Manufacturers of 2.5mm Welding Rods for Various Industrial Applications

The Importance of Welding Rod Factories in Modern Manufacturing

Welding is a critical process in various industries, from construction and automotive to aerospace and manufacturing. At the heart of welding technology lie welding rods, essential components that ensure strong, reliable joints between pieces of metal. As a result, welding rod factories play a pivotal role in the production of these materials.

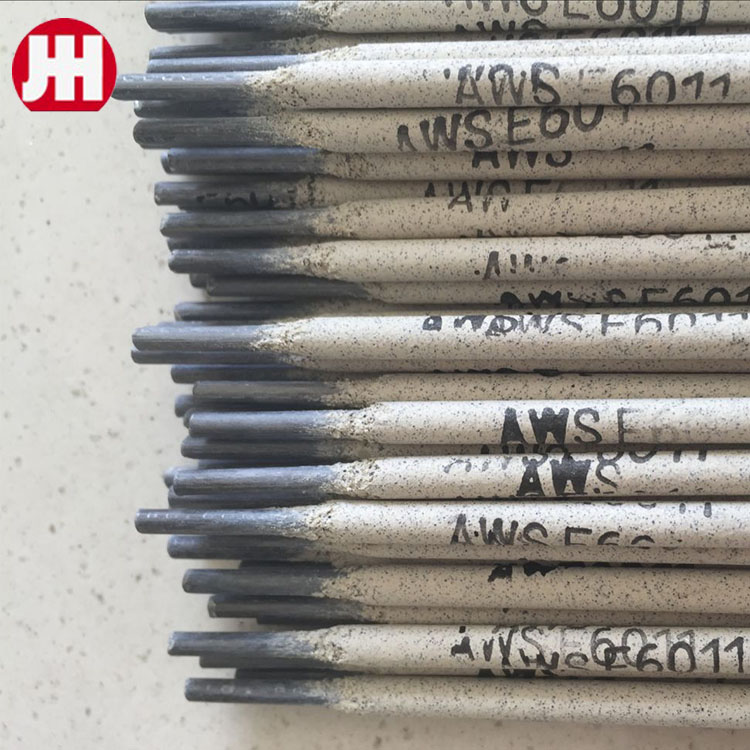

Welding rods, also known as electrodes, are designed to conduct electricity and provide the necessary heat to melt the base metal during the welding process. They come in various compositions, including coated and non-coated types, each engineered for specific applications. The production of welding rods involves careful selection of materials and adherence to strict quality standards to ensure their performance and reliability in high-stress environments.

The Importance of Welding Rod Factories in Modern Manufacturing

Once the materials are sourced, the manufacturing process begins. It often involves processes such as extrusion, drawing, and coating. In the extrusion process, raw metal is heated until pliable and then forced through a die to create the desired rod shape. Following this, the rods undergo a drawing process that increases their length while reducing their diameter, ensuring they meet industry specifications. The final step often includes applying a coating that enhances the rod's performance, providing protection against oxidation and improving its usability in different environments.

welding rods 2.5 factories

Quality control is a cornerstone of welding rod production. Factories implement rigorous testing protocols to ensure that each batch of rods meets the required standards. This includes mechanical tests, such as tensile strength and elongation tests, as well as metallurgical examinations to assess the microstructure of the welds produced by the rods. Such measures help prevent failures in critical applications, safeguarding not only the integrity of the structures being welded but also the safety of workers.

The significant advancements in technology have also transformed the landscape of welding rod manufacturing. Automation and computer-aided design (CAD) have made it possible to optimize production processes, enhance precision, and reduce waste. These innovations enable factories to produce welding rods at a much larger scale while maintaining high quality, allowing them to meet the increasing demand from various sectors.

Moreover, the global market for welding rods has experienced considerable growth, driven by factors such as industrialization, urban development, and the need for infrastructure repair. Companies are continuously evolving to adapt to shifting market demands and technological advancements, leading to an array of new products and formulations that cater to specific applications. For instance, the development of specialized welding rods for high-temperature applications or rods suited for welding dissimilar metals showcases the industry’s responsiveness to diverse welding challenges.

In conclusion, welding rod factories are integral to the modern manufacturing landscape. Their role in producing reliable, high-quality welding rods cannot be overstated, as these materials are fundamental to achieving strong and durable welds. As technology continues to advance and industries evolve, these factories will remain at the forefront, adapting to new challenges and ensuring the safety and efficiency of welding operations worldwide. The future of welding will undoubtedly see further innovations and upgrades in welding rod technology, reflecting the ongoing quest for excellence in manufacturing processes.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025