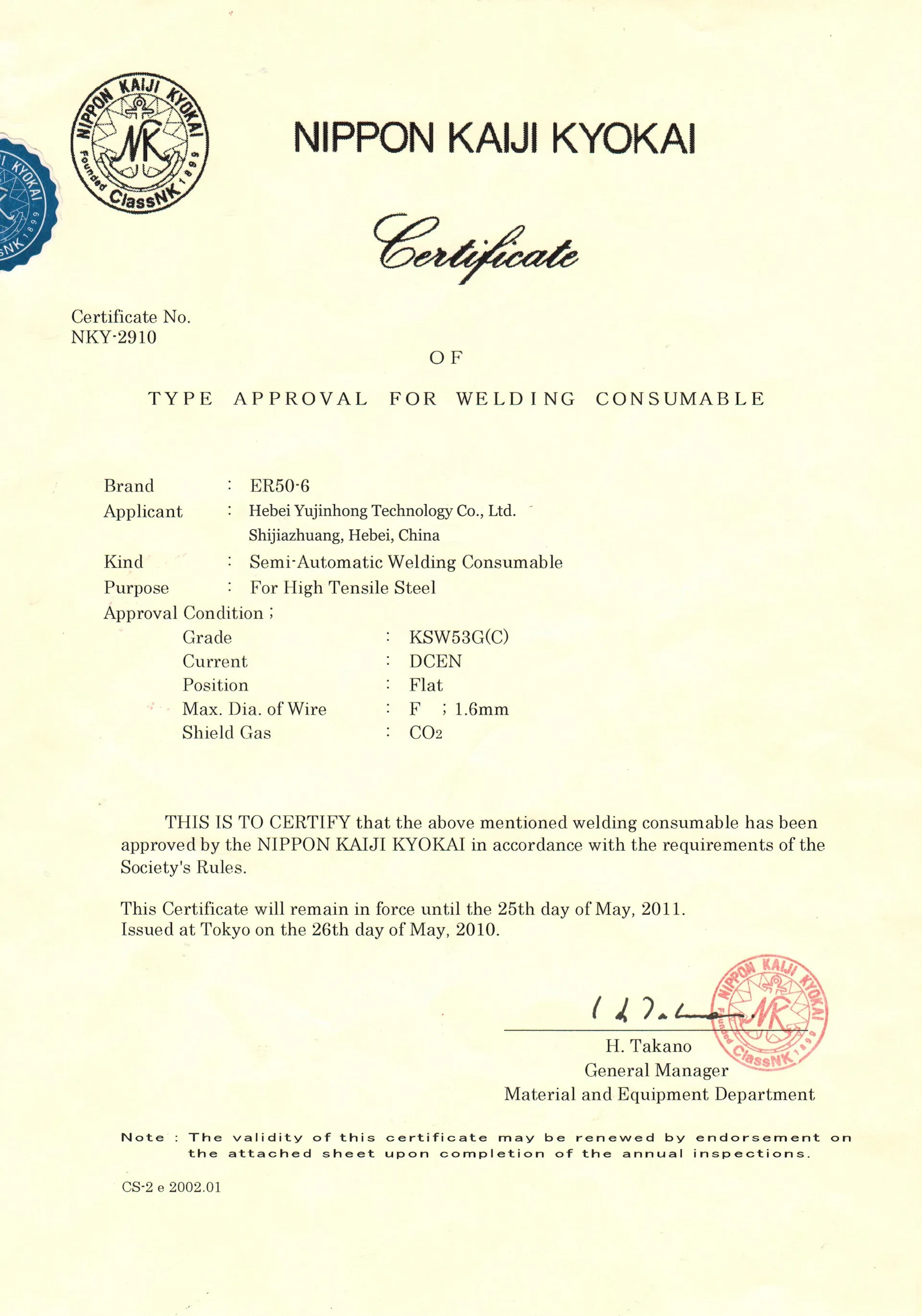

Reputable welding electrode wire manufacturers adhere to strict quality assurance and industry standards. This ensures that their products meet the necessary safety and performance benchmarks. For instance, manufacturers may comply with ISO (International Organization for Standardization) standards, ensuring that their products are consistent and reliable.

When evaluating potential manufacturers, it's essential to inquire about their certification and compliance with recognized standards. A manufacturer with an established reputation for quality is often a safer bet than one without verifiable credentials.

Material Composition

The composition of welding electrode wire can significantly affect the quality of the weld. High-quality wires are often made from pure materials that promote better flow and bonding during the welding process. It’s important to understand the material characteristics, such as tensile strength, melting point, and chemical composition when selecting a manufacturer.

welding electrode wire manufacturers

Choosing a manufacturer that provides detailed material specifications enables welders to choose the right wire for their project, enhancing the quality and safety of the weld.

Customer Support and Technical Assistance

Another crucial factor is the level of customer support and technical assistance provided by the manufacturers. A reliable manufacturer should offer resources that assist welders in selecting the appropriate welding electrode wire based on their needs. This includes guidance on welding processes, machine settings, and the compatibility of wires with various base materials.

Manufacturers that provide technical support foster a strong partnership with their customers, ensuring that welders can achieve the best results possible.

Pricing and Availability

While quality is essential, pricing also plays a significant role in the decision-making process. Many manufacturers offer competitive pricing models, but it’s vital to balance cost with quality. Cheaper options may compromise quality, leading to poor welds and increased expenses in rework or material failure.

Additionally, consider the availability of products. A manufacturer that can reliably supply the necessary welding electrode wire can prevent project delays and keep operations running smoothly.

Conclusion

Choosing the right welding electrode wire manufacturer is critical for any welding operation. The quality of the electrode wire directly influences the welding process and the integrity of the final product. When selecting a manufacturer, consider factors such as quality assurance, material composition, customer support, and pricing.

By investing time in researching potential manufacturers, welders can ensure that they have access to high-quality materials that meet their specific needs. This not only enhances the overall efficiency of the welding process but also contributes to the durability and reliability of the welded structures. In the competitive world of welding, the right choice of electrode wire and manufacturer can set a business apart, leading to successful projects and satisfied customers.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025