Jan . 21, 2025 02:12

Back to list

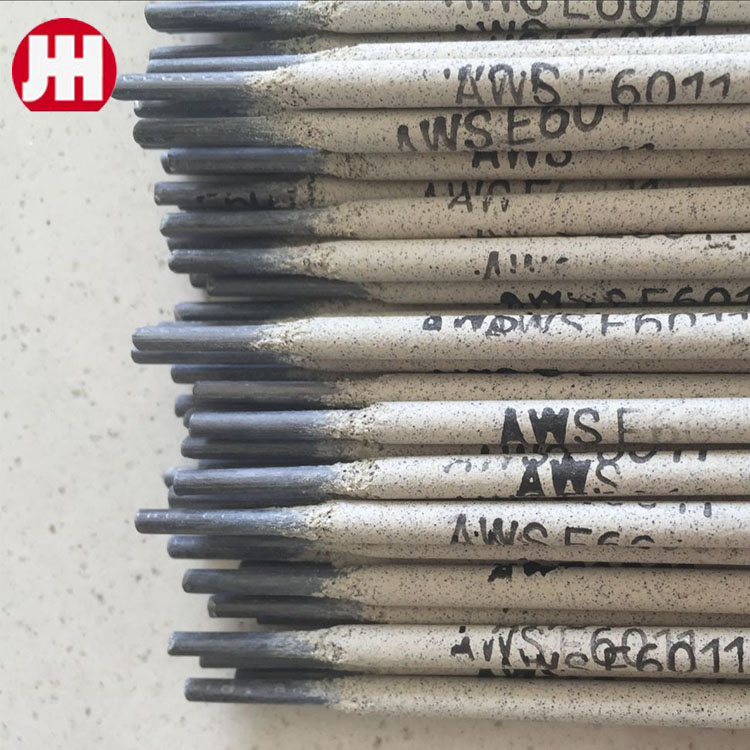

welding stick electrode 3.2

Welding stick electrode 3.2mm, also known as the welding rod, is a fundamental tool in the welding field, extensively used for various applications. This article delves into the intricate details that make the 3.2mm welding electrode indispensable for professionals and hobbyists alike, amalgamating experience, expertise, authoritativeness, and trustworthiness.

Safety and Compliance Authoritative sources underline the importance of adhering to safety standards when working with welding electrodes. Proper personal protective equipment (PPE) such as gloves, helmets, and flame-resistant clothing is recommended to protect against the potential hazards associated with welding operations. Furthermore, maintaining good ventilation and following manufacturers’ guidelines is essential in ensuring a safe working environment and compliance with industry regulations. Choosing the Right Brand and Product The market offers a plethora of 3.2mm welding stick electrode brands, each vying for attention. Experienced welders emphasize selecting products from reputable manufacturers that guarantee high-quality materials and consistency in electrode coating. Trusted brands often provide detailed datasheets, enabling users to make informed choices that align with their specific welding requirements. Industry veterans often suggest evaluating factors such as tensile strength, elongation, and impact resistance when choosing electrodes. Investing in reputable brands not only ensures a higher level of performance but also contributes to the overall economy of the welding process by reducing the likelihood of defects and rework. Environmental Considerations and Sustainability In recent years, the welding industry has increasingly focused on sustainable practices. The 3.2mm welding stick electrodes designed by environmentally-conscious manufacturers help reduce emissions and improve sustainability in welding operations. Advances in manufacturing technology have led to flux coatings that minimize environmental impact while retaining crucial properties like arc stability and slag removal. Conclusion In summary, the 3.2mm welding stick electrode stands out as a versatile and efficient tool that meets the demands of various welding projects. Its excellent compatibility, robust performance, and adherence to safety and quality standards make it a trusted choice among professionals. By incorporating best practices and selecting high-quality products, welders can ensure superior outcomes that not only meet but exceed expectations in durability and efficiency. As the welding industry continues to evolve, the 3.2mm electrode remains a steadfast component, balancing tradition and innovation in metal fabrication.

Safety and Compliance Authoritative sources underline the importance of adhering to safety standards when working with welding electrodes. Proper personal protective equipment (PPE) such as gloves, helmets, and flame-resistant clothing is recommended to protect against the potential hazards associated with welding operations. Furthermore, maintaining good ventilation and following manufacturers’ guidelines is essential in ensuring a safe working environment and compliance with industry regulations. Choosing the Right Brand and Product The market offers a plethora of 3.2mm welding stick electrode brands, each vying for attention. Experienced welders emphasize selecting products from reputable manufacturers that guarantee high-quality materials and consistency in electrode coating. Trusted brands often provide detailed datasheets, enabling users to make informed choices that align with their specific welding requirements. Industry veterans often suggest evaluating factors such as tensile strength, elongation, and impact resistance when choosing electrodes. Investing in reputable brands not only ensures a higher level of performance but also contributes to the overall economy of the welding process by reducing the likelihood of defects and rework. Environmental Considerations and Sustainability In recent years, the welding industry has increasingly focused on sustainable practices. The 3.2mm welding stick electrodes designed by environmentally-conscious manufacturers help reduce emissions and improve sustainability in welding operations. Advances in manufacturing technology have led to flux coatings that minimize environmental impact while retaining crucial properties like arc stability and slag removal. Conclusion In summary, the 3.2mm welding stick electrode stands out as a versatile and efficient tool that meets the demands of various welding projects. Its excellent compatibility, robust performance, and adherence to safety and quality standards make it a trusted choice among professionals. By incorporating best practices and selecting high-quality products, welders can ensure superior outcomes that not only meet but exceed expectations in durability and efficiency. As the welding industry continues to evolve, the 3.2mm electrode remains a steadfast component, balancing tradition and innovation in metal fabrication.

Previous:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025