E7018 Welding Rod Providers and Their Best Features

Understanding E7018 Welding Rod Suppliers

Welding is an essential process in various industries, from construction to manufacturing and repair works. One of the most commonly used welding rods in the industry is the E7018. It is a low-hydrogen electrode that is extensively employed for its durability and versatility in welding applications. As demand for welding rods continues to rise, understanding the landscape of suppliers is crucial for manufacturers, tradespeople, and hobbyists alike.

What is E7018?

The E7018 welding rod is a type of stick electrode used for arc welding, particularly in the Shielded Metal Arc Welding (SMAW) process. The E in E7018 stands for electrode, while 70 denotes the minimum yield strength of 70,000 psi. The 1 indicates that the electrode can be used in all positions (flat, horizontal, vertical, and overhead), and 8 refers to the type of coating on the electrode.

E7018 electrodes contain a higher level of manganese and silicon, which contributes to their excellent arc stability and low-hydrogen characteristics. This makes them ideal for welding high-strength steels and critical applications where weld integrity is paramount. Moreover, the low-hydrogen properties minimize the risk of cracking in the weld joint, making E7018 a preferred choice for structural work, pressure vessels, and heavy machinery.

The Importance of Reliable Suppliers

Reliable suppliers of E7018 welding rods play a crucial role in ensuring that craftsmen have access to quality materials. The quality of the welding rod directly affects the strength and integrity of the weld, thereby influencing the overall safety and durability of the construction or manufacturing project.

When selecting a supplier, it is vital to consider several factors

1. Quality Assurance The supplier should provide certifications and assurance of quality control, ensuring that their products meet industry standards. Look for suppliers that adhere to AWS (American Welding Society) standards, specifying compliance with the necessary specifications for E7018 rods.

2. Product Availability Access to a wide range of welding rods, including different diameters and lengths of E7018, is critical for accommodating various applications. Suppliers should have an adequate inventory that allows for immediate fulfillment of orders.

3. Pricing and Value While price is certainly a consideration, it should not be the sole determining factor. It is essential to balance cost with quality to ensure that you are getting value for your investment. Be wary of suppliers that offer products significantly cheaper than the market average, as this may indicate inferior quality.

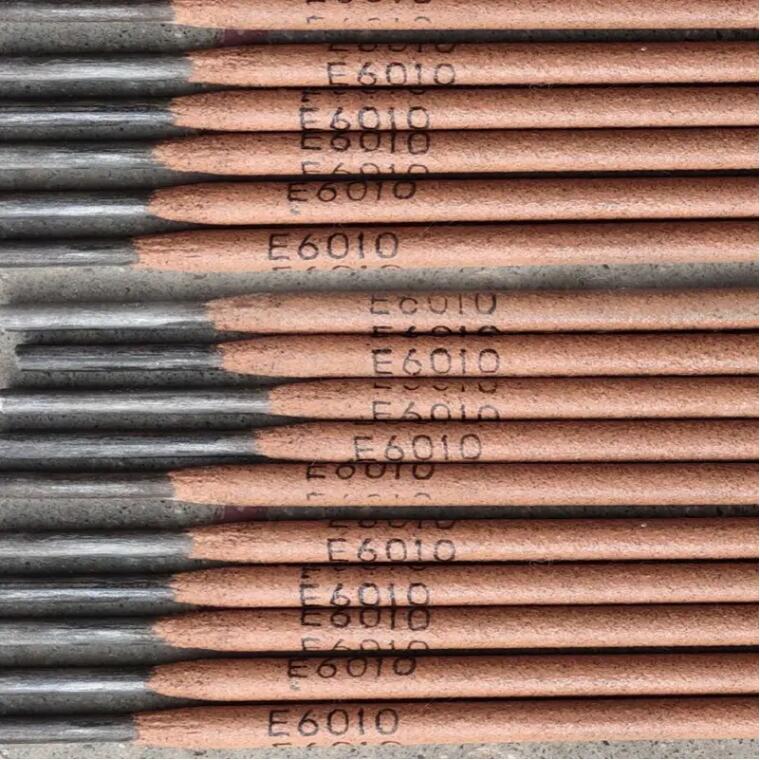

welding rod e7018 suppliers

4. Customer Support Suppliers that offer good customer service can help users select the right products for their specific welding needs. Technical support can be invaluable, particularly for less experienced welders who may benefit from expert guidance.

5. Reputation Researching a supplier’s reputation within the industry can provide insights into their reliability and product quality. Customer reviews, recommendations, and word-of-mouth referrals from other professionals in the field can be highly informative.

Leading E7018 Welding Rod Suppliers

Various companies specialize in welding supplies, including E7018 rods. Some renowned suppliers include

- Lincoln Electric Known for a wide range of welding products, Lincoln Electric offers high-quality E7018 rods with consistent performance and strength.

- Miller Electric Another industry leader, Miller Electric provides E7018 rods that are trusted for structural welding and fabrication across various sectors.

- ESAB With a global presence, ESAB is recognized for its innovative welding solutions, including high-quality E7018 electrodes.

- Hobart Welding Products Hobart offers a range of E7018 welding rods known for their usability and excellent performance in various applications.

Conclusion

In conclusion, the selection of E7018 welding rod suppliers is a critical factor for professionals in the welding industry. By focusing on quality, availability, pricing, customer support, and reputation, welders can ensure they are sourcing the best materials for their projects. With reliable suppliers, craftsmen can confidently tackle even the most demanding welding tasks, producing robust and durable welds that meet industry standards and safety requirements. Whether for large-scale industrial projects or small-scale repairs, knowing where to find high-quality E7018 welding rods is essential for success in the field.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025