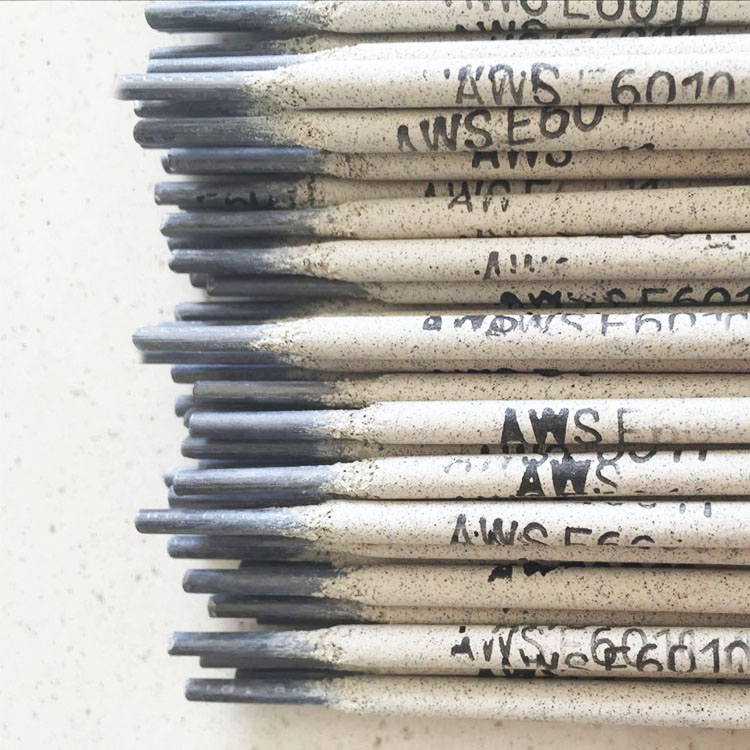

welding rod 6010 factory

The Importance of Welding Rod 6010 in the Industry

Welding is an essential process in various industries, from construction to automotive manufacturing. It involves joining materials, typically metals, by using high heat to melt and fuse them together. The choice of welding rod plays a significant role in determining the quality and strength of the weld. One of the most widely used welding rods in the industry is the E6010 welding rod. This article will delve into the characteristics, applications, and advantages of the E6010 welding rod, particularly focusing on its factory production.

What is Welding Rod 6010?

The E6010 welding rod is often referred to as fast freeze or cellulosic rod. It is an electrode commonly used for shielded metal arc welding (SMAW). The E stands for electrode, followed by the tensile strength (60,000 psi) and the position in which it can be used (1 implies all positions). The rod is coated with a cellulose-based flux which aids in the shielding of the weld pool and helps to create a strong bond.

Characteristics

One of the defining features of the E6010 welding rod is its ability to provide deep penetration, which is crucial for producing strong welds, especially in thin materials. The arc produced by this rod is stable, and it allows for good control, making it suitable for various welding positions, including flat, horizontal, vertical, and overhead.

The welding rod is versatile and can be used on a variety of materials, including mild steel and some alloys. Its ability to work well in environments with poor fit-up conditions further enhances its utility. Additionally, the welds created with E6010 rods have a smooth appearance and are less prone to cracking.

Applications

Welding Rod 6010 is widely used across many sectors, including

1. Construction E6010 is popular in construction projects where structural integrity is crucial. It is commonly used for welding beams, columns, and various structural components.

2. Automotive In the automotive industry, E6010 rods are used for welding chassis frames and other structural components of vehicles.

welding rod 6010 factory

4. Agricultural Equipment Farmers and equipment manufacturers rely on the E6010 welding rod for repairing and fabricating various agricultural machines.

Advantages of E6010 Welding Rod

The E6010 welding rod offers several advantages that make it a preferred choice in the industry

- Deep Penetration The ability to penetrate deeply into the base metal ensures that the weld is strong and resistant to failure under stress.

- Versatility Its effectiveness across various positions and materials means that it can be used in numerous applications without the need for multiple rods.

- Good Arc Stability Welders often appreciate the stable arc produced by the E6010 rod, which contributes to cleaner and more precise welds.

- Ease of Use The fast-freezing characteristics of the E6010 make it easier for welders to work in challenging positions and on thin materials without burning through.

Conclusion

In conclusion, the E6010 welding rod is a critical component in the welding industry, known for its deep penetration abilities and versatility. The factory production of E6010 rods ensures the availability of high-quality electrodes tailored for various welding needs. As industries continue to evolve, the demand for robust and reliable welding solutions like the E6010 will remain strong. Whether used in construction, automotive, or maintenance applications, the E6010 welding rod exemplifies the importance of choosing the right materials to achieve high-quality welds, contributing to the safety and reliability of welded structures and components. For anyone involved in welding, understanding the properties and applications of welding rods like the E6010 is vital to mastering the craft and ensuring successful outcomes in every project.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025